What Factors Affect the Cost of Your Ceramic Circuit Board?

When choosing ceramic circuit boards for your application, cost is always an important consideration. Ceramic PCBs offer excellent thermal conductivity, mechanical strength, and high-frequency performance—but these benefits can come at a higher price compared to traditional FR4 boards. So, what exactly drives the cost of a ceramic circuit board? Let’s break it down so you can make informed decisions when budgeting your next project.

Type of Ceramic Material Used

The ceramic substrate itself is one of the biggest factors affecting the overall price. Not all ceramics are created equal. The type of material you choose will depend on your application's needs, but it also impacts your budget significantly.

- Alumina (Al₂O₃) is the most commonly used ceramic material. It’s relatively inexpensive, widely available, and offers decent thermal conductivity and electrical insulation. If your application doesn’t require extreme heat dissipation, Alumina is a budget-friendly choice.

- Aluminum Nitride (AlN), on the other hand, has much better thermal conductivity—up to ten times that of Alumina—but it comes at a higher cost. It’s ideal for applications where heat dissipation is critical, such as power modules or LEDs.

- Beryllium Oxide (BeO) provides even greater thermal performance, but it’s highly expensive and difficult to handle due to its toxicity. BeO is typically used only in very specialized, high-end applications like aerospace or military systems.

Choosing the right ceramic material based on your performance needs can help you control costs without sacrificing reliability.

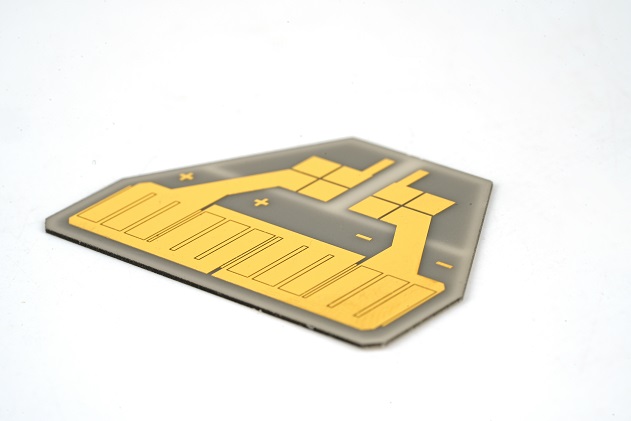

Board Thickness and Size

The thickness and size of the board play a key role in pricing. Simply put, larger boards require more raw material and more machine time, which directly translates into higher costs.

Similarly, thicker substrates offer better mechanical support and heat spreading, but they increase both material usage and processing time. Some applications may require boards as thin as 0.25mm, while others might go over 2.0mm for added durability.

Also, custom sizes or irregular shapes may involve additional tooling costs. If your design deviates from standard panel dimensions, it could reduce manufacturing efficiency and increase scrap, which ultimately affects your cost per piece.

Metallization Type and Thickness

Ceramic circuit boards use different types of metal conductors, and the choice of metal has a major impact on cost. This is especially true for boards manufactured using thick film or direct copper bonding technologies.

- Silver (Ag) is common in thick film ceramic PCBs because of its low resistivity and easy processing. However, it’s prone to migration under humid conditions, which may not be suitable for all environments.

- Copper (Cu) is widely used in DBC (Direct Bonded Copper) and DPC (Direct Plated Copper) ceramic PCBs. Copper offers excellent conductivity and heat performance, but the cost goes up when thick copper layers are needed—especially for high-power circuits.

- Gold (Au) or platinum (Pt) are used in specialty applications where corrosion resistance and reliability are critical. These metals significantly increase the price and are generally used in aerospace, defense, or medical electronics.

Metallization thickness also matters. Thicker traces mean more metal consumption and longer sintering times, which affects overall production cost.

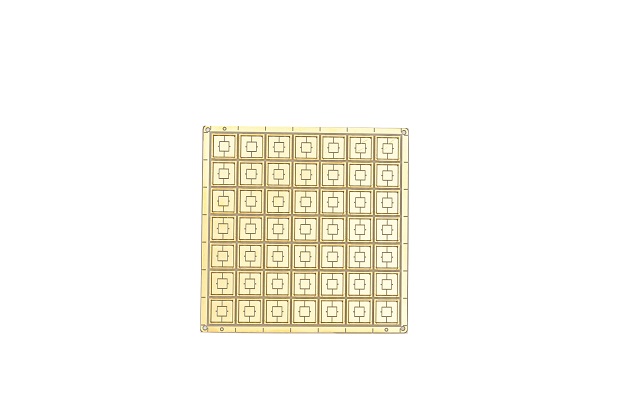

Circuit Complexity of Ceramic PCB

Not all circuit designs are created equal. A simple single-sided board is far more affordable than a multi-layer, densely routed circuit.

If your design includes multiple layers, microvias, or fine line widths, it will take longer to manufacture and may involve more advanced equipment and processing steps. Complex routing often requires laser drilling, sequential lamination, or multilayer ceramic technologies like LTCC (Low-Temperature Co-fired Ceramic).

