Cutting Alumina: How to Cut Alumina Substrate? | BST CeramicPCB

Alumina (aluminum oxide) is a superstar in advanced ceramics, prized for its hardness, heat resistance, and durability. But how to cutting or machining it? That’s where things get tricky. Whether you’re working on electronics, medical devices, or industrial components, here’s everything you need to know about handling alumina safely and effectively.

Is alumina machinable?

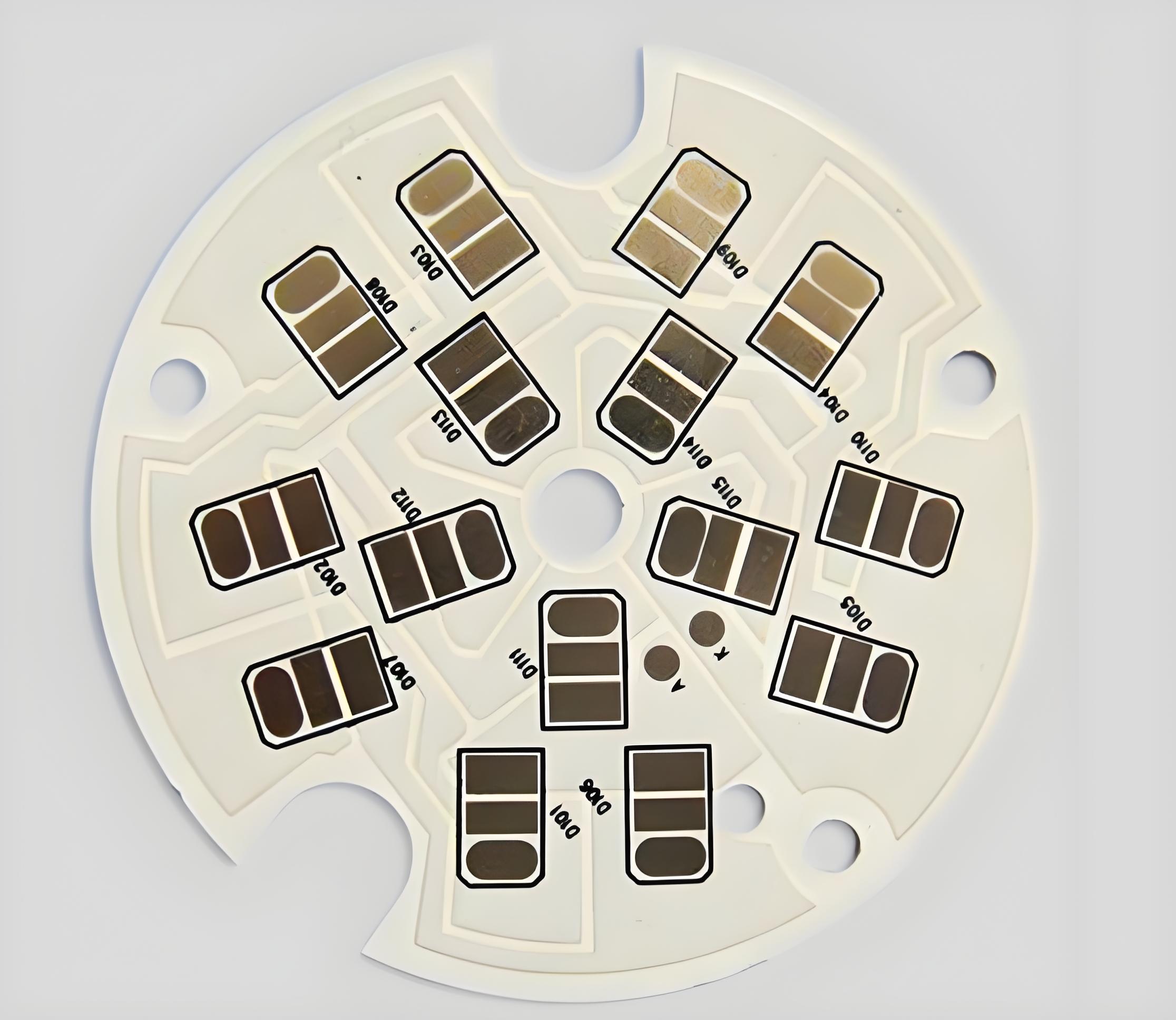

Alumina, also known as aluminum oxide, is a high-performance ceramic widely used in electronics, aerospace, and medical applications. It's known for its hardness, thermal stability, and corrosion resistance. But when it comes to machining, it's not as straightforward as metal or plastic.

