How Much Does an Alumina Sheet Cost? | Alumina Sheet Prices 4x8

Alumina sheet price is a major concern for engineers and purchasing teams sourcing ceramic substrates for high-performance electronics. These sheets, made of aluminum oxide (Al₂O₃), are widely used for their excellent thermal conductivity, electrical insulation, and wear resistance. Whether you're buying for industrial use or for manufacturing alumina ceramic PCBs, understanding current pricing and influencing factors is essential.

In this article, we’ll explore the standard alumina sheet sizes, market prices (including alumina sheet prices 4x8), and how these materials transition into ceramic circuit boards. We'll also introduce how Best Technology supports global customers in producing top-quality alumina ceramic PCBs.

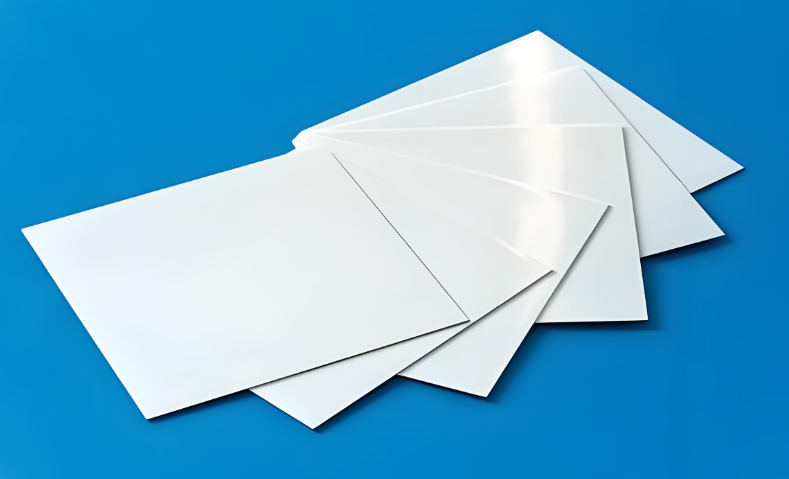

What Is an Alumina Sheet and Why Is It Widely Used?

An alumina sheet is a flat, solid plate made from sintered aluminum oxide (al2o3) ceramic. Its hardness, corrosion resistance, and insulation properties make it a favorite for industries like electronics, aerospace, medical devices, and power modules.

Depending on its purity level—typically ranging from 95% to 99.6%—alumina can withstand temperatures over 1500°C while providing excellent dimensional stability. Many customers initially purchase alumina sheets as raw material for insulation layers or protective components. However, increasingly, these sheets are being adapted as substrates for high-performance PCBs, especially in LED and RF applications.

Standard Alumina Sheet Sizes and Prices

When sourcing alumina sheets, one of the most commonly requested formats is the 4x8 feet (approximately 1220mm x 2440mm) sheet. This large-format size offers flexibility in cutting smaller parts or fabricating multiple PCBs from a single sheet.

Here’s a rough breakdown of typical pricing in the current market:

|

Alumina Type |

Size |

Thickness |

Approx. Price (USD) |

|

95% Alumina |

4x8 ft |

3mm |

$120 – $250 |

|

99% Alumina |

4x8 ft |

1–3mm |

$150 – $280 |

|

99.6% Alumina |

4x8 ft |

1–2mm |

$180 – $320 |

Please remember that these are reference prices. Actual cost may vary depending on your order quantity, required tolerances, surface treatment (polished vs. raw), and shipping destination.

What Factors Affect Alumina Sheet Price?

Several variables impact the final price of alumina sheets:

- Purity Level

Higher purity materials (e.g., 99.6%) require more controlled processes and refined powders, which increase cost.

- Sheet Dimensions and Thickness

Thicker sheets or custom sizes beyond standard dimensions typically cost more due to higher material usage and machining difficulty.

- Surface Finish

Polished or ground surfaces are more expensive than raw finishes due to added labor and precision requirements.

- Customization

If you require drilled holes, slots, or special shapes, custom CNC machining will add to the cost.

- Quantity Ordered

Bulk orders benefit from volume pricing, while small-lot orders might include setup or tooling fees.

- Origin and Supplier

Alumina sourced from China or India may be more cost-competitive than those made in the US or Germany. However, supplier capabilities, quality control, and certifications should always be considered.

