Production Process

-

01

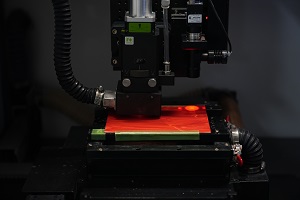

Laser Drilling

Laser Drilling -

02

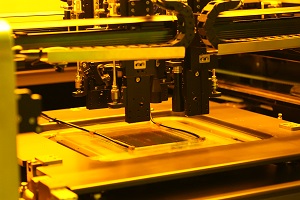

Magnetron Sputtering

Magnetron Sputtering -

03

Grinding Board

Grinding Board -

04

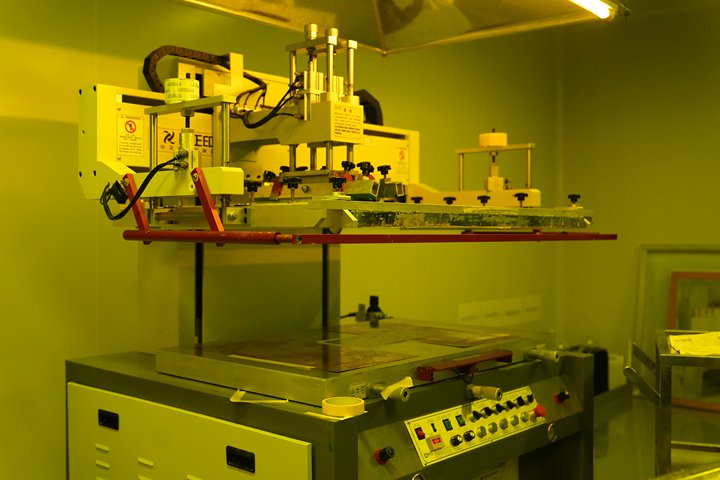

Exposure

Exposure -

05

Electroplating

Electroplating -

06

Des

Des -

07

OSP

OSP -

08

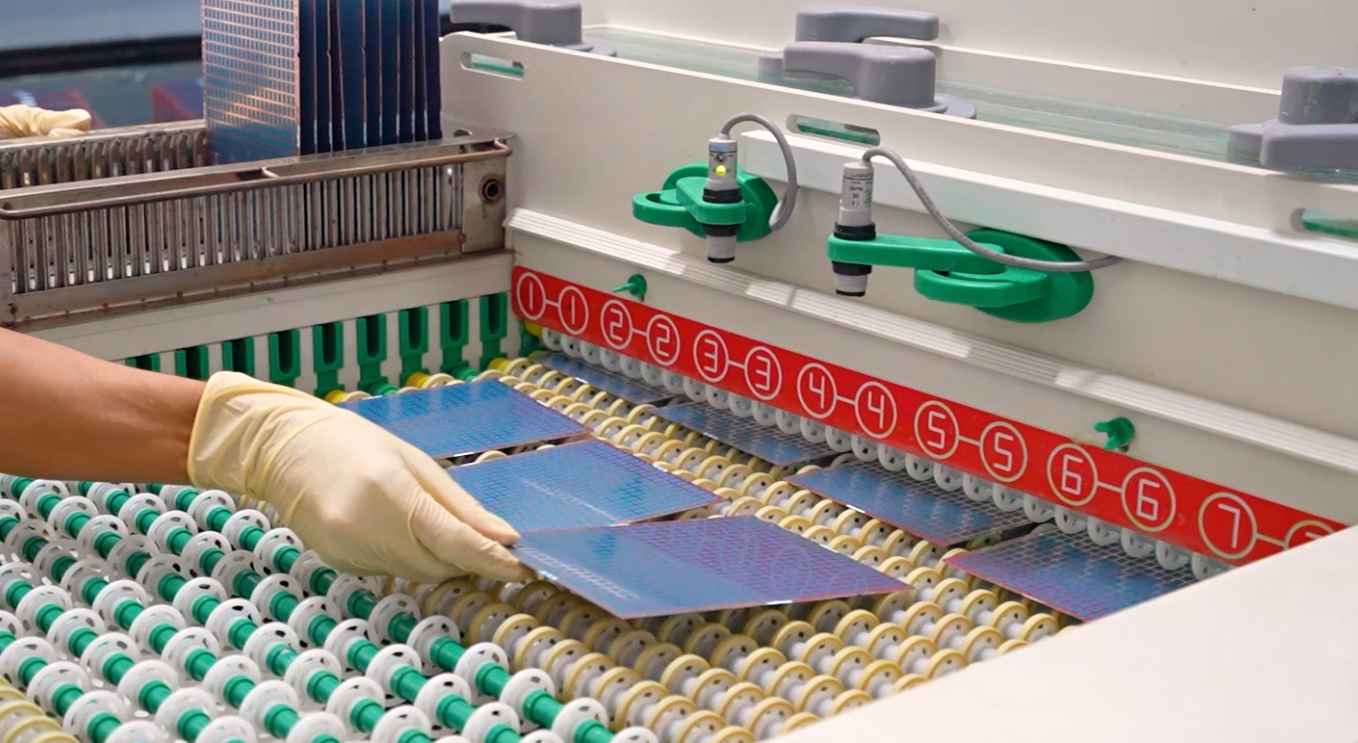

Solder mask printing

Solder mask printing -

09

Flying Probe Testing

Flying Probe Testing -

010

FQC

FQC

Production Process Video Introduction

Be an asset to the community throughunwavering adherence to a social andenvironmental consciousness.Process Capability

| Project | Thick film ceramic board process capabilities | DBC/DCB Copper Copy Ceramics Square Process Capability | DPC direct copper plating ceramic substrate process capacity | AMB activated metal welding ceramic substrate |

|---|---|---|---|---|

| Number of circuit layers | 10 layer | 2 layer | 2 layer | 2 layer |

| Biggest size | 200*200mm | 138*178mm | 138*190mm | 114*114mm |

| Minimum board thickness | 0.25mm | 0.30mm~0.40mm | 0.25mm | 0.25mm |

| Maximum board thickness | 2.0mm | 1L: 1.3mm; 2L: 1.6mm | 2.0mm | 1.8mm |

| Conductor thickness | 5um-13um | 3.9oz-8.6oz | 2um-200um | 8oz-22.9oz |

| Minimum line width/line distance | 6/8mil (0.15/0.20mm) | 12/12mil (0.30/0.30mm) | 6/8mil (0.15/0.20mm) | 20/20mil (0.50/0.50mm) |

| Substrate | One aluminum, aluminum nitride, oxidation, oxide | Alumina, aluminum nitride, oxide | Alumina, aluminum nitride, oxide, silicon nitride | Aluminum nitride, silicon nitride |

