DPC Ceramic PCB Materials: Surprising Science Inside

You encounter advanced materials when you explore dpc ceramic pcb technology. You find alumina, aluminum nitride, beryllium oxide, and copper as the core components. Each ceramic brings unique benefits. Alumina offers reliable electrical insulation and mechanical strength. Aluminum nitride delivers higher thermal conductivity, while beryllium oxide stands out for its exceptional heat transfer but requires careful handling for safety. Copper layers enhance electrical performance. The table below shows how thermal conductivity varies among these ceramic substrates:

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Beryllium Oxide (BeO) | 330 |

| Aluminum Nitride (AlN) | 170-200 |

| Alumina (Al₂O₃) | ~30 |

Selecting the right ceramic material shapes the performance and reliability of your pcb. You might find the science behind these choices more surprising than you expect.

Key Takeaways

- Choose the right ceramic material for your PCB to enhance performance. Alumina is cost-effective, aluminum nitride offers high thermal conductivity, and beryllium oxide excels in extreme conditions.

- Understand the direct copper bonding process. This method creates a strong connection between copper and ceramic, ensuring high reliability and performance in your PCB.

- Consider thermal conductivity when selecting materials. Higher thermal conductivity helps dissipate heat efficiently, which is crucial for high-power electronics.

- Evaluate electrical insulation properties. Strong insulation prevents short circuits and ensures safety in your PCB design.

- Match the ceramic substrate to your application needs. This approach guarantees reliable performance and longevity in demanding environments.

DPC Ceramic PCB Construction

Material Selection and Impact

You make critical choices when selecting materials for a dpc ceramic pcb. The ceramic substrate and copper layer shape the board’s electrical and thermal performance. Ceramic substrates, such as alumina, aluminum nitride, and beryllium oxide, offer high thermal conductivity and excellent dielectric strength. These properties set ceramic circuit boards apart from traditional organic substrates like FR4.

Ceramic substrates dissipate heat over 100 times faster than FR4. This feature is essential for high-power electronics.

The table below compares key properties of ceramic and organic substrates:

| Property | Ceramic Substrate | Organic Substrate (FR4) |

|---|---|---|

| Thermal Conductivity | High | Low |

| Dielectric Strength | Superior | Moderate |

| CTE Compatibility | Close to silicon | Higher mismatch |

| Mechanical Strength | High | Lower |

| Temperature Resistance | >1000°C | <300°C |

| Reliability | Excellent | Limited |

Ceramic substrates align closely with the coefficient of thermal expansion of silicon chips. This match reduces solder joint stress and improves reliability. You also benefit from structural stability at high temperatures, which is vital for advanced ceramic pcb manufacturing.

