Why Can't Copper Be Used as a Conductor in Thick-Film Ceramic Substrates?

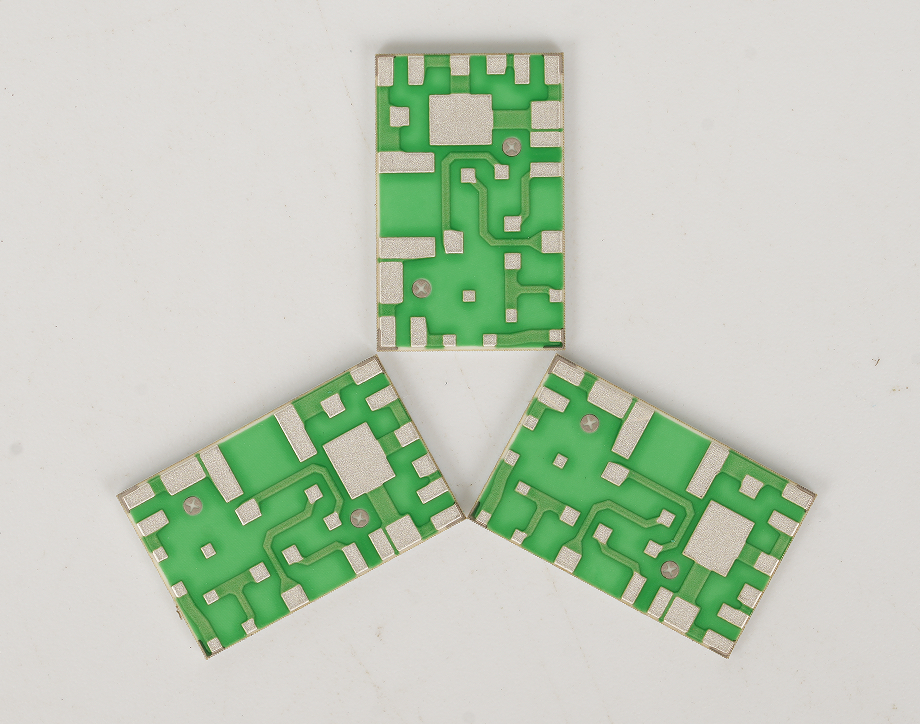

Thick-film ceramic substrates are widely used in high-power electronics, LED packaging, automotive modules, and aerospace applications due to their excellent thermal conductivity, electrical insulation, and mechanical stability. These substrates typically employ conductive traces made from precious metals like silver (Ag), gold (Au), or palladium-silver (Pd-Ag) alloys.

A natural question arises: Why not use copper (Cu), which has superior electrical conductivity and is far more cost-effective? The answer lies in material science challenges related to oxidation, sintering behavior, and compatibility with ceramic substrates. This article explores the technical limitations that prevent copper from being used in thick-film ceramic circuits and discusses alternative solutions.

Understanding Thick-Film Technology

Before diving into why copper is unsuitable, it’s essential to understand how thick-film circuits are manufactured:

- Paste Preparation: A conductive paste is formulated by mixing metal powders (e.g., Ag, Au), glass frits (for adhesion), and organic binders.

- Screen Printing: The paste is deposited onto a ceramic substrate (e.g., Al₂O₃, AlN) through a patterned screen.

- Drying & Firing: The printed substrate is dried and then fired at high temperatures (700–900°C) to burn off organics and sinter the metal particles into a solid conductor.

Copper, despite its excellent bulk conductivity (~1.68 μΩ·cm), faces multiple challenges in this process.

Key Challenges of Using Copper in Thick-Film Ceramics

2.1. Severe Oxidation at High Temperatures

Copper oxidizes rapidly when exposed to air at elevated temperatures:

- Below 300°C: Forms Cu₂O (cuprous oxide).

- Above 800°C: Forms CuO (cupric oxide), which is highly insulating.

Unlike silver or gold, which remain stable in air at firing temperatures, copper oxides degrade conductivity and weaken adhesion to ceramics. Even if fired in a nitrogen atmosphere, residual oxygen can still cause oxidation.