So, is alumina machinable? Technically, Yes, alumina can be machined—but not like metal or plastic. Alumina is technically machinable, but its extreme hardness (9 on the Mohs scale) and brittleness demand caution. This hardness makes it resistant to wear, but also difficult to machine using traditional tools. Machining alumina requires diamond-coated tools or laser cutting systems. Standard drills or saw blades simply won’t work—they’ll wear out almost instantly or crack the material.

Pro Tip: Alumina grades matter! High-purity (99.5%+) alumina is harder but more brittle. Lower purity (96%) variants are slightly easier to machine.

How do you cut alumina ceramic?

Cutting alumina ceramic takes more than just steady hands. It demands the right equipment and a clear understanding of the material’s behavior under stress. There are two ways that manufacturers to cut the alumina ceramic substrate:

- Diamond Blades

- Use a precision wet saw or dicing saw with a diamond-coated blade.

- Coolant is a must to reduce heat and debris.

- Ideal for thick substrates or straight cuts.

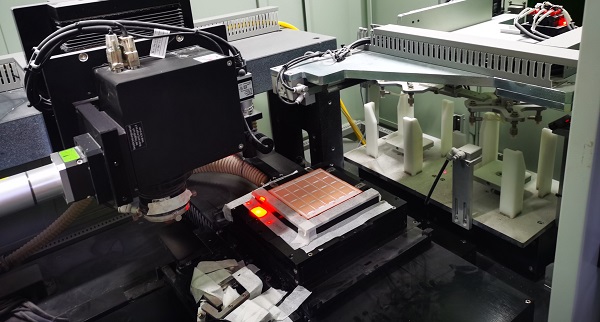

- Laser Cutting (Commonly used)

- CO₂ or UV lasers create clean, precise edges.

- Best for thin sheets (<0.5mm) and complex shapes.

- Minimizes physical contact (and cracking risk).

How do you cut ceramic without breaking it?

Ceramics, especially technical ones like alumina, don’t flex like metals. They shatter. To cut them without breaking, control is everything.

- Stabilize the Material: Secure the ceramic firmly with clamps or adhesives.

- Low Feed Rates: Move tools slowly to limit stress buildup.

- Minimize Vibration: Use rigid machinery or damping systems.

- Pre-Score Surfaces: Create a shallow guide groove to control the cut path.

Considerations before cutting alumina substrate

Before you touch the material, understand what you're working with. Alumina substrates vary in thickness, grain structure, and purity. Each of these affects how it reacts to cutting.

- Know your grade. 96% alumina behaves differently than 99.6% or higher purity types. Higher purity generally means more brittleness. That’s important when planning your cut.

- Confirm the thickness. Thinner substrates are more delicate and may need laser over mechanical cutting. If you’re dealing with large-format sheets, secure them to prevent flexing during the process.

- Clean ceramic substrate surface. Any dust or debris on the surface can interfere with blade contact and create uneven cuts. Clean the surface before beginning.

- Last, think about post-cut processing. Will you need to grind, polish, or mount the alumina? That affects how clean the cut needs to be. Planning ahead saves time and reduces material loss.

Is alumina the same as aluminum?

It’s a common mix-up, but alumina and aluminum are not the same thing.

Alumina (Al₂O₃) is a compound made from aluminum and oxygen, and it is a ceramic material. It’s a white, hard ceramic that’s stable, non-conductive, and used in electronics, aerospace, and biomedical tools.

