Ceramic PCBs Essential Benefits and Applications

Ceramic pcbs are special in electronics. They use ceramic materials. These materials help control heat very well. They also stop electricity from leaking. Engineers like ceramic because it is strong. It works well in tough places. These boards are used in many things. They help power electronics, cars, LED lights, planes, telecom, medical devices, and green energy. Ceramic substrates like alumina and aluminum nitride work well. They do not get damaged by chemicals. They can handle very hot or cold temperatures. Every ceramic pcb is tough and works well for new electronics.

Key Takeaways

- Ceramic PCBs are very good at handling heat. They help electronics stay cool. This makes electronics last longer.

- These boards stop electricity from leaking. This makes them great for high-voltage uses.

- Ceramic PCBs are tough and strong. They can handle hard conditions in cars and planes.

- Their chemical stability helps them work well in tough places. This means they need less fixing.

- Ceramic PCBs help make things smaller. This lets us have tiny and better electronic devices.

Key Benefits of Ceramic PCBs

Thermal Management

Ceramic pcb boards are great at handling heat. Ceramic materials like aluminum oxide and aluminum nitride move heat fast. They have high thermal conductivity, often over 100 W/mK. This helps heat leave important parts quickly. Devices that use a lot of power need ceramic pcb boards to stay cool. When heat is managed, electronics last longer and work better.

- Ceramic substrates keep electricity separate and move heat well.

- Good thermal management stops devices from getting too hot.

- High thermal conductivity helps power electronics and LED lights work smoothly.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Aluminum Nitride | 170-220 |

| Alumina | 20-30 |

| IMS PCB | ~10 |

Electrical Insulation

Ceramic pcbs are very good at stopping unwanted electricity. Ceramic materials block extra currents and protect circuits. This makes ceramic pcb boards perfect for high-voltage and sensitive electronics.

- Ceramic substrates are strong insulators, better than metal ones.

- High thermal conductivity lets heat out but keeps electricity paths apart.

- Ceramic pcbs can handle high temperatures, so they work in tough places.

Mechanical Strength

Ceramic pcb boards are strong and hard to break. Ceramic materials do not bend easily and are very tough. These features help ceramic pcbs survive shaking, bumps, or stress in cars and planes.

- Ceramic pcb boards can handle shocks, wear, and chemicals.

- Strong boards work well where there is lots of vibration.

- Tough ceramic pcbs last longer and do not break easily.

Tip: Engineers pick ceramic pcb boards for cars and planes because they last longer and need fewer fixes.

Dielectric Performance

Ceramic pcbs are great at storing and separating electrical charges. Ceramic materials have a high dielectric constant. This helps in circuits that need to send signals fast, like RF applications.

- Ceramic pcb boards help signals stay clear and strong.

- Good dielectric performance means less signal loss and noise.

- Ceramic substrates let engineers print traces directly, making electronics better.

Miniaturization & Density

Ceramic pcb boards help make small and light devices. They can hold tiny traces and parts. This lets engineers build smaller gadgets that still work well.

- Ceramic pcbs allow tight layouts for new electronics.

- Small size helps in medical tools, telecom, and portable devices.

- Ceramic pcb boards fit more features in less space.

Chemical Stability

Ceramic pcb boards do not get ruined by chemicals or water. Ceramic materials do not react with acids, bases, or solvents. This makes ceramic pcbs work well in harsh places.

- Ceramic pcb boards keep working even with chemicals or moisture.

- Good chemical stability means less fixing and replacing.

- Ceramic pcb boards last longer in factories and outside.

Note: Ceramic pcbs are used in green energy and medical devices because they stay strong in hard conditions.

Ceramic pcb boards mix high thermal conductivity, electrical insulation, strength, and chemical stability. These features make ceramic pcbs the best choice for powerful and tough electronics. Ceramic pcb manufacturing keeps getting better, so engineers can make reliable and smart systems.

Applications of Ceramic PCBs

Power Electronics

Ceramic pcb boards are important in power electronics. Engineers pick ceramic pcb boards for high-power jobs. Ceramic materials move heat away fast and block electricity well. These boards do not bend or rust, so they work in tough places. The table below shows how ceramic pcb boards help:

| Performance Improvement | Description |

|---|---|

| High Thermal Conductivity | Ceramic pcb boards move heat better. Alumina cools 50 times faster than FR4 pcb. |

| High Mechanical Strength | Ceramic pcb boards do not break from heat or chemicals. |

| Low Dielectric Loss | Ceramic pcb boards keep low dielectric constant and dissipation factor, even when hot or at high frequency. |

Automotive Systems

Ceramic pcb boards help cars by handling shaking, heat, and chemicals. Ceramic pcb manufacturing makes boards that last longer and need less fixing. These boards can take high voltage and work well in engine controls and sensors.

LED & Lighting

Ceramic pcb boards make LED lights better. Ceramic materials connect to heat sinks, so heat leaves quickly. This helps LEDs last longer and work better.

- Ceramic pcb boards move heat away from LEDs.

