Ceramic PCB in Stage Lighting: Why It is Better Than FR4 PCB?

Ceramic PCB has become a game-changer in stage lighting, offering unmatched performance in heat management, reliability, and durability. In professional lighting systems—whether in theaters, concerts, or live shows—the demand for brighter, more reliable fixtures continues to rise. Traditional FR-4 boards are no longer enough to meet these expectations. Today, ceramic PCBs provide the backbone for advanced lighting solutions, enabling engineers to design powerful systems without sacrificing stability.

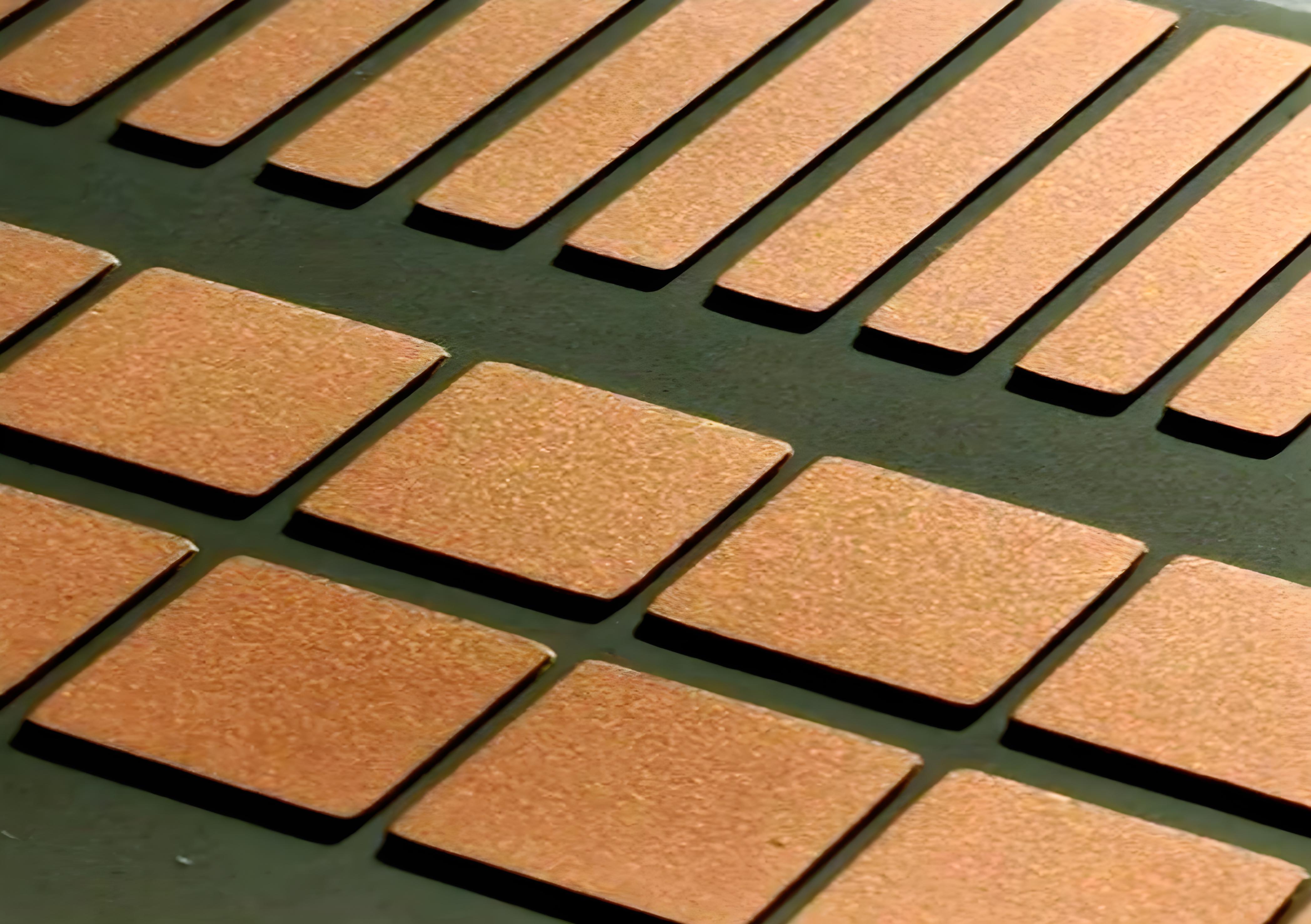

At Best Technology, a trusted ceramic PCB manufacturer certified with ISO9001, ISO13485, IATF16949, and AS9100D, we provide top-quality ceramic substrates, including Alumina PCB and Aluminum Nitride PCB, tailored for high-performance stage lighting applications.

What are the Challenges of Modern Stage Lighting?

