What is the Difference Between Alumina and Aluminum PCB?

When selecting a PCB material for thermal management or high-power designs, two names often cause confusion—alumina and aluminum. While they sound similar, they offer very different performance characteristics and are built for distinct roles. Let’s break it all down so you can make a smarter decision for your design needs.

What is alumina PCB and how is it different from aluminum PCB?

At a glance, alumina and aluminum PCBs serve similar roles—heat dissipation and structural support—but they are fundamentally different in composition. Alumina PCBs are made from aluminum oxide ceramic, offering excellent thermal conductivity and electrical insulation in one solid layer. On the other hand, aluminum PCBs are built on a metal core made of aluminum, topped with a dielectric layer and then the copper circuit.

While aluminum PCBs are more common in consumer electronics due to cost-effectiveness, alumina PCBs are reserved for applications that require extreme temperature stability, voltage isolation, and precision. Aluminum is a conductive metal that needs insulating materials to function, while alumina is already an insulating ceramic, making it ideal for high-performance applications.

Which has better thermal conductivity: alumina or aluminum PCB?

This question gets asked a lot, and it’s a good one. While aluminum as a raw metal has high thermal conductivity—about 205 W/m·K—the actual thermal performance of aluminum PCBs is limited by the dielectric layer, which typically offers only 1 to 3 W/m·K. That bottleneck reduces real-world heat transfer efficiency.

In contrast, alumina PCBs typically offer thermal conductivities of 20–30 W/m·K in bulk ceramic form, with higher-grade variants reaching even more. This makes them more efficient in moving heat directly from source to ambient without a layered stack-up. In thermal-critical designs like laser modules or power amplifiers, alumina often outperforms aluminum in terms of sustained thermal management.

Is alumina PCB better for high-frequency applications?

Yes—alumina PCBs are typically superior in high-frequency or RF applications. That’s because they have a low dielectric loss, tight tolerances, and stable electrical properties even at very high frequencies. Alumina also resists signal distortion due to its uniform structure and low surface roughness, which reduces reflection and signal attenuation.

Aluminum PCBs, on the other hand, are more prone to signal leakage, especially if the dielectric layer is inconsistent or thick. This makes them less ideal for critical RF or microwave circuits, where signal integrity is paramount.

What are the pros and cons of using aluminum PCBs?

Aluminum PCBs are widely used for a reason—they strike a practical balance between thermal performance and manufacturing cost. Here’s a quick look:

Pros:

- Excellent mechanical strength

- Lower cost than ceramic alternatives

- Good heat dissipation for moderate power levels

- Lightweight and relatively easy to machine

- Well-suited for LED lighting, power supplies, and motor control

Cons:

- Requires a dielectric layer for insulation, which can limit performance

- Lower dielectric strength and frequency stability

- Not ideal for high-voltage or high-frequency applications

- Corrosion risk if not properly coated or anodized

Why is alumina used in some PCB applications despite the higher cost?

Alumina comes with a higher price tag due to the complex processing involved in ceramic fabrication and copper bonding. However, this extra investment pays off in specialized industries where failure is not an option.

Medical devices, aerospace controls, military-grade electronics, and laser modules often require:

- Extreme thermal reliability

- Minimal expansion under heat (low CTE)

- High voltage isolation

- Stable RF performance

In these fields, alumina’s reliability and precision justify the cost. The material behaves predictably under stress, which is critical in environments where failure could be catastrophic.

Can aluminum PCBs replace ceramic PCBs like alumina in all cases?

Not quite. Aluminum PCBs are a great solution for many applications, especially where budget constraints matter and extreme precision isn’t required. But in environments with continuous high power, tight thermal tolerances, or RF signal transmission, alumina PCBs offer far better performance.

Trying to replace a ceramic PCB with aluminum could lead to:

- Inconsistent thermal dissipation

- Dielectric breakdown under high voltages

- RF interference or loss in signal strength

- Shortened product life cycle due to thermal fatigue

So, while aluminum PCBs are versatile, they can't fully substitute alumina in mission-critical applications.

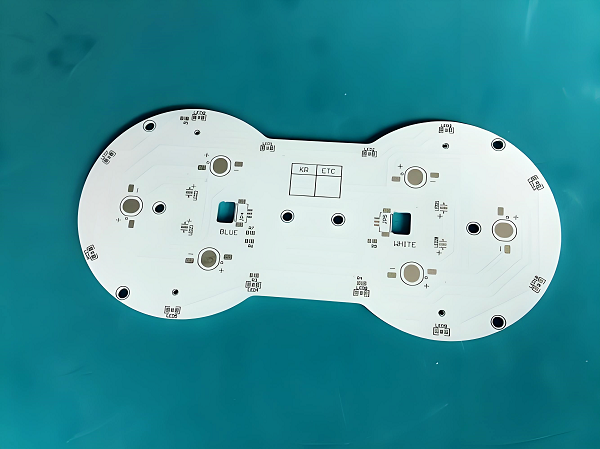

What are the main applications of alumina and aluminum PCBs?

Here's where things get more contextual. Both materials have strong markets, but they serve different needs.

Alumina PCB Applications:

- Medical implants and diagnostics

- Military communication systems

- Laser and photonics devices

- High-frequency radar systems

- Power electronics in aerospace

Aluminum PCB Applications:

- LED lighting modules

- Power converters and inverters

- Consumer electronics chargers

- Automotive headlight assemblies

- HVAC motor controllers

So, if you're working on mass-market power electronics, aluminum is likely the fit. For precision instruments, alumina takes the lead.

How do I choose between alumina and aluminum PCB for my project?

It comes down to three main questions:

- What’s the operating environment like? High temperatures and voltages point to alumina.

- How critical is thermal performance and electrical isolation? If it’s essential, alumina wins.

- What’s your volume and budget? For high-volume, low-cost production, aluminum may be a smarter choice.

If you're building something durable, compact, and thermally intense, don’t default to the cheaper option. Let the performance requirements lead the material decision.

FAQs

1. Can I use aluminum PCB for high-power applications?

Yes, aluminum PCBs can handle moderate power levels, especially in applications like LED lighting or power adapters. However, for continuous high-power or heat-intensive applications, alumina PCBs provide better thermal stability and reliability.

2. Are alumina PCBs more fragile than aluminum PCBs?

Alumina PCBs are indeed more brittle due to their ceramic nature, but they’re also more dimensionally stable under thermal and mechanical stress. Proper handling and design precautions can mitigate breakage risks.

3. What’s the main reason companies choose aluminum PCBs over alumina?

Cost is the primary factor. Aluminum PCBs are cheaper to produce and are suitable for most general-purpose electronics, especially when high-frequency or high-voltage performance isn't critical.

4. Do alumina PCBs require a separate insulating layer like aluminum PCBs?

No, alumina is naturally an excellent electrical insulator, so it doesn't need a dielectric layer. This gives it an advantage in thermal efficiency and electrical reliability.

5. Is there a hybrid option that combines benefits of both materials?

Yes, some advanced PCB solutions use aluminum substrates with high-performance dielectric materials or combine ceramic and metal layers in a hybrid stack-up. These are customized for specific high-end applications where balanced performance is needed.

HOME

HOME