What is Al2O3 Substrate? Al2O3 Substrate Price

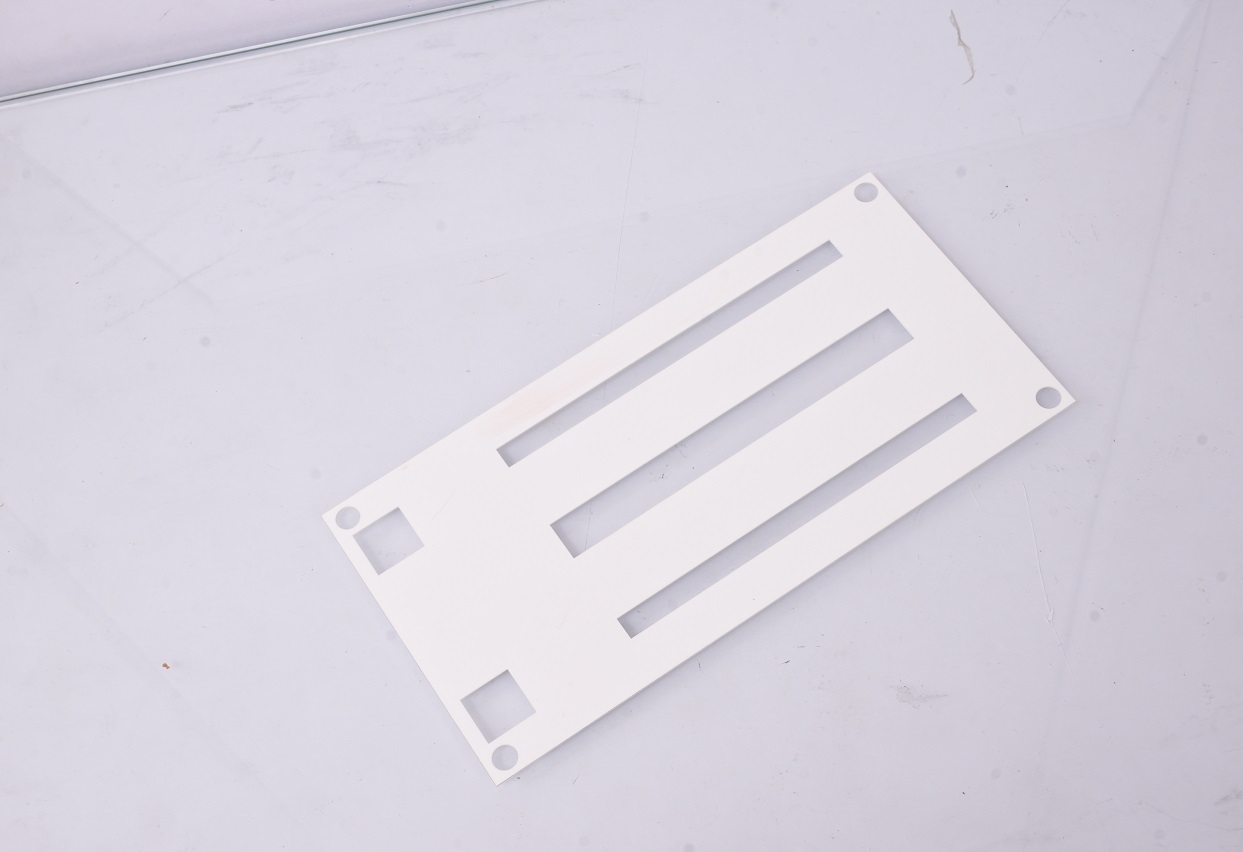

If you're working on high-performance electronics, you've likely come across Al2O3 substrates. These ceramic bases, made from aluminum oxide, have become a staple in advanced PCB manufacturing. They offer a blend of mechanical strength, thermal conductivity, and electrical insulation that's hard to match.

At BstCeramic PCB, we specialize in producing premium Al2O3 ceramic boards tailored for industries like automotive, aerospace, LED lighting, and power electronics. With certified quality systems and expert engineering support, we ensure reliability at every step — all while keeping Al2O3 substrate price competitive for global clients.

