AlN Substrate Ceramic: Everything You Should Know

The AlN substrate has become one of the most important materials in modern electronic manufacturing. As devices continue to get smaller and more powerful, engineers face challenges related to heat buildup and reliability. Traditional materials like FR4 or alumina ceramics often struggle when placed under these extreme conditions. That’s where Aluminum Nitride ceramic steps in.

With its unique balance of high thermal conductivity, mechanical stability, and excellent insulation, AlN substrate plays a critical role in advanced applications. Whether in high-brightness LEDs, power modules, RF systems, or medical electronics, it provides the foundation for efficient, long-lasting devices.

In this article, we’ll look at what makes Aluminum Nitride ceramic different, its characteristics, why it is widely used in ceramic PCBs, and how it compares to Al2O3 substrates.

What is AlN Substrate?

An AlN substrate is a ceramic base material made from Aluminum Nitride, designed for electronic circuits that demand both thermal and electrical performance. It is often used in high-power and high-frequency devices, where efficient heat transfer is just as important as stable electrical insulation.

Unlike traditional organic laminates such as FR4, AlN substrates can handle high temperatures without losing performance. Its thermal conductivity ranges between 170 and 200 W/m·K, which is far higher than that of alumina or glass epoxy boards. This allows it to act as a heat spreader, protecting sensitive semiconductor devices.

Because of these properties, AlN substrates are considered premium solutions in industries where device reliability directly impacts safety, efficiency, and performance.

Features of Aluminum Nitride Ceramic

- With a range of 170–200 W/m·K, AlN conducts heat nearly as well as metals like copper but without sacrificing insulation.

- Despite its thermal performance, AlN is an excellent insulator. It maintains high resistivity even at elevated temperatures, allowing circuits to function without risk of shorting.

- The AlN dielectric constant falls between 8.5 and 9.0. This value offers a balance between insulation and frequency performance, so it is well-suited for RF and microwave applications.

- Its coefficient of thermal expansion (CTE) closely matches that of silicon. Which can reduces mechanical stress in semiconductor packaging and prevents cracks or failures during rapid heating and cooling.

- AlN ceramic has high hardness and structural integrity. It resists wear, making it suitable for components exposed to stress.

- It is chemically stable against most molten salts, gases, and common acids, ensuring long-term reliability even in harsh environments.

How Thick is the AlN Substrate?

The thickness of an AlN substrate depends on the specific application. Common values range from 0.25 mm to 1 mm, though custom options from 0.1 mm up to 2 mm are possible.

- Thin substrates (0.1–0.25 mm): Often used in RF modules and microwave circuits where compact design and signal efficiency matter.

- Standard substrates (0.38–1.0 mm): Suitable for LED boards, laser diodes, and high-power semiconductor packaging.

- Thicker substrates (1.0–2.0 mm): Used in heavy-duty power electronics, such as IGBT modules, where heat dissipation and structural strength are critical.

The choice of thickness is always a trade-off between thermal management, signal performance, and mechanical stability. Engineers usually determine the optimal thickness during the design stage based on simulation and testing.

Is AlN a Ceramic?

Yes, Aluminum Nitride is a ceramic. Its crystal structure belongs to the wurtzite type, which gives it exceptional thermal and dielectric properties. While traditional ceramics like alumina or zirconia are primarily valued for insulation and mechanical strength, AlN introduces thermal conductivity into the equation.

This makes it unique among engineering ceramics, as it provides the best of both worlds—heat transfer like a metal and insulation like a dielectric material. Because of this, AlN is classified as a high-performance or advanced ceramic.

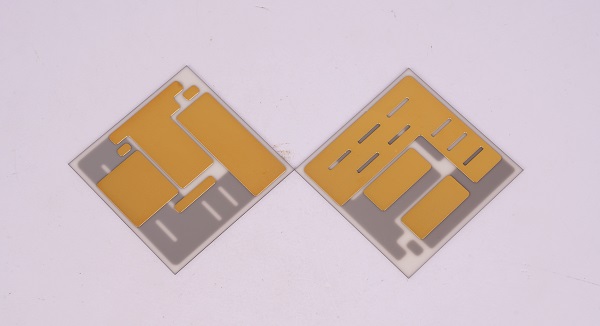

What Color is Aluminum Nitride?