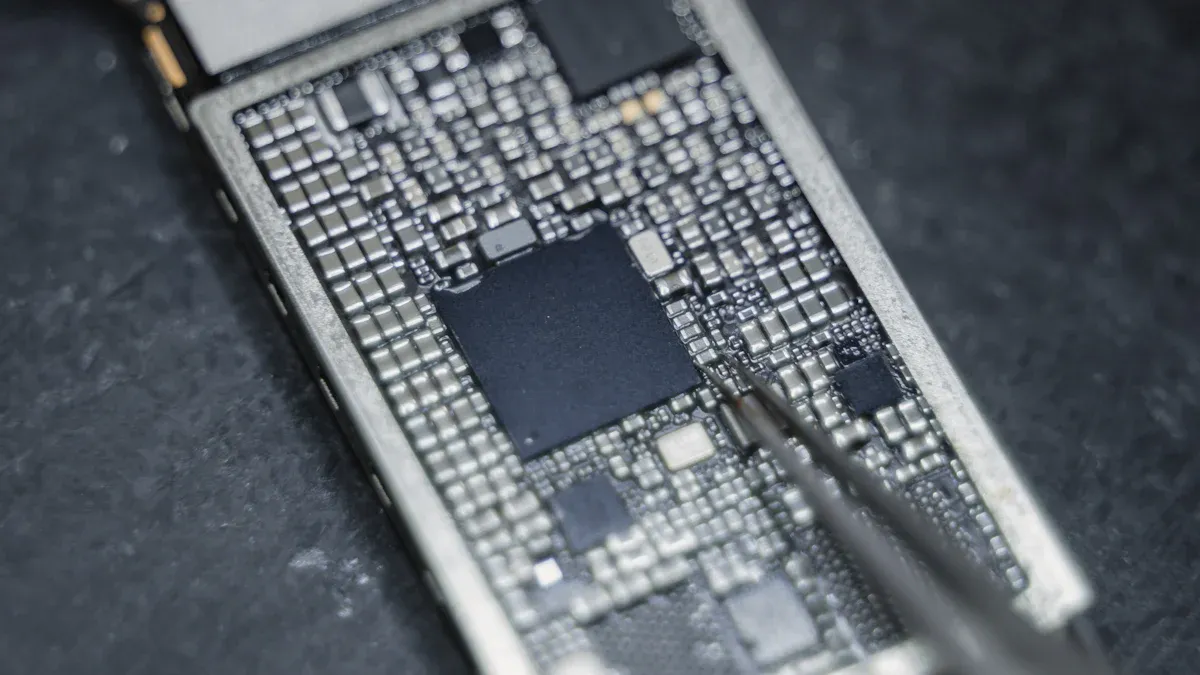

Direct Copper Bonding Process

The direct copper bonding process creates a strong connection between copper and ceramic. You start with ceramic substrate preparation, using laser cutting for precise sizing. Next, you laminate a thin copper foil onto the ceramic. High temperatures, usually between 1000°C and 1100°C, bond the copper to the ceramic substrate. Chemical etching removes excess copper, and drilling creates vias and mounting holes. You apply a solder mask and finish the surface before separating panels into individual boards.

Steps in Direct Copper Bonding:

- Ceramic substrate preparation

- Copper foil lamination

- High-temperature bonding

- Chemical etching

- Drilling for vias and mounting

- Solder mask and surface finishing

- Panel separation

Direct copper bonding offers several advantages over other metallization methods. You avoid hydrogen gas production, which can cause reliability issues. The process eliminates copper film interfaces, enhancing mechanical strength and uniformity. You also prevent bubbles during processing, which can lead to coverage problems in holes or microvias.

You gain a robust ceramic pcb that meets the demands of modern electronics. The combination of ceramic and copper ensures high reliability, superior thermal conductivity, and long-term performance.

Ceramic Substrate Materials

Alumina (Al2O3) Properties

You often see alumina as the most common ceramic in dpc ceramic pcb production. Alumina stands out because it combines affordability, availability, and a strong balance of properties. You benefit from its high hardness, which resists scratches and dents. This ceramic also provides excellent electrical insulation, keeping your circuits safe and reliable. Alumina maintains high thermal stability, performing well at temperatures up to 1600°C. Its good chemical resistance means it withstands acids, alkalis, and solvents, so your pcb lasts longer in harsh environments. Low thermal expansion helps your ceramic circuit board stay structurally sound, even with temperature changes.

| Property | Description |

|---|---|

| High Hardness | Resists scratches, dents, and wear from repeated use or contact with other materials. |

| Excellent Electrical Insulation | Blocks electricity from passing through, ensuring safety and performance. |

| High Thermal Stability | Performs well at high temperatures, often up to 1600°C. |

| Good Chemical Resistance | Not affected by most acids, alkalis, or solvents, enhancing durability. |

| Low Thermal Expansion | Minimizes expansion or contraction with temperature changes, maintaining structural integrity. |

- Thermal conductivity ranges from 15W/mK to 50W/mK, which supports efficient heat transfer in electronics.

- Alumina can operate at temperatures up to 300°C without losing performance.

- Melting points reach 1400°C for 96% alumina and 1600°C for 99% alumina.

You find alumina in a wide range of applications because of these properties. It appears in LED lighting, medical systems, communication systems, power storage, robot control, aerospace, new energy vehicles, inverters, sensors, coolers, solar energy, stabilizers, and laser equipment. Its low cost and versatility make it the top choice for ceramic pcb manufacturing.