Aluminum, on the other hand, is a lightweight metal. It’s conductive, malleable, and widely used in everything from soda cans to aircraft parts.

How do you reduce alumina to aluminum?

Reducing alumina to aluminum is no small feat. It requires extreme conditions and is done through a process called electrolytic reduction, specifically the Hall–Héroult process.

1. Dissolve Alumina: Mix Al₂O₃ with molten cryolite (Na₃AlF₆) at 950°C.

2. Electrolysis: A carbon anode and cathode split alumina into molten aluminum (collects at the bottom) and CO₂.

3. Energy Cost: This process uses ~15 kWh per kg of aluminum—a key reason recycling aluminum is eco-friendly.

Note: DIY reduction is impractical due to extreme temperatures and toxic byproducts.

How long does alumina last?

One of alumina’s greatest strengths is its lifespan. In most environments, it can last decades. Its chemical stability means it doesn’t corrode, oxidize, or degrade under normal conditions. It can withstand acids, bases, and high temperatures without losing structural integrity.

In electronics, alumina substrates maintain performance across thousands of thermal cycles. In medical implants, they resist wear better than many metals. Even in abrasive environments, alumina holds its shape longer than most materials.

Unless subjected to physical shock or misused, alumina rarely fails. It’s one of the reasons it’s used in demanding applications like cutting tools, missile nose cones, and semiconductor packaging.

Can you drill alumina ceramic?

Yes, but it’s not simple. Drilling alumina takes specialized tools and careful technique. You can't just grab a regular drill and start boring holes. It won’t work—and it might crack the part.

Use diamond-coated drill bits. They grind rather than cut. Also, low RPMs are key. High-speed drilling causes friction and heat, which increases the risk of cracks. Always use coolant to keep temperatures down. For very small or precise holes, laser drilling or ultrasonic machining is preferred. These methods use focused energy or vibration to create holes with minimal mechanical stress.

Remember: never force the drill. Let the bit do the work. Proper setup avoids costly breakage and wasted time.

Why is alumina so hard?

The high hardness of aluminum oxide is mainly attributed to the characteristics of its crystal structure and chemical bonds.

From the perspective of crystal structure, alumina usually exists in the form of corundum, and its crystal structure is compact and highly symmetrical. In the crystal, aluminum ions (Al³⁺) and oxygen ions (O²⁻) are closely bound together through ionic bonds. Ionic bonds have strong directionality and saturation. The electrostatic attraction between ions makes them closely stacked and difficult to be easily broken by external forces, so that alumina has high hardness.

In addition, the hardness of alumina is also related to its chemical stability. Alumina is a very stable compound and is not prone to chemical reactions with other substances. For instance, under harsh conditions such as high temperature and high pressure, alumina can still maintain its hard properties and is not easily worn or deformed.

If you're looking for a trusted partner to supply or process alumina substrates, Best Technology is here to help. Our team uses advanced cutting and drilling techniques to deliver clean, precise results—whether for electronic circuits, medical devices, or industrial applications. We’re certified to ISO9001, ISO13485, and IATF16949 standards, ensuring top-notch quality. Our engineers work closely with you to ensure every cut, drill, and polish meets your expectations.

Want a quote or need technical advice? Contact Best Technology and let’s bring your next ceramic project to life—precisely, reliably, and professionally.

FAQs

1. What tools are best for cutting alumina?

Diamond saws and laser cutters are best. They offer precision without damaging the material.

2. Can I use a Dremel to cut alumina?

Not ideal. Dremels aren’t stable enough. You risk cracks and rough edges.

3. What’s the best thickness for easy cutting?

Substrates under 0.5mm are easier to laser cut. Thicker ones may need mechanical sawing.

4. Is alumina better than zirconia for electronics?

Alumina is more common and cost-effective. Zirconia is tougher but pricier.

5. Does alumina conduct electricity?

No, it’s an excellent insulator—perfect for high-voltage applications.

HOME

HOME