How Much are the Electric Permittivity and Loss of Different Ceramic Materials?

Recently, one of our potential customers wanted to know how much the electric permittivity and loss of different ceramic materials are? This is a very common and important question, especially for engineers working with ceramic PCBs in high-frequency or high-power applications. In ceramic materials, this value varies depending on the composition and structure. It plays a major role in determining how signals move through the material, which is critical in PCB applications, especially at high frequencies. Today, let’s share what is electric permittivity and what is the loss of ceramic materials.

What is Electric Permittivity?

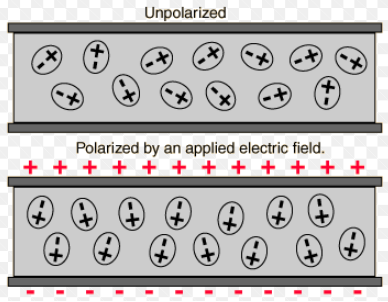

Electric permittivity, also known as the dielectric constant (εᵣ), describes how well a material can store electrical energy in an electric field. In simpler terms, it tells us how much a material can "hold" electric charge when voltage is applied. The higher the permittivity, the more charge the material can store. In ceramic materials, this value varies depending on the composition and structure. It plays a major role in determining how signals move through the material, which is critical in PCB applications, especially at high frequencies.

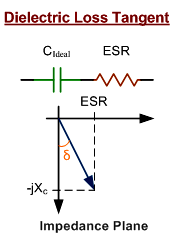

What is Loss Tangent?

Loss tangent, or dissipation factor (tan δ), measures how much electrical energy is lost as heat in a dielectric material. While permittivity measures energy storage, loss tangent measures energy loss. A low tan δ means the material is very efficient at insulating and doesn’t waste energy, which is important for keeping signal integrity and minimizing power loss. In ceramics, especially those used in high-frequency or high-power PCBs, a low loss tangent is preferred to reduce signal degradation and thermal issues.

Why Are Electric Permittivity and Loss Tangent Important in Ceramic PCBs?

In ceramic PCBs, both electric permittivity and loss tangent directly influence performance. The dielectric constant affects how fast signals travel through the board and how much the circuit can store and manage electrical energy. This becomes especially important in high-frequency applications like RF and microwave circuits. Meanwhile, the loss tangent determines how much signal quality is lost during transmission. A high loss leads to heat buildup and weaker signals, which is unacceptable in precision electronics. That’s why ceramic PCBs are typically made from materials with stable permittivity and extremely low loss tangent—offering reliability, speed, and thermal efficiency in compact designs.

Dielectric Properties of Common Ceramic Materials

|

Material |

Relative Permittivity (εᵣ) |

Loss Tangent (tan δ @ 1 MHz - 10 GHz) |

Notes / Applications |

|

Alumina (Al₂O₃) |

9.0 – 9.8 |

0.0001 – 0.0003 |

Most common; used in thick/thin film circuits |

|

Aluminum Nitride (AlN) |

8.5 – 9.0 |

0.0001 – 0.0002 |

High thermal conductivity |

|

Beryllium Oxide (BeO) |

6.5 – 7.5 |

0.0001 – 0.0003 |

Excellent thermal; toxic in powder form |

|

Silicon Nitride (Si₃N₄) |

7.5 – 8.5 |

0.0003 – 0.0005 |

High mechanical strength |

|

Zirconia (ZrO₂) |

20 – 40 |

0.001 – 0.01 |

High εᵣ but higher loss |

|

Titania (TiO₂) |

40 – 100+ |

0.0003 – 0.01 |

High permittivity ceramics |

|

Magnesium Titanate (MgTiO₃) |

16 – 18 |

0.0002 – 0.001 |

Microwave dielectric, stable at high frequency |

|

Barium Titanate (BaTiO₃) |

100 – 6000+ |

0.01 – 0.1 |

Ferroelectric, used in capacitors and multilayer ceramics |

|

Steatite |

5.8 – 6.5 |

0.0002 – 0.0005 |

Low-cost RF/microwave substrate |

|

Cordierite |

4.5 – 5.0 |

0.0001 – 0.0005 |

Very low CTE, good thermal stability |

⚠️ Important Considerations:

- Frequency dependence: εᵣ and tan δ can vary significantly with frequency. The values above are general and approximate at RF/microwave range (1 MHz – 10 GHz).

- Processing and porosity: Dielectric properties can vary based on the ceramic's density, sintering quality, and grain size.

- Temperature effects: Many ceramics show changes in εᵣ and tan δ with temperature. Materials like AlN and alumina are relatively stable, while ferroelectrics like BaTiO₃ can vary widely.

- Loss Tangent (tan δ) is often extremely low for microwave ceramics (<0.001) to minimize power loss in high-frequency circuits.

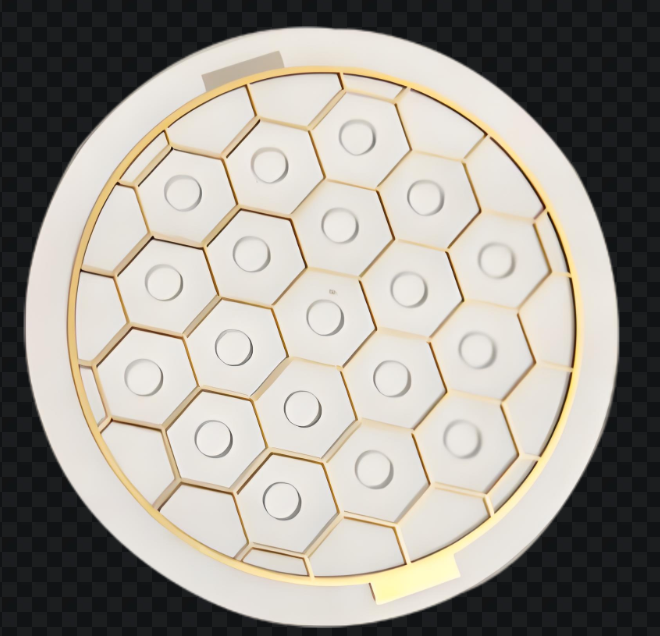

Best Technology – Your Reliable Ceramic PCB Manufacturer

Best Technology is a professional PCB manufacturer based in China, specializing in high-performance ceramic PCBs and advanced electronic substrate solutions. Since our founding, we’ve been committed to delivering premium quality, precision-engineered products for industries that demand reliability — including medical, aerospace, automotive, LED, RF, and power electronics. Why engineers trust Best Technology:

- Specialized in Ceramic PCBs: From alumina and aluminum nitride to BeO and Si₃N₄, we offer a wide range of ceramic materials tailored for thermal management and high-frequency applications.

- Full Traceability: Using MES systems, we ensure every board is traceable, from raw materials to shipment.

- One-Stop Service: We provide end-to-end support — from PCB design, ceramic substrate fabrication, to component assembly and testing.

- Advanced Equipment: With precision laser cutting, thick/thin film processing, and vacuum reflow ovens, we manufacture boards that meet tight tolerances and complex demands.

- Fast Turnaround & Global Support: Our engineering and sales teams offer prompt response and flexible lead times to meet your schedule.

- Certifications: ISO9001, IATF16949, ISO13485, AS9100D

Whether you need custom ceramic PCBs, high-frequency substrates, or hybrid PCB assemblies, Best Technology has the expertise and infrastructure to meet your technical and commercial requirements. Let us be your most trusted partner in ceramic PCB solutions!

HOME

HOME