What Is Al2O3 Substrate?

Al2O3 substrate refers to a ceramic material made from aluminum oxide (Al₂O₃), commonly known as alumina. It's a widely used material in the electronics industry due to its strong insulation, mechanical strength, and ability to handle high temperatures. This makes it perfect for printed circuit boards (PCBs) in harsh or demanding environments.

Al2O3 substrates come in various purity levels, usually ranging from 96% to 99.6%. The higher the purity, the better the thermal and electrical performance, which is why different applications demand different grades.

How Thick Is Al2O3 Substrate?

The thickness of an Al2O3 substrate can vary depending on its intended use. Common thicknesses include:

- 0.25 mm

- 0.38 mm (commonly used)

- 0.5 mm

- 0.635 mm (commonly used)

- 1.0 mm

Custom thicknesses are also available. Thinner substrates are ideal for compact designs or multilayer stacks, while thicker options are preferred for enhanced mechanical strength or higher voltage insulation.

What Is the Difference Between Alumina and Silica?

Alumina (Al₂O₃) and Silica (SiO₂) are both ceramic materials, but they have very different properties and use cases. Below is a detailed comparison to help you better understand their differences:

|

Property |

Alumina (Al₂O₃) |

Silica (SiO₂) |

|

Thermal Conductivity |

20–30 W/m·K |

1–2 W/m·K |

|

Dielectric Strength |

High |

Moderate |

|

Electrical Insulation |

Excellent |

Good |

|

Thermal Expansion |

Moderate (~7–8 ppm/°C) |

Low (~0.5 ppm/°C for fused silica) |

|

Melting Point |

~2,072°C |

~1,710°C (fused silica) |

|

Mechanical Strength |

High (very hard and tough) |

Brittle and less tough |

|

Hardness |

~9 Mohs (very hard) |

~5.5–6.5 Mohs |

|

Chemical Resistance |

Resistant to most acids and alkalis |

Excellent resistance to most chemicals |

|

Cost |

Economical |

Varies (fused silica is more expensive) |

|

RF/Microwave Use |

Moderate |

High (especially low-loss fused silica) |

|

Common Applications |

PCBs, power electronics, LED modules |

Optical components, RF windows, insulators |

|

Manufacturing Availability |

Easily fabricated and widely available |

Less common in standard PCB substrates |

In a word, alumina is much stronger, more thermally conductive, and cost-effective. Silica, especially fused silica, is used in highly specific RF or optical applications where low thermal expansion and chemical purity are crucial.

Why Choose Al2O3 as Your Ceramic PCB Substrate?

There are several compelling reasons why engineers pick Al2O3 substrates for ceramic PCB designs:

- Excellent Electrical Insulation: Prevents current leakage even in high-voltage designs.

- Good Thermal Conductivity: Enables effective heat dissipation to avoid component overheating.

- Chemical Stability: Resistant to corrosion and oxidation.

- Cost-Effective: Compared to materials like AlN or Si₃N₄, Al2O3 offers good performance at a lower price.

- Wide Availability: Many manufacturers offer standardized sizes, making procurement easier.

At BstCeramic PCB, we use ISO-certified production processes and advanced inspection to ensure every Al2O3 board meets global standards for durability and electrical integrity.

How to Choose the Purity of Al2O3 Ceramic Substrate?

The purity of Al2O3 affects performance in terms of thermal conductivity, insulation, and mechanical strength. Here’s a basic guide:

- 96% Purity – Economical and suitable for general-purpose PCBs, it can meet almost demands.

- 99% Purity – Better electrical and thermal performance, used in more demanding environments.

- 99.6%+ Purity – High-end option for aerospace, RF modules, or medical devices.

When choosing the right grade, consider operating temperature, required voltage resistance, and cost limitations. BstCeramic PCB offers a wide range of purity levels and helps customers choose the right material based on project specifications.

