What Is the Thinnest Ceramic Material for RF Devices?

For RF devices, the thinnest ceramic material often depends on the substrate type and the specific frequency range. In general, manufacturers of high-frequency ceramics like Alumina (Al₂O₃), Aluminum Nitride (AlN), and Beryllium Oxide (BeO) can provide substrates down to very small thicknesses.

Why Ceramic Substrates Are Critical in RF Applications?

Ceramic substrates hold a special place in RF engineering because they combine electrical reliability with mechanical strength. Unlike polymer-based laminates, ceramics remain dimensionally stable at high temperatures and under heavy electrical loads. Their low dielectric loss reduces unwanted signal attenuation, which is crucial in applications operating in the GHz range. In addition, ceramics offer excellent insulation and support consistent performance even when devices run at high power densities.

For RF engineers, these benefits translate into compact, high-performance circuits capable of functioning in demanding environments. As devices shrink in size—especially in wireless modules, radar systems, and IoT applications—the demand for thinner ceramic substrates has grown significantly.

How Thin Can Alumina Substrates Be Manufactured?

Alumina (Al₂O₃) remains one of the most common ceramic materials used in RF circuits. Its wide availability, cost-effectiveness, and reliable dielectric properties make it a natural choice. The material is often produced in thicknesses ranging from 0.1 mm (100 µm) to several millimeters.

For RF device manufacturers, 0.1 mm represents the thinnest practical thickness for alumina while still maintaining strength during handling and processing. This thin substrate supports compact designs for components such as filters, oscillators, and resonators, where both footprint reduction and signal consistency are required. Going below this thickness is technically possible, but risks increase significantly in terms of mechanical fragility.

How Thin Is Aluminum Nitride in RF Power Devices?

Aluminum Nitride (AlN) is another widely used ceramic material, valued for its high thermal conductivity—up to 180 W/m·K, far exceeding that of alumina. This makes AlN particularly suitable for high-power RF devices where heat dissipation is a key concern, such as power amplifiers and radar modules.

AlN substrates are typically manufactured starting from 0.15 mm thickness, although some suppliers can process slightly thinner wafers on request. While not as thin as alumina, AlN’s superior thermal management justifies its use in many high-power systems. Engineers often prioritize thermal stability over extreme thinness in such cases, since overheating can degrade RF performance far more severely than minor size differences.

Why Is LTCC Considered the Best Option for Miniaturization?