2.2. Poor Sintering Behavior

- High Melting Point (1085°C): Thick-film pastes must sinter below 900°C to avoid damaging the ceramic substrate. Copper does not sinter well at these temperatures, leading to porous, weak conductors.

- Lack of Glass Bonding: Conventional thick-film pastes use glass frits to improve adhesion. Copper does not bond well with these glasses, resulting in delamination.

2.3. Diffusion into Ceramics

At high temperatures, copper tends to diffuse into oxide ceramics (e.g., Al₂O₃), causing:

- Increased resistance due to copper loss.

- Potential contamination of the ceramic, affecting insulation properties.

2.4. Difficulty in Paste Formulation

- Oxidation in Storage: Copper powders in organic pastes slowly oxidize, reducing shelf life.

- Incompatible Organic Vehicles: Many thick-film pastes use solvents that can accelerate copper corrosion.

Comparison with Conventional Thick-Film Conductors

|

Property |

Copper (Cu) |

Silver (Ag) |

Gold (Au) |

Palladium-Silver (Pd-Ag) |

|---|---|---|---|---|

|

Resistivity (μΩ·cm) |

1.68 |

1.59 |

2.44 |

3–5 |

|

Oxidation Resistance |

Poor |

Moderate |

Excellent |

Excellent |

|

Sintering Temp. (°C) |

>900 |

600–850 |

600–850 |

700–900 |

|

Adhesion to Ceramics |

Weak |

Good |

Good |

Excellent |

|

Cost |

Low |

Medium |

High |

High |

As seen, silver and gold are far more stable during firing, while copper struggles with oxidation and adhesion.

Alternative Solutions for Copper on Ceramics

If copper must be used, alternative manufacturing methods exist—but they are not "thick-film" processes:

4.1. Direct Bonded Copper (DBC)

- A copper foil is bonded to ceramics (Al₂O₃/AlN) at high temperatures (1065°C) in a controlled atmosphere.

- Used in high-power modules (e.g., IGBTs).

4.2. Active Metal Brazing (AMB)

- Uses reactive brazing alloys (e.g., Ag-Cu-Ti) to bond copper to ceramics.

- Stronger than DBC but more expensive.

4.3. Thin-Film Deposition (Sputtering/Plating)

- Copper is deposited via vacuum sputtering and thickened by electroplating.

- Used in high-frequency circuits but not cost-effective for large substrates.

These methods avoid thick-film firing issues but are more complex and costly.

Future Prospects: Can Copper Ever Be Used in Thick-Film?

Research is ongoing to develop copper-compatible thick-film pastes, including:

- Low-Temperature Sintering Nano-Cu Inks: Nanoparticles sinter at <300°C, avoiding oxidation.

- Reducing Atmospheres: Firing in forming gas (N₂ + H₂) to prevent oxidation.

- Protective Coatings: Adding diffusion barriers (e.g., Ni, Sn) to prevent Cu migration.

However, none of these solutions have matched the reliability of traditional thick-film conductors yet.

Conclusion

Copper is unsuitable for conventional thick-film ceramic substrates due to:

✔ Oxidation at firing temperatures (forming insulating CuO).

✔ Poor sintering below 900°C, leading to weak conductors.

✔ Diffusion into ceramics, degrading performance.

✔ Difficulty in paste formulation and storage.

For now, silver, gold, and Pd-Ag alloys remain the standard due to their stability and reliability. While alternative copper-ceramic bonding methods (DBC, AMB) exist, they are not true thick-film processes. Future advancements in nano-copper inks or protective coatings may change this landscape, but for now, copper remains excluded from thick-film ceramic circuits.

The electronics industry constantly seeks cost-effective alternatives to precious metals. However, in thick-film ceramics, material stability and process compatibility outweigh cost savings. Until copper’s oxidation and sintering challenges are resolved, thick-film circuits will continue relying on silver and gold-based conductors.

Would you like a deeper dive into any specific aspect, such as copper nanoparticle pastes or DBC technology? Let me know in the comments!

HOME

HOME