What are Different Grades of Alumina? Alumina Ceramic Composition

When it comes to high-performance ceramics, alumina stands out for its wide range of industrial applications. From electronic substrates to wear-resistant parts, alumina is everywhere—but not all alumina is the same. There are different grades of alumina, and each grade has specific properties suited for certain tasks. Whether you're working with ceramic PCBs or considering materials for filtration, understanding alumina grades helps you choose the right material for your needs.

What Is Alumina and Why Do Grades Matter?

Alumina, or aluminum oxide (Al₂O₃), is a ceramic material known for its hardness, stability, and insulating properties. It's commonly used in electronics, mechanical parts, and even medical devices. But its performance depends on its grade, which is essentially a measure of purity and composition.

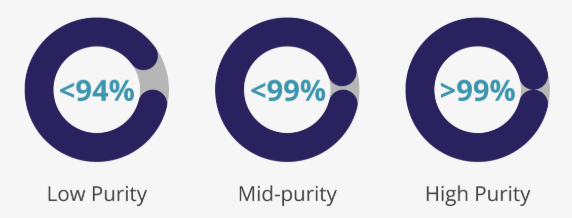

The term "alumina grades" refers to the varying purity levels and the presence of other elements in the ceramic. Higher purity alumina typically means better thermal, electrical, and mechanical properties. Lower purity grades may contain additional oxides that affect the ceramic’s characteristics.

What Are the Different Grades of Alumina?

Alumina grades are usually categorized by purity level. The higher the percentage of Al₂O₃, the fewer impurities are present. These impurities could include silica (SiO₂), magnesia (MgO), iron oxide (Fe₂O₃), or calcium oxide (CaO), which can alter the ceramic’s performance. The most common alumina grades are including:

- 85% Alumina (Low Purity)

This is considered a low-grade alumina. It contains a large amount of impurities and is used in general structural applications where high performance isn’t required. It’s more affordable but lacks the electrical and thermal properties needed for advanced applications.

- 95% Alumina (Standard Grade)

At this level, alumina offers better wear resistance and mechanical strength. It is commonly used for components like tubes, insulators, and grinding media.

- 96% Alumina

This is one of the most popular grades for ceramic PCBs. It has a good balance of thermal conductivity, dielectric strength, and affordability. This is most commonly used and it’s a go-to material for LED lighting, power modules, and consumer electronics.

- 99% Alumina

A step up in purity, 99% alumina is used in applications where better corrosion resistance and thermal stability are required. It’s also more consistent in dielectric behavior, making it suitable for higher-performance electronics.

- 99.5% – 99.8% Alumina

At this level, alumina provides excellent electrical insulation, higher strength, and improved thermal performance. It’s often used in semiconductor packaging, medical implants, and advanced electronic devices.

- 99.9%+ Alumina (High Purity Alumina, HPA)

Often referred to as HPA, this grade is essential in high-tech fields like LED production, optical lenses, and semiconductor wafers. With minimal impurities, it delivers unmatched chemical stability and purity. Grades can go up to 99.99% (4N) or 99.999% (5N), depending on the application.

What Is the Standard of High Purity Alumina?

There’s no single global standard for high purity alumina (HPA), but generally, 99.9% purity or higher qualifies. In electronic applications, HPA ensures better thermal management and electrical insulation, especially important for ceramic PCBs or optical components. The higher the purity, the lower the risk of contamination or material degradation during use.

Standards often depend on industry:

- Electronics: ≥99.6% purity is typical for alumina ceramic substrates.

- Optics and semiconductors: Often require 99.99% or higher.

- Medical devices: Also demand high purity to prevent biological contamination.

Certification from suppliers usually includes a Certificate of Analysis (COA), which outlines the exact purity level and trace element content.

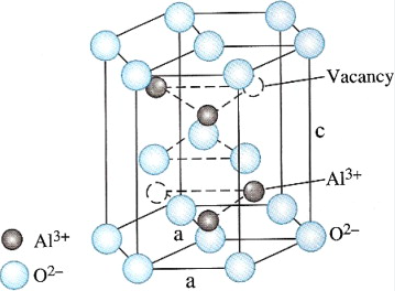

Alumina Ceramic Composition & Structure

At its core, alumina ceramic consists of aluminum oxide. However, to modify properties or ease manufacturing, other elements may be added. Here’s a basic breakdown:

- Al₂O₃ (Alumina): The primary component, providing hardness, electrical insulation, and thermal stability.

- SiO₂ (Silica): Sometimes present in lower grades; affects sintering and reduces purity.

- MgO (Magnesia): Can be added to aid in sintering and improve grain structure.

- ZrO₂ (Zirconia): Adds toughness but may reduce electrical properties.