These steps require precision and can reduce manufacturing yield, meaning more boards must be scrapped or reworked—costs that inevitably get passed on to the customer.

To manage costs, try to simplify your layout where possible and discuss design optimization options with your manufacturer.

Production Volume

Like most manufacturing processes, ceramic PCB pricing follows the rule of economies of scale: the more you produce, the lower the cost per unit.

For small orders or prototyping, setup and tooling costs can’t be spread across many units, making the price per piece relatively high. This includes the cost of screens, masks, stencils, and machine calibration.

However, when you order in bulk, those fixed costs are distributed across a larger number of boards, which brings the unit cost down considerably.

If you’re in the early stages of development, consider ordering small batches for testing, and then move to volume production to take advantage of better pricing.

Surface Finishing and Coatings

Surface finishes protect the metal traces from oxidation and improve solderability during assembly. While necessary, these finishes do add to the total cost of your ceramic PCB.

Common options include:

- ENIG (Electroless Nickel Immersion Gold): Provides excellent flatness and corrosion resistance, but it’s more expensive.

- OSP (Organic Solderability Preservative): A lower-cost option that works well for simple assemblies but has a shorter shelf life.

- Electroplated Gold: Used for edge connectors or wire bonding applications, but it’s pricey.

In addition to finishes, some boards require special protective coatings or solder masks—though ceramic substrates often skip solder masks due to their heat resistance. If your application needs special surface treatments, expect those to be reflected in the cost.

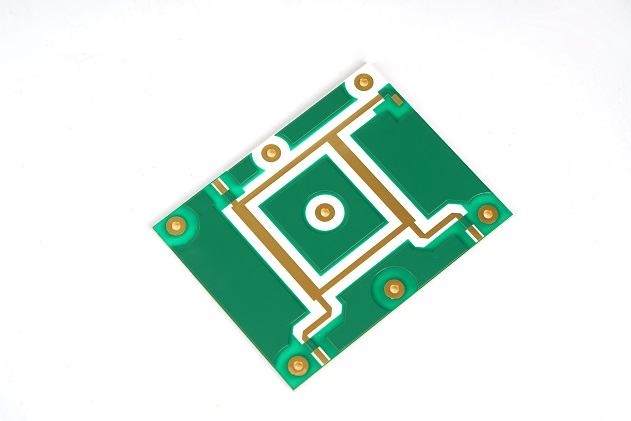

Type of Ceramic PCB Process

There are several methods for manufacturing ceramic PCBs, and the process you choose will influence the price significantly.

- DBC (Direct Bonded Copper) involves bonding thick copper directly onto the ceramic surface using a high-temperature process. It provides strong adhesion and excellent thermal performance but is more expensive due to the material and equipment involved.

- DPC (Direct Plated Copper) uses sputtering and electroplating to apply copper. It allows for finer lines and better precision but has higher processing costs.

- LTCC (Low-Temperature Co-fired Ceramic) and HTCC (High-Temperature Co-fired Ceramic) are used for multilayer circuits. These processes involve stacking and co-firing multiple ceramic layers. They’re suitable for compact, high-density circuits but are complex and costly.

The right process depends on your application’s thermal, electrical, and size requirements, so it’s best to consult with a knowledgeable manufacturer early in your design phase. For more information about ceramic PCB metallization process, please view our another post:

Tolerance and Yield Requirements

If your project demands tight tolerances—whether for hole diameters, trace widths, or alignment—expect to pay more. Holding tighter tolerances requires advanced equipment, meticulous quality control, and sometimes multiple inspection stages.

In industries like aerospace, medical, or automotive, high reliability is non-negotiable. That means every board has to pass stringent testing standards, such as 100% electrical testing, AOI (Automated Optical Inspection), or X-ray inspection.

Tighter requirements reduce manufacturing yield, meaning more boards are rejected or need rework, which drives up the overall cost.

Post-Processing Needs

Some ceramic PCBs require additional steps after basic fabrication to meet specific design or application needs. These post-processing services can include:

- Laser cutting or trimming for precise board outlines

- Polishing to smooth surfaces or edges

- Drilling or cavity machining for custom mechanical features

- Solder paste application for assembly-ready finishes

Every added step involves labor, machine time, and sometimes custom jigs or tools. If your design includes non-standard features, it’s important to factor these costs into your budget.

Whether it’s selecting the right ceramic material, simplifying your circuit, or planning for volume production, cost-saving opportunities are everywhere—especially when you work with an experienced partner.

At Best Technology, we don’t just build ceramic boards—we help you design them for success. From material selection to final testing, our engineers are here to support your project with quality you can trust and prices you can justify.

Need a Quote for Your Ceramic PCB?

Share your drawings or specifications with us, and our team will provide a fast, accurate quote. We’ll even offer suggestions to help reduce cost while improving performance.

HOME

HOME