What is Silicon Nitride Dielectric Constant? Si3N4 Material Properties

The dielectric constant of silicon nitride (Si₃N₄) varies under different conditions. Most studies show that its dielectric constant is between 7 and 9. For thin film materials, it is about 6 to 9, and for bulk ceramics, it is 8.3 to 9.5.

What Is Dielectric Constant?

The dielectric constant, also known as relative permittivity, measures how much a material can store electrical energy in an electric field. It compares the material's ability to that of a vacuum. A higher dielectric constant usually means better capacitance, but the context matters. In RF circuits, for example, a lower and stable dielectric constant is more valuable.

In electronics, the dielectric constant determines impedance, signal propagation speed, and electromagnetic compatibility. Materials with predictable and stable dielectric constants allow for more accurate PCB designs, especially at high frequencies.

What Is the Dielectric Constant of Silicon Nitride (Si₃N₄)?

Silicon nitride generally has a dielectric constant between 7.0 and 9.0. This value can slightly vary depending on how the material is processed. For example, low-pressure chemical vapor deposition (LPCVD) Si₃N₄ tends to stay within that range. The dielectric loss tangent (tanδ) is usually low, often below 0.002 at 1 MHz. That low loss makes it a good fit for RF and microwave circuits.

Some measurements show variations at different frequencies. At lower frequencies like 1 kHz or 1 MHz, the dielectric constant remains steady. At GHz levels, slight decreases may occur, but the variation is minimal compared to many other ceramics. This frequency stability is one of Si₃N₄'s major advantages.

Si₃N₄ Material Properties

Silicon nitride isn't just known for its dielectric constant. It comes with a rich set of physical and mechanical properties that make it suitable for tough environments.

|

Property |

Value/Range |

|

Dielectric constant |

7.0 – 9.0 |

|

Density (g/cm3) |

3.1 |

|

Thermal conductivity |

20 – 90 W/m·K |

|

Density (g/cm3) |

3.1 |

|

Electrical resistivity |

>10¹⁴ Ω·cm |

|

Flexural strength |

~600 MPa |

|

Fracture toughness |

6–10 MPa·m¹/² |

|

Thermal expansion |

~3.2 x10⁻⁶ /K |

|

Refractive Index |

2.05 |

|

Infrared Absorption Band (µm) |

11.5-12.0 |

|

Energy Gap at 300K (eV) |

approx. 5.0 |

|

DC Resistivity at 25 C (ohm-cm) |

approx. 10^14 |

|

DC Resistivity at 500C (ohm-cm) |

2 x 10^13 |

|

Etch Rate in Buffered HF (angstroms/min) |

5-10 |

These properties explain why Si₃N₄ is favored in aerospace, power electronics, and automotive electronics. It holds up under heat, pressure, and vibration. You can use it for more than just circuit substrates.

Factors That Affect the Dielectric Constant of Silicon Nitride (Si₃N₄)

The dielectric constant of silicon nitride can change depending on several things.

1. Deposition Method: Silicon nitride can be made using different methods, like LPCVD or PECVD. These methods affect the material's thickness, density, and purity, which can change how well it stores electrical energy.

2. Density and Air Bubbles (Porosity): If the material has tiny air pockets inside it, it won’t hold as much electric charge. Denser materials without these gaps usually have a higher dielectric constant.

3. Impurities or Dopants: Sometimes, other atoms get mixed in during production—like oxygen or extra nitrogen. These can affect how electricity moves through the material.

4. Frequency of the Electric Signal: Silicon nitride keeps its dielectric constant steady when the electric signal moves at normal or high speeds (even at GHz levels). It may drop just a little at very high frequencies.

5. Temperature: Unlike some materials, silicon nitride keeps working well even when temperatures change a lot. That makes it useful in electronics that need to work in hot or cold places.

Comparison: Silicon Nitride vs Other Ceramic Materials

Understanding how Si₃N₄ compares to other ceramic substrates helps in material selection.

|

Material |

Dielectric Constant |

Thermal Conductivity |

Best For |

|

Si₃N₄ |

7.5–8.5 |

20–90 W/m·K |

Strength + Insulation + RF |

|

AlN |

~8.6 |

170–200 W/m·K |

High-frequency + Thermal Mgmt |

|

Alumina (Al₂O₃) |

~9.5 |

24 W/m·K |

General purpose electronics |

|

BeO |

~6.7 |

~250 W/m·K |

Extreme thermal needs |

Silicon nitride maintains a balance. It's not the most thermally conductive, but it adds mechanical toughness and dielectric reliability. That mix is hard to beat for certain applications.

How Silicon Nitride Performs in High-Frequency and High-Voltage Applications?

