What is the Composition of ENEPIG, Electrical/Thermal Conductivity and Thickness?

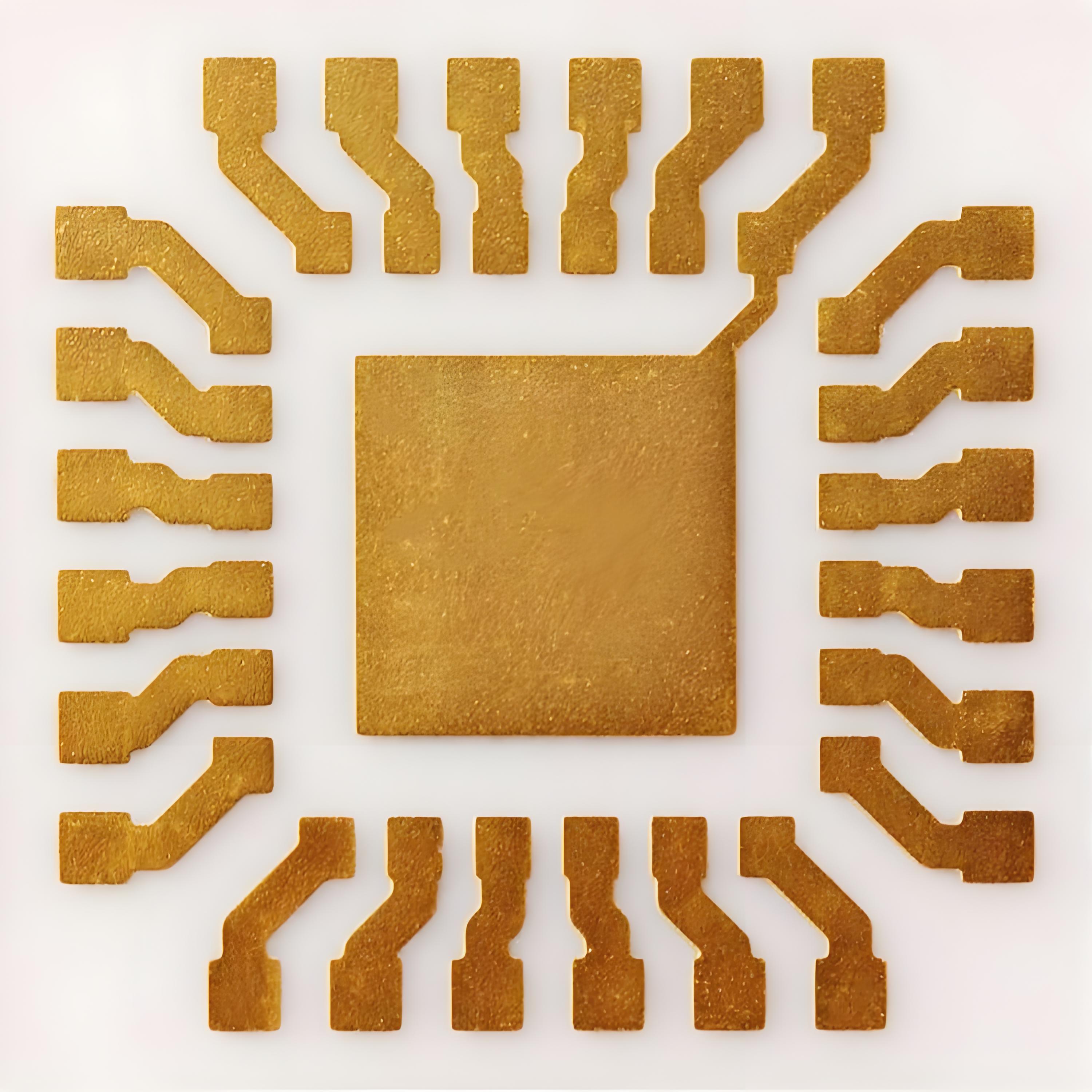

ENEPIG stands for Electroless Nickel Electroless Palladium Immersion Gold. It’s a multi-layer surface finish used in PCB manufacturing to enhance solderability, wire bonding, and corrosion resistance. ENEPIG is especially suitable for high-density designs, RF modules, and ceramic-based PCBs due to its support for both gold and aluminum wire bonding, as well as excellent environmental stability. Today, we would like to introduce the composition, plating thickness, and electrical/thermal conductivity of ENEPIG surface finishing.