Aluminum Nitride ceramics are usually light gray, pale beige, or off-white. The exact shade depends on purity and processing conditions. Compared to alumina, which often looks bright white, AlN has a slightly duller appearance.

While color itself doesn’t affect performance, it is often used as a quick identifier in manufacturing environments. Many engineers can distinguish AlN ceramic from Al2O3 ceramic by its subtle gray tone.

Why Choose AlN Substrate as Ceramic PCB Material?

The reason engineers choose AlN substrates for ceramic PCBs comes down to performance under demanding conditions.

- Superior Heat Management – High-power semiconductors generate significant heat. AlN transfers that heat away quickly, reducing the risk of thermal stress.

- High Reliability – Matching the CTE of silicon reduces mechanical failures in long-term use.

- Stable Electrical Properties – The AlN dielectric constant supports high-frequency applications while maintaining insulation.

- Durability – Resistance to wear, corrosion, and temperature cycling makes AlN PCBs last longer than many alternatives.

- Design Flexibility – Available in various thicknesses and can be metallized with copper, gold, or silver depending on circuit needs.

Because of these factors, AlN substrate is often chosen when performance matters more than cost. Industries like aerospace, defense, medical, and renewable energy rely on it to maintain system integrity.

AlN Ceramic PCB vs. Al2O3 Ceramic PCB

|

Property |

AlN Ceramic PCB |

Al2O3 Ceramic PCB |

|

Thermal Conductivity |

170–200 W/m·K (very high) |

20–30 W/m·K (much lower) |

|

Coefficient of Thermal Expansion (CTE) |

~4.5 ppm/°C (close to silicon) |

~7 ppm/°C (higher mismatch) |

|

Dielectric Constant |

8.5–9.0 (stable at high frequency) |

9.5–10.0 (slightly higher) |

|

Electrical Insulation |

Excellent |

Excellent |

|

Mechanical Strength |

High hardness, stable structure |

Strong but less thermal stability |

|

Cost |

Higher (premium material) |

Lower (cost-effective option) |

|

Typical Applications |

High-power devices, RF, aerospace, automotive, medical |

Consumer electronics, general-purpose devices |

In summary:

- If high thermal conductivity is a priority, aluminum nitride ceramic substrates have extremely high thermal conductivity and are suitable for heat dissipation of high-power density devices, such as 5G base stations and high-power lasers, while the thermal conductivity of alumina ceramic substrates is much lower.

- If cost is more sensitive, alumina ceramic substrates have a relatively lower cost and can be selected in some ordinary electronic devices with not extremely high performance requirements.

Applications of Aluminum Nitride Ceramics

- IGBT, MOSFET modules, rectifiers

- Microwave and RF packaging materials

- Laser diode (LD) and LED heat sinks

- Silicon wafer handling and processing

- Optoelectronic device substrates

- Chip carriers for sensors and detectors

- RF and microwave devices

- Automotive electronics

- Aerospace and Defense

- Medical Devices

Frequently Asked Questions

1. What is the dielectric constant of AlN?

The AlN dielectric constant is typically 8.5–9.0, stable across a wide range of frequencies.

2. Can AlN ceramic operate at very high temperatures?

Yes. It remains stable up to around 1000°C in inert environments.

3. Is AlN substrate environmentally safe?

Yes. It is non-toxic and considered safe for industrial and electronic applications.

4. How does AlN compare with BeO (beryllium oxide)?

Both have high thermal conductivity, but AlN is safer since BeO is toxic.

5. Can AlN substrates be customized?

Yes. Thickness, metallization, and surface finishing can all be tailored to application needs.

Until now, the AlN substrate has proven to be a game-changing material in advanced electronics. With its ability to combine high thermal conductivity, strong insulation, and mechanical durability, it offers solutions to challenges that traditional substrates cannot handle.

At BstceramicPCB, we produce high-quality AlN ceramic PCBs under strict standards, including ISO13485 for medical, IATF16949 for automotive, and AS9100D for aerospace. With over 19 years of experience in ceramic PCB manufacturing and as one of the leading PCB manufacturers, we support over 1,000 customers in different industrial areas worldwide. You can count on a PCB board manufacturer like us to meet your one-stop electronics manufacturing demands.

If your next project requires Aluminum Nitride ceramic substrates, our team can provide tailored solutions that deliver both performance and long-term reliability.

HOME

HOME