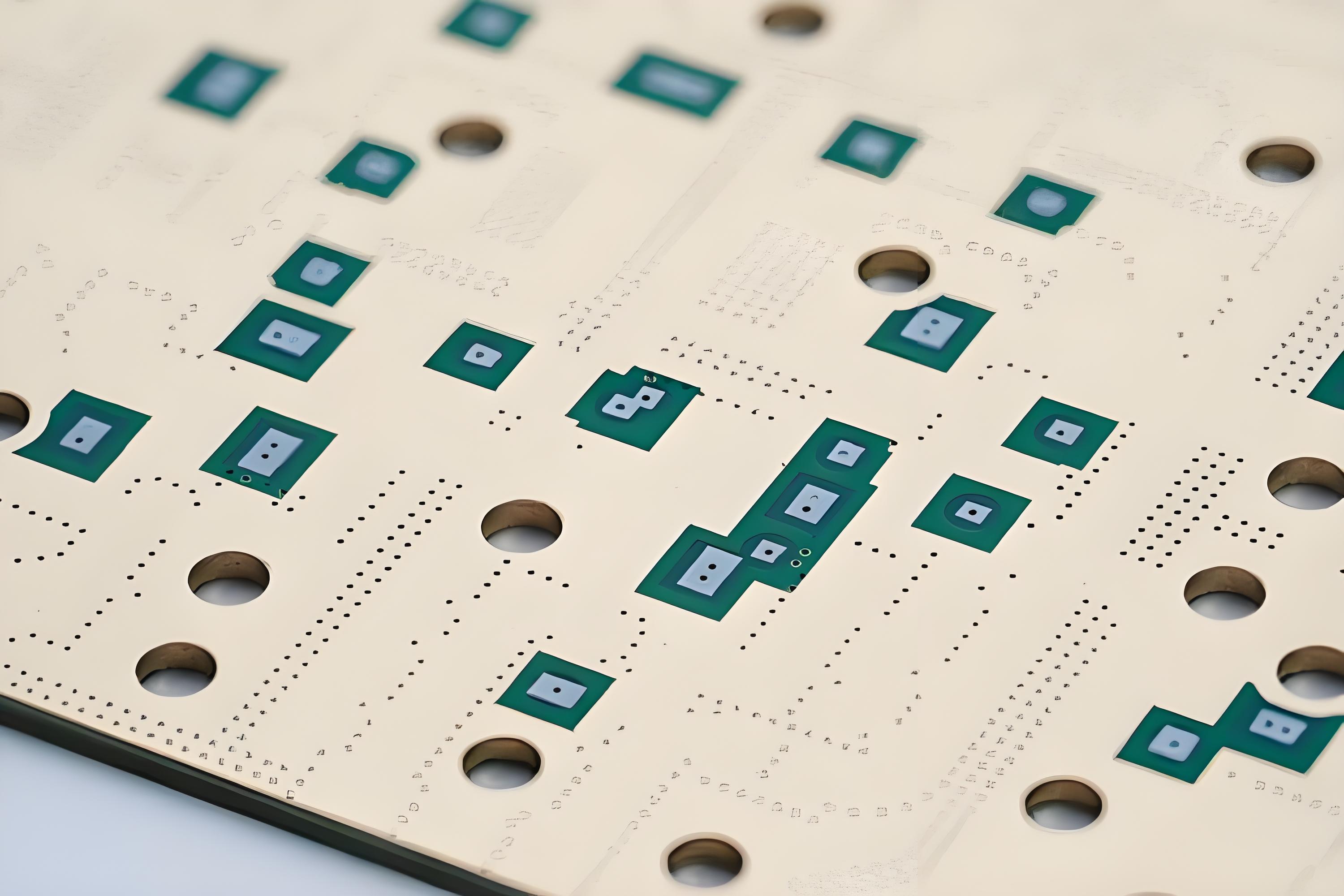

In high-frequency systems, signal integrity is everything. Any fluctuation in dielectric constant affects impedance and timing. Silicon nitride gives designers peace of mind with its stability. It’s used in RF filters, antenna packages, and radar modules. Especially in 5G and mmWave, where performance depends on predictable dielectric behavior.

In high-voltage modules, Si₃N₄’s high dielectric strength and thermal stability come into play. It acts as both a mechanical and electrical insulator. That’s why it shows up in power converters and IGBT modules. It also helps with EMI suppression and isolation in mixed-signal environments. Engineers trust its consistency under harsh electrical stress.

Is Silicon Nitride Right for Your Application?

Choosing Si₃N₄ depends on your needs. If you want high thermal conductivity and simple handling, AlN might be better. But if you need mechanical durability, low dielectric loss, and stable properties, Si₃N₄ is often a better pick.

It’s also more forgiving in high-shock or vibration settings. Aerospace, EVs, and telecom often go with Si₃N₄ when durability matters. It works well in multi-layer structures and hybrid assemblies.

Where to Source High-Quality Silicon Nitride Substrates?

Best Technology offers custom ceramic substrates, including silicon nitride, alumina substrate and aluminum nitride. We support engineers in RF, power, and automotive fields with tailored solutions.

Our services include:

- Precise dimensional control

- Custom circuit patterns (Cu, Ag, Au, etc.)

- Thick film, thin film, DPC, DBC, HTCC, LTCC, AMB technology

- Laser-cutting, Co2 cutting, and multilayer stacking

We are certified with ISO9001, ISO13485, IATF16949, and AS9100D. Our MES system tracks every process step, so you can trust our quality.

If you're working on a project needing high-performance substrates, contact us. We can provide samples and engineering support for your next design.

5 FAQs about Silicon Nitride

1. What is the typical dielectric constant of silicon nitride?

It usually ranges from 7.5 to 8.5 depending on density and processing methods.

2. How does frequency affect silicon nitride’s dielectric properties?

At frequencies up to several GHz, Si₃N₄ maintains a stable dielectric constant with minimal loss.

3. Is silicon nitride better than alumina or AlN for RF designs?

It depends on your priorities. Si₃N₄ offers mechanical toughness and good dielectric performance, while AlN provides better thermal conductivity.

4. Can Si₃N₄ be used for multilayer ceramic PCBs?

Yes. Its strength and stability make it suitable for multilayer circuits, especially under thermal or mechanical stress.

5. What thickness and tolerance can be achieved with Si₃N₄ substrates?

Best Technology offers thicknesses from 0.25 mm to 3 mm with tight tolerances, depending on the project requirement.

Conclusion

Silicon nitride offers more than just a decent dielectric constant. It provides a full suite of physical, thermal, and electrical benefits. When you need consistent performance in demanding environments, it’s a material worth serious consideration.

Its reliability in high-frequency and high-voltage systems makes it a top choice across industries. If you need materials that can handle complexity and stress, Si₃N₄ deserves a place in your shortlist.

HOME

HOME