Alumina Board for Automobile Oil Level Sensor

In modern vehicles, sensors do more than just monitor performance—they protect engines, improve safety, and support predictive maintenance. Among these, oil level sensors play a crucial role. They continuously check the amount of oil in the engine or transmission and send alerts when the level drops too low. Without these sensors, engine components could run dry, leading to irreversible damage.

But oil level sensors operate in harsh conditions. They’re exposed to oil, vibration, heat, and sometimes pressure fluctuations. So the materials used in building these sensors must be incredibly reliable. This is where the alumina board comes in.

Also called an alumina substrate or Al2O3 substrate, this ceramic-based PCB has become a popular choice in automotive electronics, especially for sensor modules. Let’s explore what makes this material unique and why it’s a smart choice for oil level sensing systems.

What Is an Alumina Board?

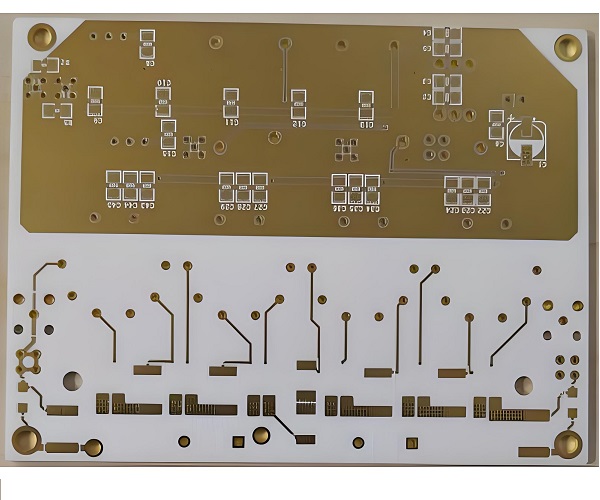

An alumina board is a type of printed circuit board made from aluminum oxide (Al2O3)—a ceramic material with exceptional thermal, mechanical, and electrical properties. It belongs to the category of ceramic PCBs and is also widely known as an alumina ceramic PCB.

The board starts with a base of sintered alumina, usually in purity levels of 96% or 99.6%. This ceramic layer acts as the dielectric. A layer of conductive copper is then bonded onto it using processes like Direct Bonded Copper (DBC) or Thick Film technology. After patterning and etching, the copper traces form the electrical circuit.

Key Features of Alumina Boards

- Thermal Stability: Alumina can tolerate continuous operation up to 250°C and brief exposure to even higher temperatures.

- Electrical Insulation: It has excellent dielectric strength, minimizing leakage or interference.

- Chemical Resistance: It resists oil, moisture, and corrosion.

- Mechanical Strength: The ceramic layer provides rigidity and vibration resistance.

- High Wear Resistance: Alumina is hard and doesn’t degrade under mechanical friction.

These properties make the Al2O3 substrate perfect for electronics that must survive in aggressive environments—like those found in the engine bay of a vehicle.

What Is an Automobile Oil Level Sensor?

An automobile oil level sensor measures how much oil is present in the engine, transmission, or oil reservoir. It sends real-time data to the vehicle's electronic control unit (ECU), which then informs the driver via dashboard indicators. Types of oil level sensors:

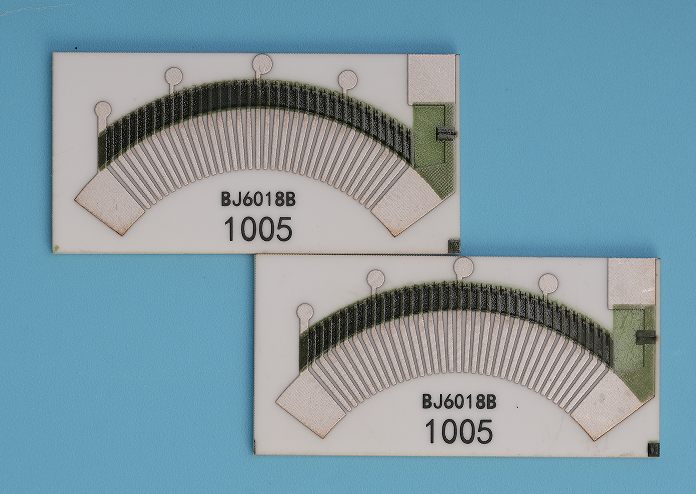

- Resistive Sensors: Measure oil level based on the change in electrical resistance.

- Capacitive Sensors: Use two conductive plates to detect the dielectric change as oil level varies.

- Ultrasonic Sensors: Emit sound waves and calculate oil level by analyzing the reflected wave.

Each of these sensor types needs a reliable PCB or substrate to house the electronics. In all cases, the environment is hostile—high temperatures, oil exposure, and constant movement. A weak PCB could degrade, leading to false readings or total sensor failure.

Why Alumina Board Is Suitable for Oil Level Sensors?

The alumina ceramic PCB excels in precisely the kind of environment where oil level sensors operate. Here’s why:

1. Withstands High Temperatures

Engines can get extremely hot. A typical PCB made of FR4 (epoxy fiberglass) begins to degrade at temperatures above 130°C. In contrast, alumina boards remain structurally stable beyond 250°C, which makes them suitable for long-term use inside engine bays.

2. Resists Oil and Chemicals

Inside an oil tank or engine compartment, the sensor is constantly exposed to lubricants, fuel vapors, and cleaning fluids. The alumina substrate is chemically inert and does not absorb these substances, unlike polymers that may swell or break down over time.