Al2O3 Substrate Price

The Al2O3 substrate price varies depending on factors such as:

- Purity level (96%, 99%, or 99.6%)

- Substrate thickness

- Quantity and order size

- Surface finish or metallization type (Ag, Au, Cu, etc.)

- Precision or custom shapes

As of 2025, general prices range from $0.20 to $2.50 per square centimeter, depending on the factors above. For bulk orders or high-purity versions, prices may be adjusted accordingly.

BstCeramic PCB offers transparent pricing, fast prototyping, and flexible order quantities. We work closely with clients to meet both technical and budgetary goals.

Al2O3 vs. AlN Substrate: Properties & Applications

Al2O3 (Alumina) and AlN (Aluminum Nitride) are two of the most widely used ceramic materials for PCB substrates. Some customers don’t know how to choose between them. Here we listing a comparison table and showcase their best applications, hope this makes you sense.

|

Property |

Al2O3 (Alumina) |

AlN (Aluminum Nitride) |

|

Thermal Conductivity |

20–30 W/m·K |

170–200 W/m·K |

|

Dielectric Strength |

High |

Very High |

|

Electrical Insulation |

Excellent |

Excellent |

|

Coefficient of Thermal Expansion (CTE) |

~7–8 ppm/°C |

~4.5 ppm/°C (closer to silicon) |

|

Mechanical Strength |

Very strong |

Stronger and more resistant to cracking |

|

Operating Temperature Range |

Up to 1,500°C |

Up to 1,000°C (with better heat transfer) |

|

Thermal Shock Resistance |

Moderate |

High |

|

RF Loss |

Moderate (not ideal for RF) |

Low (excellent for high-frequency) |

|

Chemical Resistance |

Excellent |

Moderate to high |

|

Availability & Fabrication |

Widely available, easy to process |

More complex fabrication, fewer suppliers |

|

Cost |

Lower |

Higher (2–4 times Al₂O₃) |

|

Weight |

Slightly heavier |

Lighter |

|

Surface Finish Options |

Ag, Au, Cu, Ni/Au |

Similar options available |

|

Applications |

LED lighting, automotive, general PCBs |

Power modules, RF amplifiers, military systems |

Application Suitability:

|

Application Type |

Better Choice |

Why? |

|

General Purpose PCB |

Al2O3 |

Cost-effective and strong |

|

High-Power Electronics |

AlN |

Better heat dissipation |

|

RF/Wireless Modules |

AlN |

Lower RF loss and matching CTE to silicon |

|

Automotive Electronics |

Al2O3 or AlN |

Depends on power and heat levels |

|

LED Boards |

Al2O3 |

Good thermal performance at lower cost |

|

Military/Aerospace |

AlN |

Thermal shock resistance + electrical specs + excellent heat dissipation |

Your Best Al2O3 Ceramic PCB Manufacturer – BstCeramic PCB

Choosing the right supplier matters just as much as picking the right material. BstCeramic PCB is your reliable partner for Al2O3 substrate-based PCBs, offering:

- Customized sizes and thicknesses

- Metallization options: Ag, Au, Cu, Ni/Au

- CNC machining and laser cutting

- Strict QC system

- Online tracking for every process step

Our factory in Shenzhen is equipped with modern facilities for thick film, DBC, and DPC ceramic board production. Whether you're prototyping or scaling to volume production, we ensure on-time delivery and consistent quality.

Frequently Asked Questions (FAQs)

1. What industries use Al2O3 ceramic PCBs?

They are widely used in automotive electronics, LEDs, power supplies, RF modules, medical devices, and aerospace.

2. Can I request a custom shape or drill pattern?

Yes. BstCeramic PCB offers custom machining including V-cuts, vias, and complex outlines.

3. How fast can you deliver Al2O3 PCBs?

Prototypes typically take 5–7 working days. Volume orders depend on design complexity and order size.

4. Do you support metallization with gold or silver?

Absolutely. We offer Ag, Au, Ni/Au, and Cu metallization for various applications.

5. What’s the minimum order quantity (MOQ)?

We support low-volume prototypes as well as mass production. There’s no strict MOQ for most designs.

HOME

HOME