- CaO (Calcium oxide) and Fe₂O₃ (Iron oxide): Usually impurities; high levels are undesirable.

For ceramic PCBs, a composition of 96–99.6% Al₂O₃ is typical, balancing performance and cost. Higher purities ensure better dielectric strength and thermal conductivity, essential in high-density circuit designs. Aluminua substrate show as below:

Alumina Ceramic PCB Properties

|

Property |

Description |

|

Thermal Conductivity |

18–30 W/m·K (depends on alumina grade; higher purity provides better heat dissipation) |

|

Dielectric Strength |

≥15 kV/mm |

|

Volume Resistivity |

>10¹⁴ Ω·cm |

|

Coefficient of Thermal Expansion (CTE) |

~7–8 ppm/°C |

|

Operating Temperature |

Up to 1500°C |

|

Flexural Strength |

300–400 MPa |

|

Hardness (Mohs scale) |

9 |

|

Chemical Resistance |

Inert to most chemicals, acids, and alkalis |

|

Moisture Absorption |

0% |

|

Surface Finish Options |

Polished, lapped, or metallized (based on application and assembly needs) |

|

Typical Thickness |

0.25 mm to 1.5 mm (customizable depending on design) |

How to Check Aluminum Purity?

If you're sourcing alumina ceramic components, knowing the purity level is essential. Here are standard methods to check it:

1. X-Ray Fluorescence (XRF)

This method analyzes elemental composition quickly and non-destructively. It’s commonly used in manufacturing for quality control.

2. Inductively Coupled Plasma (ICP) Analysis

This is a high-precision method that measures trace elements down to parts per million (ppm). It’s ideal for confirming high purity alumina grades.

3. Loss on Ignition (LOI)

This measures weight loss after heating, which can indicate impurities like water or organic matter.

4. Supplier Certification

Reputable suppliers provide COAs showing exact alumina purity and composition. Always request these documents, especially for critical applications.

For ceramic PCBs, verifying that you’re receiving 96% or 99.6% alumina is important for consistent thermal and electrical performance.

Alumina Ceramic Uses

- Electronic substrates: Used in ceramic PCBs for thermal and electrical stability.

- Wear-resistant parts: Like seals, valves, and bearings.

- Medical components: Dental implants, prosthetics, and surgical tools.

- Lighting and optics: In LEDs, laser tubes, and lenses.

- Chemical industry: Linings for reactors and pipes due to corrosion resistance.

What Are the Differences Between Alumina and Activated Alumina?

While they share the same chemical base, alumina ceramics and activated alumina are used for very different purposes.

|

Feature |

Alumina Ceramic |

Activated Alumina |

|

Structure |

Dense, solid material |

Porous, granular |

|

Main Use |

Structural/electronic parts |

Adsorption/filtration |

|

Surface Area |

Low |

Very high |

|

Thermal Stability |

Very high (up to 1500°C) |

Moderate |

|

Water Absorption |

Low |

High (due to porosity) |

|

Applications |

PCBs, insulators, medical parts |

Water purification, gas drying |

Activated alumina is commonly used to remove moisture and impurities from gases or liquids. It's found in desiccants, water filters, and air dryers. However, it is not used in ceramic PCBs or structural applications due to its porous and brittle nature.

Why Choose Best Technology for Alumina Ceramic PCBs?

At Best Technology, we specialize in producing high-quality alumina ceramic PCBs. We offer:

- Full Turnkey Service: From ceramic PCB design to ceramic PCB assembly.

- Material Options: From 96% to 99.6% alumina grades, based on your application needs.

- Certifications: We are ISO9001, ISO13485, IATF16949, and AS9100D certified, compliance with medical, automotive, and aerospace standards.

- Engineering Support: Our team helps you select the right alumina grade, design for manufacturability, and reduce lead times.

- Global Service: We deliver custom solutions worldwide, with reliable communication and competitive pricing.

Whether you need prototypes or large-scale production, we can provide the right alumina grade for your application.

FAQs

1. What alumina grade is best for ceramic PCBs?

Typically, 96% alumina is ideal for standard PCB needs. For high-performance applications, 99.6% alumina may be used.

2. Is higher purity always better?

Not necessarily. Higher purity offers better properties but also increases cost. The key is to match alumina grade to your application needs.

3. Can alumina ceramics be customized?

Yes, we offer custom shapes, thicknesses, and surface finishes based on your design.

4. Is activated alumina suitable for electronics?

No, it’s used for adsorption and filtration, not for structural or electrical components.

5. How can I verify alumina grade from a supplier?

Request a Certificate of Analysis (COA) and use XRF or ICP testing for purity verification.

HOME

HOME