Aluminum Nitride (AlN) Benefits

You choose aluminum nitride when you need high thermal conductivity and strong electrical insulation. AlN delivers thermal conductivity between 140–200 W/mK, far higher than alumina. This property makes it ideal for high-power electronics, where heat must move away from components quickly. AlN also matches the thermal expansion of semiconductor materials, which reduces stress and increases the mechanical stability of your pcb.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| AlN | 140–180 |

| Alumina | 20–30 |

Aluminum nitride resists chemicals and maintains stable performance in harsh environments. You see it used in device packaging, heat sinks, power amplifiers, RF devices, and high-brightness LEDs. Its insulation resistance can reach up to 10^14 Ω·cm, preventing short circuits and electrical hazards. AlN’s low thermal expansion coefficient helps your ceramic pcb survive rapid temperature changes without cracking.

| Advantage | Description |

|---|---|

| Thermal Conductivity | Ranges from 200 to 300 W/m·K, crucial for efficient heat dissipation in high-power applications. |

| Electrical Insulation Properties | Insulation resistance of up to 10^14 Ω·cm, preventing short circuits and electrical hazards. |

| Chemical Stability | Strong resistance to various chemicals, maintaining stable performance in harsh environments. |

| Low Thermal Expansion Coefficient | Matches well with semiconductor materials, reducing thermal stress damage. |

| Application in Device Packaging | Used as a substrate material, enhancing thermal management and electrical safety in semiconductor devices. |

| Heat Sink Design | Improves reliability and stability in power amplifiers, RF devices, and lasers by preventing overheating. |

| LED Technology | Enhances light emission efficiency and thermal management for high-brightness LEDs. |

You pay more for aluminum nitride than alumina, but you gain excellent thermal conductivity and reliability for demanding electronics.

Beryllium Oxide (BeO) Features and Safety

You turn to beryllium oxide when you need the highest thermal conductivity in a ceramic substrate. BeO offers values up to 330 W/mK, making it the best choice for extreme heat dissipation. It also provides strong electrical insulation and mechanical stability, which are essential for high-performance pcb designs.

However, you must consider safety and cost. BeO is more expensive than both alumina and aluminum nitride. Its use comes with strict safety protocols because inhaling beryllium oxide dust can cause serious lung disorders. You find risks in production areas such as metallization, reflow, testing, wire bonding, firing, and lid removal. Solid, fired BeO ceramics do not pose significant health risks if you follow safe handling practices, but airborne particles are hazardous.

⚠️ Note: Regulatory agencies like OSHA, USEPA, and USDOT set strict exposure limits for beryllium oxide. Chronic exposure can lead to berylliosis, a severe lung condition. Only specialized facilities with proper controls use BeO in ceramic PCB manufacturing.

You see BeO in specialized applications where its unique properties justify the higher price and safety measures. These include military, aerospace, and high-frequency electronics, where excellent thermal conductivity and electrical insulation are critical.

Summary Table: Cost and Availability

| Substrate Type | Cost per Kilogram (USD) | Availability |

|---|---|---|

| Alumina | $5 - $15 | Widely available |

| Aluminum Nitride | $80 - $150 | Limited suppliers |

| Beryllium Oxide | Higher than aluminum nitride | Less common, health risks involved |

You usually select alumina for most ceramic circuit board needs because it balances cost, performance, and safety. You choose aluminum nitride for high thermal conductivity and reliability in advanced electronics. You reserve beryllium oxide for specialized uses, always considering the strict safety and regulatory requirements.

Copper Layer in DPC Ceramic PCBs

Copper’s Role

You rely on copper to deliver outstanding electrical and thermal performance in every dpc ceramic pcb. The copper layer forms the conductive pathways that carry signals and power across your pcb. When you increase the thickness of the copper, you boost the current-carrying capacity and improve the durability of your ceramic circuit board. Thicker copper layers reduce electrical resistance, which allows higher current flow without excessive voltage drop. You also benefit from improved thermal conductivity, which helps your pcb dissipate heat more efficiently—a critical factor for high-power electronics.

| Copper Thickness | Current-Carrying Capacity (A/mm) |

|---|---|

| 1 oz | 1–1.5 |

| 2 oz | up to 2.5 |

| 3 oz and above | Higher for industrial applications |

- Thicker copper layers enhance mechanical strength, making your pcb more resistant to bending and thermal stress.

- You see these advantages in power modules, LED drivers, and industrial control systems, where reliability and heat management are essential.