Modern stage lighting combines high brightness, compact design, and long operating hours. These requirements create several challenges for the internal PCB:

- Heat generation: High-power LEDs and laser diodes convert much of their input into heat rather than light.

- Miniaturization: Compact housings demand densely packed circuits, creating hot spots.

- Reliability: Lighting failure during a live performance is unacceptable.

- Performance degradation: LED brightness decreases as junction temperature rises, leading to uneven light quality.

Traditional FR-4 materials, with a thermal conductivity of only 0.3 W/mK, trap heat and accelerate PCB failure. This is where ceramic PCB for stage lighting takes center stage.

Why is Ceramic PCB Superior to FR-4 in Stage Lighting?

1. Outstanding Thermal Conductivity

Alumina PCB offers 20–30 W/mK, while Aluminum Nitride PCB reaches 150–180 W/mK. Compared to FR-4, this means ceramic substrates quickly dissipate heat, preventing LEDs from overheating and preserving brightness.

2. Better Thermal Expansion Matching

Ceramic PCB substrates align more closely with the thermal expansion rates of silicon chips. This reduces mechanical stress, minimizing solder joint cracks in moving head lights and vibration-heavy environments.

3. High Electrical Insulation

Ceramic PCBs act as excellent insulators, supporting high voltages safely. This is essential for LED arrays and driver circuits used in stage lighting.

4. Mechanical Strength and Chemical Stability

Ceramic substrate PCB is rigid, corrosion-resistant, and stable under extreme conditions. It does not warp under heat, ensuring consistent performance in challenging environments.

How is Ceramic PCB Applied in Stage Lighting?

The adoption of ceramic PCBs has expanded into multiple areas of stage lighting:

- High-power LED modules: Ceramic PCBs keep LED junctions cool, extending lifespan and maintaining brightness.

- Laser diode drivers: Aluminum nitride PCB ensures thermal stability for sensitive laser diodes.

- Driver and control circuits: Dense circuits in compact lighting fixtures benefit from better heat dissipation.

- UV lighting systems: Ceramic substrate PCB resists UV degradation, ideal for special-effect lights.

These applications show why ceramic PCB for stage lighting has become indispensable.

What are the Business Benefits of Ceramic PCB in Lighting?

While the ceramic PCB cost is higher than FR-4, the long-term savings are substantial:

- Lower failure rates: Better reliability reduces warranty claims and downtime.

- Simplified cooling systems: Improved onboard heat dissipation reduces the need for bulky fans and heat sinks.

- Enhanced brand value: Manufacturers deliver longer-lasting, brighter lights, boosting their reputation.

This proves ceramic PCBs are not just a technical choice but also a smart business decision.

Ceramic PCB vs FR-4: Which is Better for Stage Lighting?

|

Feature |

Ceramic PCB |

FR-4 PCB |

|---|---|---|

|

Thermal Conductivity |

20–180 W/mK |

0.3 W/mK |

|

Reliability |

High under heat & vibration |

Lower under stress |

|

Cost |

Higher upfront |

Lower |

|

Lifespan |

Longer |

Shorter |

|

Applications |

High-power LED, laser drivers, UV lighting |

Low- to mid-power circuits |

For demanding environments like stage lighting, ceramic clearly outperforms FR-4 PCB.

Why Choose Best Technology as Your Ceramic PCB Manufacturer?

At Best Technology, we specialize in ceramic PCB manufacturing with Alumina PCB, Aluminum Nitride PCB, and other advanced substrates. Our strengths include:

- Certifications: ISO9001, ISO13485 (medical), IATF16949 (automotive), AS9100D (aerospace).

- Quality assurance: Rigorous testing and MES system traceability.

- Competitive pricing: Cost-effective solutions without compromising quality.

- Professional engineering support: Helping you optimize your stage lighting designs.

Whether you need high power LED ceramic PCB or custom ceramic substrate PCB, our team delivers reliable and durable solutions for your projects.

FAQs

1. What is the main advantage of ceramic PCB for stage lighting?

Its superior thermal conductivity prevents LED overheating, extending lifespan and brightness.

2. Is aluminum nitride PCB better than alumina PCB?

Yes, Aluminum Nitride PCB offers higher thermal conductivity, but Alumina PCB is more cost-effective.

3. How does ceramic PCB compare to FR-4 PCB?

Ceramic PCB handles heat and vibration much better, making it ideal for demanding applications like stage lighting.

4. Does ceramic PCB cost more than FR-4?

Yes, but the total cost of ownership is lower due to reduced failures and longer product lifespan.

5. Can ceramic PCBs be customized for unique lighting designs?

Absolutely. Best Technology provides customized ceramic PCBs to match your lighting requirements.

HOME

HOME