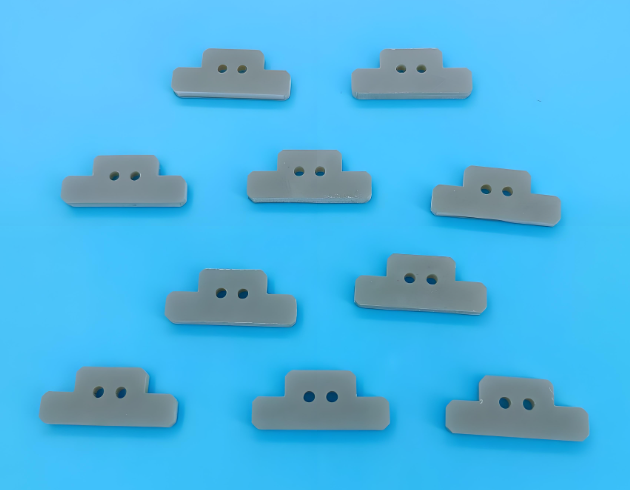

Rectangle Aluminum Nitride Substrate Ceramic PCB Manufacturer

Aluminum nitride (AlN) has become one of the most important materials in modern electronics due to its exceptional thermal and electrical properties. When formed into rectangular substrates, AlN provides a reliable, high-performance foundation for power devices, LEDs, RF circuits, and hybrid electronic modules.

The rectangular shape is preferred in many applications because it simplifies component layout, allows better thermal management, and matches standard circuit geometries. Coupled with its high thermal conductivity and excellent electrical insulation, rectangular AlN substrates enable compact, high-power designs that would be difficult to achieve with other materials.

What is a Rectangle Aluminum Nitride Substrate?

A rectangle aluminum nitride substrate is a ceramic base material made from high-purity AlN powder, pressed and sintered into a flat, rectangular shape. The rectangular form factor is widely used because it easily integrates into PCBs, power modules, LED arrays, and hybrid circuits.

Rectangular substrates are produced in various dimensions, typically ranging from 10 × 10 mm small dies to large panels exceeding 1000 × 1000 mm for industrial or automotive applications. Thicknesses vary from 0.2 mm to 2 mm or more, depending on mechanical strength and thermal performance requirements.

Unlike round or square substrates, rectangular substrates provide predictable layout areas and simplified metallization patterns, which is why they dominate power electronics and high-frequency packaging.

Key Properties of Aluminum Nitride Substrates

- Thermal Conductivity: AlN exhibits high thermal conductivity, typically 170–200 W/m·K, allowing efficient heat dissipation from high-power devices.

- Electrical Insulation: With resistivity ranging 10¹³–10¹⁴ Ω·cm, AlN provides excellent electrical isolation even at high voltages.

- Coefficient of Thermal Expansion (CTE): Approximately 4.5–5.5 × 10⁻⁶ /K, close to silicon, reducing stress in hybrid circuits.

- Mechanical Strength: High flexural strength ensures substrates can withstand handling, assembly, and operational stresses.

- Chemical Stability: AlN resists moisture and chemical attack, making it suitable for harsh environments.

- Surface Finish: Can be polished or lapped to achieve flatness <5 μm and roughness <50 nm, critical for thin-film or thick-film processes.

Applications of Rectangle AlN Substrates

Rectangle AlN substrates are used across diverse industries where high thermal conductivity and insulation are required. Typical applications include:

- Power electronics modules

- High-power LEDs

- RF and microwave circuits

- Hybrid thick-film circuits

- High-frequency IC mounting

- Sensor substrates

- Microwave power amplifiers

- Laser diode packages

- High-reliability electronic assemblies

Design Considerations for Rectangle Aluminum Nitride (AlN) Substrates

When designing a rectangular AlN substrate, engineers must carefully consider electrical, thermal, and mechanical requirements. Key factors include:

1. Dimensions and Thickness

Substrate size and thickness directly affect heat dissipation and mechanical stability. Typical thickness ranges from 0.2–2 mm, while length and width are customized to match device layouts, ensuring optimal thermal performance and structural reliability.

2. Surface Finish

Polished surfaces are essential for thin-film metallization and die bonding, achieving smoothness below 50 nm. Lapped surfaces may be used for thick-film circuits, balancing cost and adhesion without compromising electrical performance.

3. Thermal Management

AlN’s high thermal conductivity (170–200 W/m·K) efficiently spreads heat from high-power devices. Power densities of 1–2 W/cm² are typical for LED or power modules to maintain safe junction temperatures and prolong device life.

4. Electrical Insulation and Metallization

Dielectric strength must exceed 10 kV/mm for high-voltage applications. Cu, Au, or Ni metallization layers (5–50 μm) are applied to match device design, providing reliable electrical connections and long-term stability.

5. Coefficient of Thermal Expansion (CTE) Matching

AlN’s CTE (4.5–5.5 ×10⁻⁶ /K) closely matches silicon and GaN, minimizing thermal stress during operation. Proper CTE alignment prevents substrate cracking and maintains adhesion under thermal cycling in hybrid circuits.

6. Environmental and Mechanical Considerations

Substrates must withstand vibration, thermal cycling, and moisture exposure. Rectangular designs allow predictable layouts, reducing stress concentrations and ensuring reliable performance in automotive, aerospace, and industrial applications.

Manufacturing Process of AlN Ceramic Substrates

Producing high-quality AlN substrates requires a precise sequence of steps to ensure thermal conductivity, mechanical strength, and electrical insulation. Each stage must be carefully controlled to meet stringent industry standards.