3. Superior Electrical Insulation

Oil sensors rely on accurate and uninterrupted signal transmission. Alumina provides excellent dielectric strength, meaning the circuits won't short-circuit even under high humidity or temperature changes.

4. Mechanical Durability

Vehicles vibrate—whether it's from engine operation, road bumps, or external impacts. The Al2O3 substrate maintains its structure and circuit integrity, preventing micro-cracks or warping.

5. Thermal Conductivity

Efficient heat dissipation is vital in compact sensor modules. Alumina offers good thermal conductivity, reducing the risk of heat-induced electronic failure.

Comparison with Other PCB Materials

Choosing a PCB material often comes down to balancing cost with performance. Here’s how the alumina substrate stacks up:

Alumina vs FR4

- Heat Resistance: Alumina outperforms FR4 in high-temperature environments.

- Moisture Absorption: FR4 tends to absorb moisture, reducing insulation. Alumina does not.

- Mechanical Strength: Alumina is more rigid but also more brittle than FR4.

- Cost: Alumina is more expensive but delivers better performance in the long run.

Alumina vs Metal Core PCBs (MCPCB)

- Thermal Conductivity: MCPCBs are good, but alumina still provides sufficient thermal dissipation for small sensor modules.

- Electrical Insulation: Alumina has better insulation properties.

- Environmental Resistance: Ceramic resists oil and chemicals better than metal cores.

In applications where size is limited and reliability is key, alumina boards have the edge.

Alumina Board Application in the Automotive Industry

Automakers are increasingly using alumina substrates in the following automotive sensor modules:

- Oil Level and Pressure Sensors

- Temperature Sensors (Coolant, Transmission)

- Exhaust Gas Recirculation (EGR) Sensors

- Airbag Detonation Control Units

- ABS and Brake Pressure Monitors

These sensors need to last the life of the vehicle without replacement. In EVs, where temperature rises rapidly in battery zones, alumina boards are now even used in battery management systems (BMS) for thermal monitoring.

Key Design Considerations When Using Alumina Board for Oil Sensors

While the alumina ceramic PCB offers many advantages, designers must consider a few key factors:

1. Brittleness

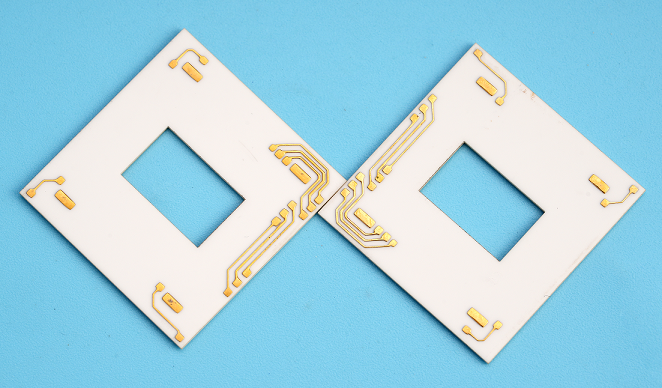

Ceramic is rigid but brittle. Avoid sharp corners or complex shapes in the PCB layout to reduce breakage risk during manufacturing or assembly.

2. Soldering Techniques

High-temperature solder paste is often required. Alternatively, conductive adhesives can be used to attach components.

3. Board Thickness

Standard thickness ranges from 0.25 mm to 1.0 mm. Thicker boards offer strength but increase material cost.

4. Trace Design

Copper traces must be bonded carefully to prevent peeling due to different thermal expansion rates. DBC (Direct Bonded Copper) or thick film methods help ensure better adhesion.

5. Encapsulation

Sensor assemblies must be coated or sealed to prevent oil from reaching exposed solder joints or connectors.

Working with a manufacturer that understands these ceramic-specific factors helps reduce risk and improve success rates.

Why Choose Best Technology for Alumina Oil Sensor PCBs?

Best Technology has more than 18 years of experience producing alumina ceramic PCBs for demanding applications. We work closely with automotive engineers to provide complete ceramic PCB solutions—from material selection to final testing. That’s why customers choose us:

- Material Expertise: We support 96% and 99.6% Al2O3 substrates, plus BeO and AlN for special thermal demands.

- Precision Processing: Laser cutting, DBC, and thick film technologies available.

- Certifications: ISO9001, IATF16949 for automotive, AS9100D.

- Customer Support: Fast feedback, DFM optimization, and one-on-one technical consulting.

- Professional PCB engineer for one-to-one service, drawing improvement & optimization.

- One-stop ceramic PCB making services, including ceramic pcb design, manufacturing, and assembly.

We don’t just sell ceramic PCBs—we help you make them perform.

FAQs

1. What is an alumina board used for in cars?

It’s commonly used in sensor modules like oil level, temperature, and exhaust sensors due to its resistance to heat and vibration.

2. What’s the difference between an alumina board and a standard PCB?

Alumina boards are ceramic-based and offer better thermal stability and insulation compared to FR4 or metal core PCBs.

3. Is Al2O3 substrate too brittle for automotive use?

No, when properly handled and designed, the mechanical strength of alumina is suitable for most sensor modules.

4. Are alumina ceramic PCBs more expensive?

Yes, but they offer a longer service life, especially in tough environments, which offsets the initial cost.

5. Can I get custom sizes or shapes?

Yes, Best Technology can provide custom sizes, hole patterns, surface finish options, and even hybrid stack-ups upon request.

HOME

HOME