| Base material | 0.25, 0.38, 0.50, 0.635, 0.80, 1.0, 1.25, 1.5, 2.0mm | 0.25, 0.38, 0.50, 0.635, 0.76, 1.0mm | 0.25, 0.38, 0.50, 0.635, 0.80, 1.0, 1.25, 1.5, 2.0mm | 0.25, 0.38, 0.50, 0.635, 0.76, 1.0mm |

| Minimum | 4mil (0.1mm) | |||

| Minimum hole distance | NPTH: 16mil (0.30mm); PTH: 20mil (0.5mm) | |||

| Minimum PAD ring (single) | 6mil(0.15mm) | N/A | 3mil(0.075mm) | N/A |

| PTH minimum hole wall copper thickness | 4mil(10um) | N/A | 4mil (10um) | N/A |

| Welding pad minor diameter | 10mil(0.25mm) | 8mil(0.20mm) | 6mil(0.15mm) | 8mil(0.20mm) |

| Group welding bridge | 12mil(0.30mm) | 8mil(0.20mm) | 6mil(0.15mm) | 8mil(0.20mm) |

| BGA pads minimum spacing | 12mil(0.30mm) | 8mil(0.20mm) | 5mil(0.125mm) | 8mil(0.20mm) |

| PTH/NPTH pore diameter tolerance | PTH: ±4mil (0.1mm) ; NPTH: ±2mil (0.05mm) | |||

| Pole bias tolerance | ± 4mil (0.1mm) | |||

| Tolerance | Laser cutting: +0.2/0.05mm; Mold type type: +0.25/0.20mm | Laser cutting: +0.2/0.05mm | Laser cutting: +0.2/0.05mm; Mold type type: +0.25/0.20mm | Laser cutting: +0.2/0.05mm |

| Line width/line distance tolerance | ± 5mil (0.125mm) | ± 5mil (0.125mm) | ± 1mil (0.025mm) | ± 5mil (0.125mm) |

| Surface treatment | AgPd, AuPd, Mn/Ni | OSP antioxidant/nickel plating, Shen Jin | OSP Antioxidation/Sinking Gold/Nickel Gold | OSP antioxidant/nickel plating, Shen Jin |

| Thermal Stress | 1 hour @ 350℃ | 3 x 10 Sec @ 280 ℃ | 15 min @ 350 ℃ | 3 x 10 Sec @ 280 ℃ |

Mechanical Equipment

HOME

HOME