What is Aluminium Nitride? Types of Ceramic PCB Material

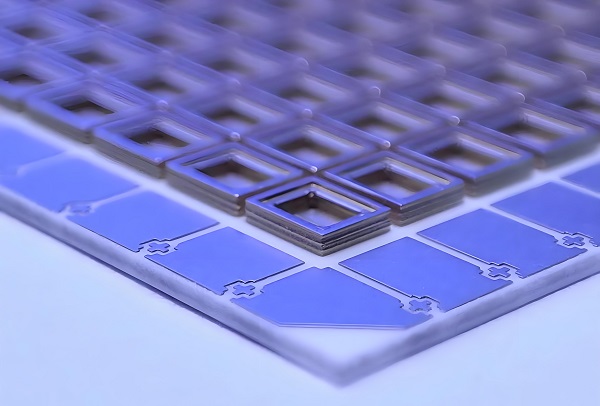

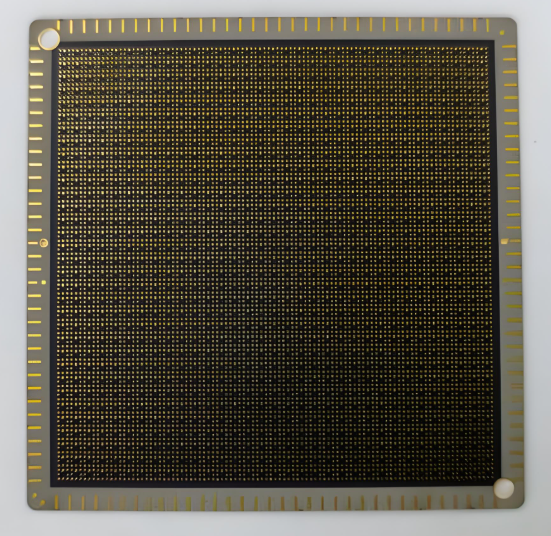

Aluminium nitride is one of the most valuable ceramic materials used in modern electronics. In PCB manufacturing, it is recognized for its superior thermal conductivity, electrical insulation, and chemical stability. As technology advances, the demand for high-performance substrates grows. Engineers and product designers now look at materials like alumina, aluminium nitride, and silicon nitride to achieve higher efficiency and reliability in their circuits.

This article explores aluminium nitride in detail—its properties, composition, formula, and uses—while also comparing it with other ceramic PCB materials.

What is Aluminum Nitride Ceramic?

Aluminium nitride ceramic (often written as AlN) is a compound made of aluminium and nitrogen. It is a covalently bonded ceramic with outstanding thermal conductivity, often reaching 170–200 W/m·K, much higher than alumina ceramics. Despite its ability to transfer heat quickly, it remains electrically insulating, making it a rare combination that is highly valued in electronics.

In the PCB industry, aluminium nitride substrates are widely used for power modules, LED packaging, laser diodes, and RF applications. Its high thermal performance helps reduce overheating and extends the life of components.

What is the Color of Aluminium Nitride?

Aluminium nitride ceramics typically appear in gray to off-white shades. In powder form, it is usually grayish white. When sintered into ceramic substrates, the surface becomes slightly lighter with a smooth finish. The color difference depends on the purity level and processing method, but overall it remains within the gray-white spectrum.

What Materials are Used as Ceramic Substrates?

In the PCB field, ceramic substrates act as the foundation for electronic circuits. They provide insulation while also managing heat. The most common ceramic materials include:

- Alumina (Al₂O₃): The most widely used ceramic substrate, cost-effective, and stable, but with lower thermal conductivity (20–30 W/m·K).

- Aluminium Nitride (AlN): High thermal conductivity and excellent electrical insulation. Suitable for high-power devices.

- Silicon Nitride (Si₃N₄): Strong mechanical strength, high reliability under thermal shock, used in automotive and aerospace electronics.

- Beryllium Oxide (BeO): Very high thermal conductivity but less commonly used due to toxicity concerns.

Each material has unique advantages. Aluminium nitride stands out as the best balance between performance and safety, especially for high-reliability PCBs.

Percentage of Aluminium in Aluminium Nitride

The chemical composition of aluminium nitride is straightforward. It contains one aluminium atom and one nitrogen atom per molecule. In terms of weight percentage:

- Aluminium (Al): 65.81%

- Nitrogen (N): 34.19%

This balance of elements gives AlN its unique crystalline structure and properties.