- The right copper thickness ensures your ceramic pcb manufacturing process meets the demands of advanced electronics.

Copper-Ceramic Bonding

You achieve a reliable connection between copper and ceramic through advanced bonding mechanisms. The direct copper bonding process uses high temperatures to create a seamless interface. You start with surface deposition, which applies a metal seed layer to the ceramic substrate. Plating thickening follows, increasing the copper layer’s thickness for better conductivity and strength. Surface treatment further enhances the bond, ensuring the copper adheres tightly to the ceramic.

| Mechanism | Description |

|---|---|

| Surface Deposition | Involves the application of a metal seed layer on the ceramic substrate. |

| Plating Thickening | Refers to the process of increasing the thickness of the deposited copper. |

| Surface Treatment | Enhances the bonding characteristics between copper and the ceramic substrate. |

You gain high graphic precision, vertical interconnections, and excellent electrical conductivity. The copper-ceramic interface also delivers superior thermal conductivity and high insulation properties. These features make your pcb robust and reliable, even in demanding environments. You can trust the copper layer to maintain performance and stability throughout the life of your ceramic pcb.

Auxiliary Materials and Coatings

Adhesion Layers

You rely on specialized adhesion layers to create a strong bond between copper and ceramic in dpc ceramic pcb manufacturing. These layers play a vital role in maintaining the integrity of your ceramic circuit board, especially when exposed to high temperatures and demanding environments. You often see several types of adhesion layers used in the industry. Each type offers unique advantages for thermal conductivity, mechanical strength, and reliability.

| Adhesion Layer Type | Description |

|---|---|

| Copper Composite Layer | Bonded to cleaned ceramic using advanced film manufacturing or vacuum techniques. |

| Molybdenum or Tungsten | Thin layer deposited by sputtering, acting as an adhesive for copper. |

| High-Temperature Adhesive | Used for layering copper foil onto ceramic, repeated for desired thickness. |

| Chemical Copper Plating | Thickens copper, improves conductivity, and ensures better adhesion with sputtered copper. |

You select the adhesion layer based on your application’s requirements for thermal conductivity and durability. The right choice ensures your pcb withstands thermal cycling and mechanical stress, which is critical for high-performance electronics.

Surface Finishes

You protect your pcb’s copper circuitry with surface finishes that enhance both solderability and corrosion resistance. These finishes serve two main purposes: they provide a solderable surface for mounting components and shield exposed copper from oxidation. You must consider component types, production volume, durability, environmental impact, and cost when choosing a finish.

- Surface treatments protect copper pads and traces from damage.

- They prevent rusting and facilitate easier soldering.

- The finish directly affects the pcb’s ability to resist corrosion and maintain reliable solder joints.

You often choose ENIG (Electroless Nickel Immersion Gold) for harsh environments because it offers excellent corrosion resistance and stability. HASL (Hot Air Solder Leveling) is less suitable for demanding conditions due to its uneven surface and lower corrosion resistance. Immersion Silver provides good conductivity but can tarnish, so you need careful handling and storage.

A surface finish is essential for reliable connections and long-term performance in ceramic pcb manufacturing. The right finish helps your ceramic circuit board maintain high thermal conductivity and durability, even in challenging environments.

Ceramic PCB Boards: Comparative Properties

When you compare ceramic pcb boards, you see clear differences in thermal conductivity, electrical insulation, and mechanical strength. Your choice of substrate directly affects the thermal performance, reliability, and safety of your electronics.

Thermal Conductivity

You need high thermal conductivity for efficient heat dissipation in power electronics. The table below shows how each ceramic material performs:

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Beryllium Oxide (BeO) | 250–300 |

| Aluminum Nitride (AlN) | 170–230 |

| Alumina (Al₂O₃) | 20–30 |

Beryllium oxide provides excellent thermal conductivity, making it ideal for hybrid ceramic pcbs and high-power applications. Aluminum nitride pcb substrates also deliver high thermal conductivity, supporting advanced electronics and thick-film ceramic pcbs. Alumina works well for general use, including thin-film ceramic pcbs, but offers lower thermal performance.