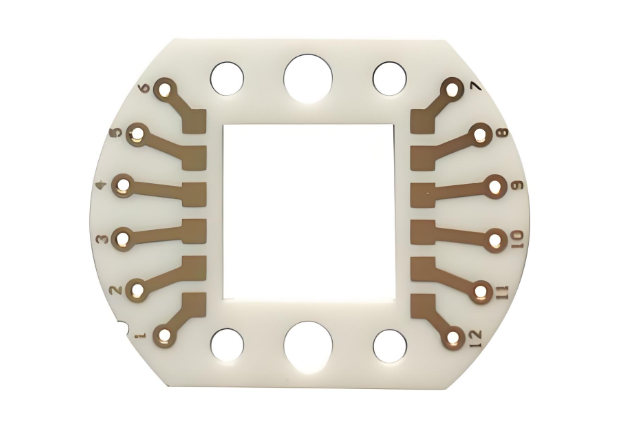

Alumina Sheet vs. Ceramic PCB

Alumina sheets aren’t just for insulation or mechanical support—they also serve as the foundation for ceramic PCBs, which are essential in demanding electronic environments. These PCBs are built by applying conductive metal layers (often copper, silver, or gold) onto alumina substrates using thick film, DBC (Direct Bonded Copper), or DPC (Direct Plated Copper) technologies.

For example, alumina ceramic PCBs are often found in:

- LED lighting systems

- Power electronics modules

- High-frequency radar circuits

- Medical sensors and imaging systems

- Military-grade RF components

Why alumina? Because its combination of thermal conductivity (~24 W/m·K), high breakdown voltage, and dimensional stability under thermal cycling makes it a superior base material compared to FR4 or metal-core boards.

Alumina Ceramic PCB: How It Works and Where It’s Used

Alumina ceramic PCBs consist of an alumina substrate bonded with conductive metal traces. These boards are capable of withstanding high temperatures and rapid power cycling, making them ideal for high-reliability applications.

Typical alumina ceramic PCB stack-ups include:

- Substrate: 96% or 99.6% alumina

- Copper Trace Layer: Copper (in DBC or DPC) or silver-palladium (in thick-film)

- Surface Finish: ENIG, silver plating, or bare copper depending on the application

Because of their robust structure and excellent dielectric strength, these PCBs are often used in industries where conventional PCBs would fail.

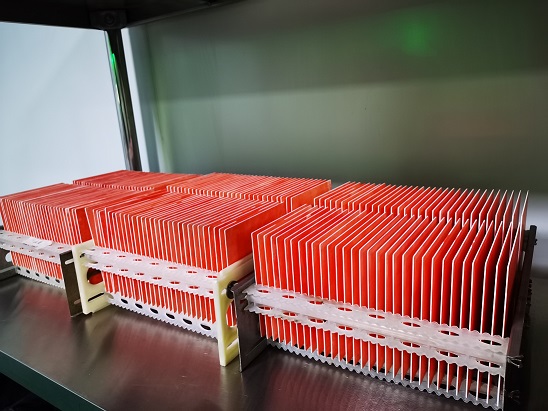

Best Technology: Expert in Alumina Ceramic PCB Manufacturing

If you're looking for a reliable partner to turn alumina sheets into high-quality ceramic PCBs, Best Technology is your go-to manufacturer. We specialize in alumina ceramic PCB production and have extensive in-house capabilities to support both standard and customized requirements. Here are why our customers choose us:

- Various materials options: We work with 96% and 99.6% alumina and offer guidance on selecting the right purity for your project.

- Complete Process Control: From substrate cutting, hole drilling, metal deposition, and laser structuring to plating and final inspection.

- Tight Tolerance Manufacturing: Machining accuracy within ±0.02mm, suitable for precision sensor or LED modules.

- Global Support: Fast prototyping and batch production with export to North America, Europe, and Asia.

- One-stop service from raw material choosing, ceramic PCB fabrication to ceramic PCB assembly.

- DPC, DBC, thick film, thin film, AMB, HTCC and LTCC ceramic PCB available.

Whether you need 4x8 raw alumina sheets or fully processed ceramic PCBs, Best Technology offers reliable pricing, engineering support, and global delivery.

How to Request a Quote for Alumina Sheet or Alumina Ceramic PCB?

To get an accurate quote for alumina sheet or ceramic PCBs, please prepare the following:

- Desired purity level (e.g., 96%, 99%, 99.6%)

- Sheet size and thickness

- Quantity needed (sample or bulk)

- For PCBs: Gerber files or design drawings

- Any special requirements: holes, slots, plated vias, metal thickness, etc.

We recommend contacting our team directly to ensure your application is fully supported.

HOME

HOME