Aluminum Nitride Material Properties

|

Property |

Value / Range |

|

Thermal Conductivity |

170–200 W/m·K |

|

Electrical Resistivity |

~10¹² Ω·cm |

|

Dielectric Constant (1 MHz) |

8–9 |

|

Thermal Expansion Coefficient |

4.5 × 10⁻⁶ /K |

|

Flexural Strength |

~300–350 MPa |

|

Hardness (Vickers) |

~1100 HV |

|

Density |

3.26 g/cm³ |

|

Melting Point |

~2200°C |

|

Chemical Resistance |

Stable against most molten metals |

What is the Chemical Formula of Aluminium Nitride?

The chemical formula of aluminium nitride is AlN. It belongs to the hexagonal crystal system, similar to wurtzite (ZnS structure). Its simple yet strong chemical bond between aluminium and nitrogen gives it stability at high temperatures and outstanding performance in electronic applications.

What is Aluminium Nitride Used For?

Aluminium nitride finds applications across industries due to its dual role as a thermal conductor and electrical insulator. Common uses include:

- Ceramic PCBs: Used in power electronics, automotive control units, and communication devices.

- LED Packaging: Efficiently removes heat from high-brightness LEDs.

- RF & Microwave Devices: Provides stable dielectric performance at high frequencies.

- Power Modules: Essential in IGBT and MOSFET modules for cooling.

- Optoelectronics: Laser diodes, sensors, and photonics packaging.

- Microelectronics: Substrates for ICs and multilayer circuits.

Its adoption is increasing as devices demand higher power density and better thermal management.

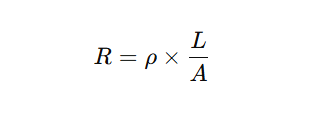

How to Calculate Resistance of Aluminium Nitride?

The resistance of an aluminium nitride substrate can be estimated using Ohm’s law and the resistivity formula:

Where:

- R = resistance (Ω)

- ρ = resistivity of AlN (10¹² Ω·cm)

- L = length of the path (cm)

- A = cross-sectional area (cm²)

Since AlN has extremely high resistivity, it acts almost like a perfect insulator. In practice, resistance values are so high that current leakage is negligible.

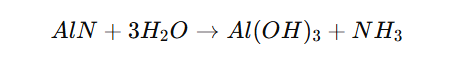

What Happens When Aluminium Nitride Reacts with Water?

Although aluminium nitride is chemically stable, it reacts slowly with water, especially at high temperatures. The reaction can be represented as:

This means aluminium nitride reacts with water to form aluminium hydroxide and ammonia gas. In real applications, AlN substrates are usually protected with coatings or used in dry environments to prevent hydrolysis.

Why Choose Best Technology as Your Aluminium Nitride Ceramic PCB Supplier?

Selecting the right supplier is as important as choosing the right material. Aluminium nitride PCBs require advanced production technology, strict quality control, and deep industry knowledge. At Best Technology, we combine all three to give customers reliable solutions that drive performance and efficiency. At here, you can enjoy:

- IATF16949, AS9100D, RoHS, UL certificated

- Professional engineer team guides you from design review to final production, solving potential challenges such as heat dissipation, metallization, and dimensional stability.

- Competitive price that makes you high value for money

- Fast turnaround service from prototypes to small and medium-volume production

- Besides aluminium nitride, we also supply alumina, silicon nitride, and other ceramic PCB materials

FAQs about Aluminium Nitride

1. Is aluminium nitride better than alumina for PCBs?

Yes, aluminium nitride has much higher thermal conductivity than alumina, making it better for high-power and heat-sensitive devices.

2. Can aluminium nitride substrates be used in automotive electronics?

Absolutely. With excellent thermal shock resistance and stable performance, aluminium nitride is widely used in automotive control units and power modules.

3. Is aluminium nitride safe to handle?

Yes, aluminium nitride ceramics are safe in solid form. The main concern is fine powder inhalation during manufacturing, which is controlled under safety standards.

4. Why is aluminium nitride expensive compared to other ceramic substrates?

Its high production cost comes from complex sintering processes and the purity required. However, its performance benefits justify the investment in many industries.

5. Does aluminium nitride work well with multilayer PCBs?

Yes, AlN substrates can support multilayer structures. Their thermal properties help manage heat in compact, high-density circuits.

HOME

HOME