Electrical Insulation

You rely on strong electrical insulation to prevent short circuits and ensure safety in your pcb. Each ceramic substrate offers unique dielectric properties:

- Beryllium oxide gives you high voltage resistance and a dielectric strength of 10–16 kV/mm, suitable for demanding environments.

- Aluminum nitride matches BeO in insulation capability, making it essential for low-temperature co-fired ceramic and high-temperature co-fired ceramic designs.

- Alumina provides reliable insulation for most electronics, supporting a wide range of pcb types.

Mechanical Strength

Mechanical stability and environmental resistance are critical for your ceramic circuit board. The table below highlights the differences:

| Material | Mechanical Strength Characteristics |

|---|---|

| Aluminum Nitride | Incredible mechanical strength, withstands harsh environments up to 2200°C, resists cracking and deformation. |

| Beryllium Oxide | Superior strength and hardness, melting point around 2570°C, excellent corrosion resistance, ideal for hybrid ceramic pcbs. |

| Alumina | Good mechanical stability, cost-effective, suitable for general electronics and thick-film ceramic pcbs. |

You select alumina for cost-effective solutions and general electronics. Aluminum nitride suits high-power and high-temperature resistance needs. Beryllium oxide excels in extreme conditions but requires careful handling due to safety concerns.

Tip: Always match the ceramic substrate to your application’s requirements for thermal conductivity, electrical insulation, and mechanical stability. This approach ensures your pcb delivers reliable performance and long service life.

Performance and Application Suitability

Material Choice and Real-World Use

You need to match the right ceramic material to your application to achieve the best pcb performance. Each ceramic offers unique benefits for electronics. When you design high-frequency or high-power pcb systems, you must consider several factors:

- Dielectric constant (Dk): Lower values help you achieve higher characteristic impedance, which is important for signal integrity.

- Loss tangent (tan δ): Lower values reduce signal attenuation, which keeps your circuits efficient.

- Thermal expansion coefficient (CTE): A lower CTE minimizes stress during temperature changes, which protects your pcb from cracking.

You also need to weigh technical and cost factors. Technical aspects include how well the ceramic fits your design, how easy it is to process, and how long you expect the product to last. Cost factors include the price of the ceramic, quality control, and how easy it is to source the material.

Ceramic substrates stand out in high-power and high-frequency electronics. Their high thermal conductivity and electrical insulation make them ideal for demanding environments. For example, in high-power LED lighting, ceramic pcbs help dissipate heat efficiently. This prevents overheating and extends the lifespan of your LEDs. You can often eliminate the need for bulky heat sinks by using ceramic substrates.

Application Examples

You see ceramic pcb technology in many industries. The table below shows how different sectors use these materials:

| Industry | Application Description |

|---|---|

| Automotive | Multilayer ceramic pcbs manage electric vehicle battery systems and support high-frequency, high-power components. |

| Aerospace | DPC substrates power RF and microwave components that demand low loss and high reliability. |

You also find ceramic pcbs in high-power LED modules. Their superior thermal conductivity and electrical insulation protect sensitive circuits and boost performance. In these applications, ceramic substrates help you achieve compact designs without sacrificing reliability.

Tip: Choose the ceramic material that matches your application's needs. This decision ensures your pcb delivers stable performance and long service life in advanced electronics.

You rely on alumina, aluminum nitride, beryllium oxide, and copper to build ceramic pcb boards that meet demanding standards. Their unique properties—thermal conductivity, electrical insulation, and mechanical strength—drive performance and application suitability. When you select materials, balance technical needs with safety concerns.

| Consideration | Description |

|---|---|

| Thermal Conductivity | Essential for heat dissipation in high-power applications, impacting performance and safety. |

| Electrical Insulation | Critical for preventing short circuits and ensuring safe operation of the PCB. |

| Mechanical Strength | Important for durability and reliability under operational stresses. |

| Manufacturing Process | Affects the precision and quality of the ceramic substrates, influencing overall performance. |

- Alumina gives you reliable strength and shock resistance.

- Aluminum nitride extends operational lifetimes with superior thermal management.

- Beryllium oxide offers unmatched conductivity but requires strict safety protocols.

Tip: Always evaluate both technical and safety factors before choosing materials for ceramic pcb boards.

HOME

HOME