1. Powder Preparation

The first step in producing high-quality AlN substrates is the preparation of raw powders. High-purity AlN powder is blended with sintering additives, typically Y₂O₃ or CaO, to enhance densification during sintering. The powders are carefully mixed to ensure homogeneity, which is critical for achieving consistent thermal conductivity and mechanical strength in the final substrate.

2. Shaping / Forming

After powder preparation, the AlN mixture is shaped into the desired rectangular substrate form. Techniques such as uniaxial pressing, isostatic pressing, or tape casting are commonly used. The choice of method depends on the substrate size, thickness, and required dimensional precision.

3. Sintering

Shaped AlN substrates are then sintered at high temperatures, typically between 1700°C and 1900°C, in a controlled atmosphere. Sintering densifies the material, enhances thermal conductivity, and strengthens the mechanical structure. Precise temperature ramp-up and hold times are critical to prevent cracking and to achieve a uniform microstructure.

4. Lapping and Polishing

Once sintered, the substrates undergo mechanical lapping and polishing to achieve precise flatness and surface finish. Polished surfaces are essential for thin-film metallization or die bonding. Typical flatness is maintained within <5 μm, and surface roughness is controlled below 50 nm.

5. Metallization / Coating

For many applications, AlN substrates are coated with conductive layers such as Cu, Au, or Ni to form electrical connections or pads for mounting devices. Metallization patterns can be customized based on the final application, whether for thick-film or thin-film circuits.

6. Inspection and Testing

Each substrate undergoes thorough inspection, including dimensional measurement, flatness verification, thermal conductivity testing, dielectric strength evaluation, and mechanical strength assessment. Only substrates meeting all specifications proceed to final assembly or shipment.

Technical Specifications of Rectangle AlN Substrates

|

Parameter |

Typical Range / Value |

|

Length × Width |

10 × 10 mm – 1000 × 1000 mm |

|

Thickness |

0.2 – 2 mm |

|

Thermal Conductivity |

170–200 W/m·K |

|

Electrical Resistivity |

10¹³–10¹⁴ Ω·cm |

|

CTE |

4.5–5.5 × 10⁻⁶ /K |

|

Flexural Strength |

200–400 MPa |

|

Surface Roughness |

<50 nm |

|

Flatness |

<5 μm |

|

Dielectric Strength |

>10 kV/mm |

|

Metallization Thickness |

5–50 μm |

|

Thermal Shock Resistance |

50–100 cycles |

|

Maximum Operating Temperature |

1000°C (short-term) |

How to Test and Validate AlN Substrates?

- Visual Inspection – Detect cracks, chips, or surface defects.

- Dimensional Verification – Confirm length, width, thickness, and flatness meet design tolerances.

- Thermal Conductivity Testing – Measure heat transfer efficiency.

- Electrical Insulation Test – Verify resistivity and dielectric strength.

- Mechanical Strength / Flexural Testing – Confirm substrates can withstand handling and operational stress.

- Environmental Testing – Thermal cycling, moisture exposure, and vibration tests for reliability.

Systematic testing ensures substrates meet performance specifications and function reliably in demanding applications.

Why Choose Best Technology for AlN Substrates?

At Best Technology, we provide comprehensive solutions beyond simple substrate supply:

- Custom Design Support – Tailored dimensions, thickness, metallization, and surface finish.

- Engineering Assistance – Guidance on thermal management, electrical insulation, and device integration.

- Full Process Control – Traceability and quality control through MES systems.

- Prototyping and Small-Batch Production – Supports early-stage design and pilot runs.

- Testing and Validation Services – Thermal, electrical, mechanical, and environmental testing.

- Flexible Manufacturing – Standard and custom sizes, rigid or large-area substrates.

We help customers integrate AlN substrates into high-power modules, LED arrays, RF devices, and more, providing ready-to-use, reliable solutions.

Rectangle aluminum nitride substrates combine exceptional thermal conductivity, electrical insulation, and mechanical stability, making them indispensable in modern electronics. They support high-power devices, compact thermal designs, and hybrid circuits in automotive, aerospace, medical, and industrial applications.

Best Technology delivers high-precision AlN substrates with flexible design, advanced metallization, rigorous testing, and end-to-end support. Partnering with us ensures reliable performance, optimized thermal management, and smooth integration into your electronic systems.

FAQs about AlN Ceramic PCB

1. Can AlN substrates be customized in size and thickness?

Yes, rectangular AlN substrates can be produced in various dimensions, typically from 10 × 10 mm up to 1000 × 1000 mm, with thicknesses ranging from 0.2 mm to 2 mm or more, depending on thermal and mechanical requirements.

2. What types of metallization are compatible with AlN substrates?

Common metallization options include copper (Cu), gold (Au), and nickel (Ni). These can be applied for thin-film or thick-film circuits, ensuring excellent adhesion, electrical conductivity, and thermal performance.

3. How do you ensure the reliability of AlN substrates under high-power operation?

Reliability is ensured through rigorous testing, including thermal conductivity measurement, electrical insulation testing, mechanical flexural tests, and environmental testing such as thermal cycling, humidity exposure, and vibration.

4. Why should I choose Best Technology for AlN substrate solutions?

Best Technology offers custom design support, high-precision lapping and polishing, metallization options, full testing and validation, prototyping and mass production services, and engineering consultation, providing end-to-end solutions for high-performance applications.

HOME

HOME