1. Composition

Copper (Cu) Base: PCB substrate (not part of the ENEPIG layers but serves as the foundation).

Chemical Nickel (Ni-P): Forms a phosphorus-containing nickel layer (typically 3-10% phosphorus) as a diffusion barrier and solderable base 148.

Chemical Palladium (Pd): Pure palladium layer acting as a corrosion inhibitor.

Immersion Gold (Au): Thin gold layer providing oxidation resistance and surface connectivity

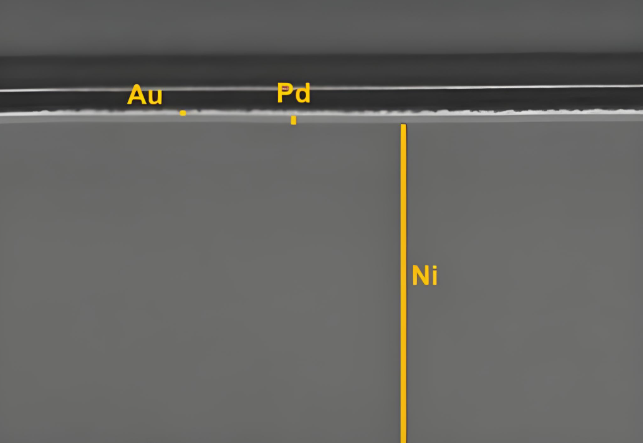

2.Layer Thickness Ranges

|

Layer |

Thickness Range |

Key Functions |

|

Nickel (Ni-P) |

3-6 μm (120-240 μinches) |

Barrier against copper diffusion; foundation for soldering. |

|

Palladium (Pd) |

0.05-0.15 μm (2-6 μinches) |

Prevents nickel oxidation ("black pad"); enhances solder joint reliability. |

|

Gold (Au) |

0.03-0.1 μm (1.2-4 μinches) |

Anti-corrosion; ensures surface solderability and wire-bond compatibility. |

3. Electrical Conductivity

Surface Conductivity: Dominated by the gold layer (conductivity: 70 MS/m), enabling low-contact resistance for signals and connectors.

Via/Through-Hole Conductivity: Nickel layer (conductivity: 10-15 MS/m) becomes critical. Its higher resistivity than copper can marginally increase impedance in high-current paths.

High-Frequency Performance: Thin gold (<0.1 μm) minimizes "skin effect" losses, making ENEPIG suitable for RF/microwave PCBs

4. Thermal Conductivity

Nickel Layer: ~90 W/m·K (acts as primary thermal path from components to substrate).

Palladium/Gold: Pd (~70 W/m·K) and Au (~320 W/m·K) contribute minimally due to their thinness.

Overall Impact: ENEPIG’s total thickness (3.1-6.3 μm) has negligible effect on bulk thermal resistance. Heat dissipation is dominated by the PCB substrate (e.g., metal-core PCBs: 160-400 W/m·K)

5. Conclusion

ENEPIG’s multilayer structure balances solderability, corrosion resistance, and electrical performance. Its nickel layer (3-6 μm) provides robustness, palladium (0.05-0.15 μm) prevents failures, and gold (0.03-0.1 μm) ensures surface conductivity. While thermal properties are substrate-dependent, electrical performance excels in high-frequency designs. Recent advances enable thinner layers for 5G/millimeter-wave application

HOME

HOME