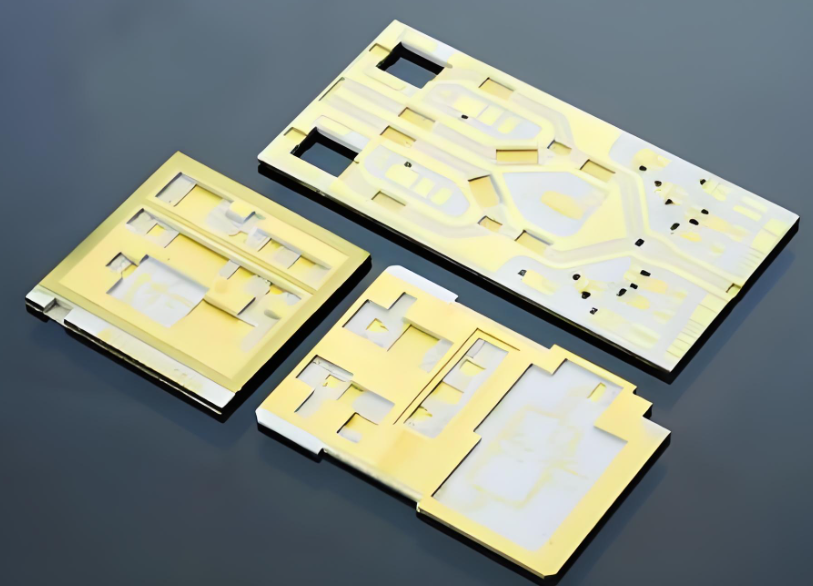

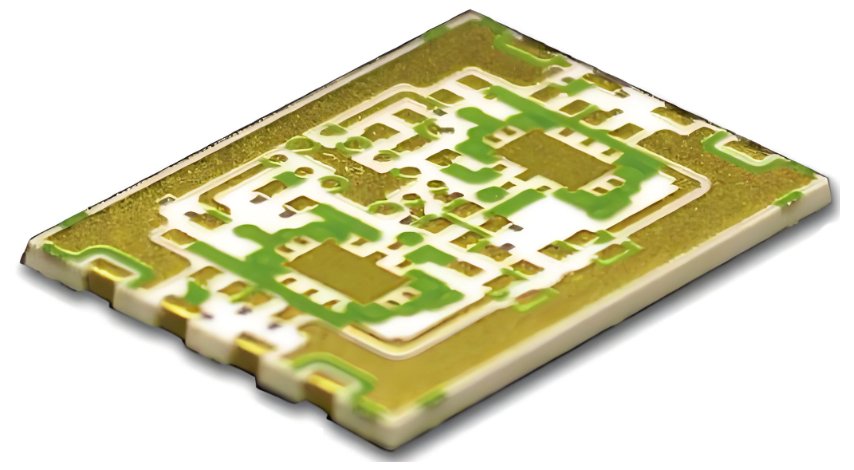

Low Temperature Co-fired Ceramic (LTCC) has transformed RF circuit design by enabling multilayer integration. LTCC substrates are made by stacking multiple thin ceramic tapes—each layer as thin as 50–100 µm—and firing them together at relatively low temperatures. This process allows not only thinner layers but also the embedding of passive components like resistors, inductors, and capacitors directly into the ceramic structure.

The ability to integrate several functions into one compact module makes LTCC indispensable in modern RF applications such as smartphones, 5G antennas, GPS modules, and automotive radar systems. Its thin layering capability supports extreme miniaturization without sacrificing dielectric stability. Among commercially viable options, LTCC offers the thinnest ceramic solution currently available.

How Does HTCC Compare to LTCC in Thickness and Use?

High Temperature Co-fired Ceramic (HTCC) differs from LTCC in its firing process and resulting characteristics. While HTCC substrates typically start at around 100 µm thickness per layer, they are more robust and better suited for harsh environments. The higher firing temperature limits the ability to integrate as many passive elements compared to LTCC, but HTCC excels in strength and reliability.

Because of these attributes, HTCC is commonly used in aerospace, defense, and industrial RF systems, where device resilience outweighs the need for ultra-thin construction. In terms of thinness, HTCC is less flexible than LTCC, but it remains valuable when performance must be guaranteed under extreme conditions.

Are Ultra-Thin Ceramic Films a Reality in RF Devices?

Beyond traditional substrates, researchers have explored ultra-thin ceramic films, sometimes under 50 µm in thickness. These films offer exciting potential for next-generation RF circuits, especially in wearable electronics and advanced communication systems. However, ultra-thin ceramics remain challenging to produce at scale due to their brittleness and handling difficulties.

Currently, such materials are mostly confined to laboratories or niche, high-cost applications. While they hint at future possibilities, most commercial RF devices rely on the proven practicality of alumina, AlN, LTCC, or HTCC substrates.

Comparison Table of Ceramic Substrates for RF Devices

|

Ceramic Material |

Minimum Thickness |

Key Advantages |

Typical RF Applications |

|

Alumina (Al₂O₃) |

0.1 mm (100 µm) |

Stable dielectric, cost-effective, strong |

Filters, oscillators, antennas |

|

Aluminum Nitride (AlN) |

0.15 mm |

High thermal conductivity, RF stability |

Power amplifiers, high-power RF circuits |

|

LTCC |

50–100 µm per layer |

Extreme miniaturization, 3D integration |

Smartphones, IoT modules, automotive radar |

|

HTCC |

~100 µm+ |

Mechanical strength, thermal endurance |

Aerospace, defense, harsh environment RF |

|

Ultra-thin films |

<50 µm |

Extreme compactness, research-level use |

Prototypes, experimental RF systems |

Ultimately, the choice of ceramic substrate balances several factors: thickness, dielectric stability, thermal management, and mechanical strength. As RF devices continue to evolve, thin ceramics—especially LTCC—will drive the development of smaller, faster, and more reliable communication systems.

At Best Technology, we provide alumina, AlN, LTCC, and HTCC ceramic solutions tailored for RF designs. Our certifications—ISO9001, ISO13485 for medical, IATF16949 for automotive, and AS9100D for aerospace—reflect our commitment to strict quality control and industry standards. With professional engineering support, MES-based traceability, and competitive pricing, we help customers achieve efficient and dependable RF performance.

If your RF project demands thin, high-performance ceramic substrates, Best Technology is ready to supply the right solution.

FAQs

1. What is the thinnest ceramic substrate available for RF devices?

In commercial use, alumina can reach 0.1 mm, AlN typically starts at 0.15 mm, and LTCC offers 50–100 µm per layer.

2. Why is LTCC popular for modern RF modules?

LTCC supports multiple ultra-thin layers with integrated components, making it ideal for compact devices like smartphones and IoT modules.

3. Can ultra-thin ceramic films below 50 µm be used in RF devices?

Yes, but they are mainly limited to experimental and research applications due to cost and fragility.

4. Which ceramic substrate is best for high-power RF applications?

Aluminum nitride is preferred for its excellent thermal conductivity, essential for power amplifiers and radar modules.

5. How can I select the right ceramic substrate for my RF project?

Consider the balance of thickness, thermal requirements, dielectric performance, and reliability. Best Technology engineers can provide expert guidance based on your application.

HOME

HOME