- Engineers use ceramic pcb boards to design LED parts that control heat.

| Evidence | Explanation |

|---|---|

| Ceramic base with thermal heat sink | Ceramic pcb boards help LEDs get rid of heat. |

| Superior heat dissipation properties | Ceramic pcb boards cool better than old ways. |

Telecom & RF Circuits

Ceramic pcb boards work well in telecom and RF circuits. Ceramic materials have low and steady dielectric constant, low loss tangent, and controlled thermal expansion. These things help signals stay strong and clear.

| Characteristic | Ceramic PCBs | Standard FR-4 PCBs |

|---|---|---|

| Dielectric constant (Dk) | Low and steady | Changes more |

| Loss tangent (Df) | Low | Higher |

| Coefficient of thermal expansion (CTE) | Controlled | Not controlled |

| Impedance for high-speed signals | Lower impedance | Higher impedance |

Aerospace & Defense

Ceramic pcb boards meet tough rules in aerospace and defense electronics. Ceramic pcb manufacturing makes boards that can handle very hot and cold and lots of shaking. Military products need to work all the time, and ceramic pcb boards do that.

| Evidence Type | Description |

|---|---|

| Reliability Standards | Military products need to be very reliable. |

| Application Context | Aerospace and defense electronics need high reliability. |

Biomedical Devices

Ceramic pcb boards help medical devices by staying strong against chemicals and working well at high frequencies. Ceramic materials do not get ruined by water or chemicals, so they are good for medical sensors and imaging tools.

Other Uses

Ceramic pcb boards are used in special jobs. SRAM memory modules use multi-layer ceramic pcb for strong and packed assembly. Missile and radar transmission modules use aluminum nitride for fast heat movement. LTCC pcb makes analog and digital circuits smaller and lighter.

| Application Area | Description |

|---|---|

| SRAM Memory Module | Multi-layer ceramic pcb for strong and packed assembly. |

| Missile and Aerospace Products | Made for tough places, showing strength. |

| Radar Transmission Module | Aluminum nitride moves heat fast. |

| Analog/Digital PCB | LTCC pcb makes circuits smaller and lighter. |

Ceramic pcb boards are used in many high-performance jobs. Ceramic pcb manufacturing keeps getting better, helping with high-frequency, high-power, and important tasks.

Ceramic PCB Boards: Types & Manufacturing

Substrate Materials

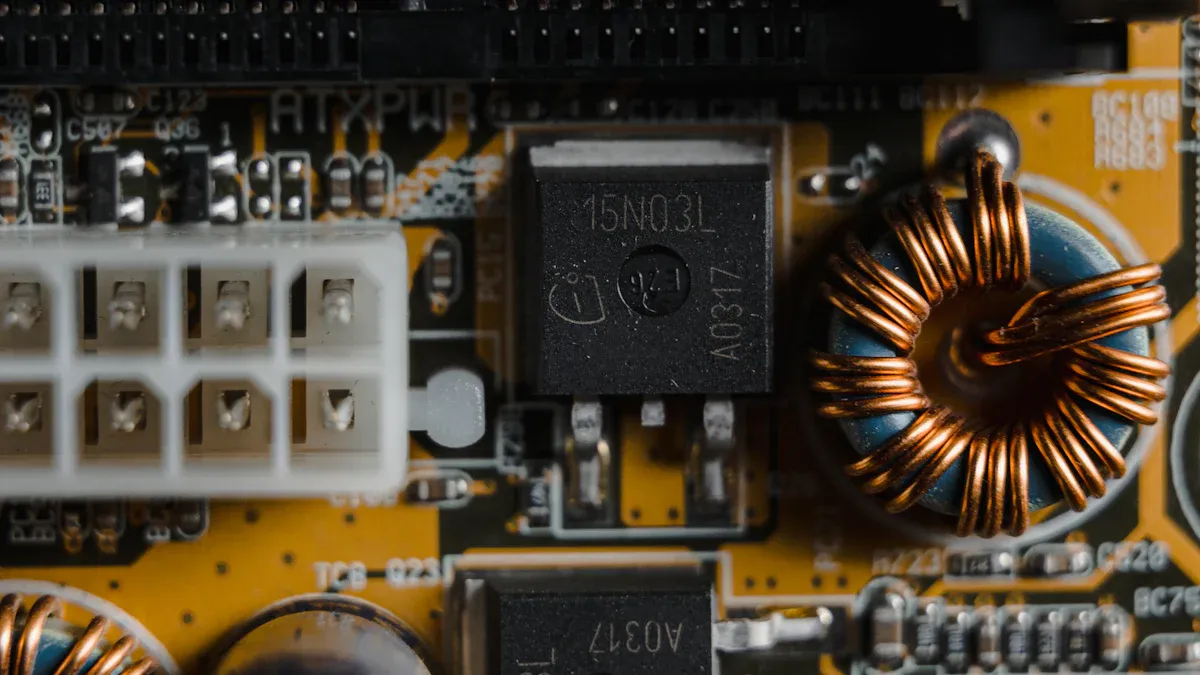

Ceramic pcb boards use different ceramic substrates. Each type has special features for certain jobs. Aluminum nitride moves heat well and is very strong. Aluminum oxide, called alumina, stops electricity and moves heat okay. It costs less. Diamond, zirconia, and silicon nitride are also used. These are not common because they cost more or are needed for special jobs. The table below lists the main features of popular ceramic substrates:

| Material | Thermal Conductivity (W/m·K) | Advantages | Applications |

|---|---|---|---|

| Aluminum Nitride (AlN) | 170-320 | Moves heat well, does not expand much, strong | Power modules, car electronics, LED lights |

| Aluminum Oxide (Al2O3) | 15-35 | Costs less, stops electricity, moves heat okay | Communication electronics, voltage sensors, inverters |

Ceramic pcb boards with aluminum nitride work best in high temperature designs. Alumina is good for low temperature and multilayer ceramic pcb boards.

Manufacturing Methods

Ceramic pcb boards are made in different ways. Engineers pick the method based on what the board needs to do. High temperature co-fired ceramic (HTCC) heats boards above 1600°C. This makes them strong. Low temperature co-fired ceramic (LTCC) uses heat below 900°C. It lets engineers make complex and multilayer boards. Direct bonded copper (DBC) sticks copper to ceramic for great heat control. Direct plated copper (DPC) puts copper right on ceramic to help heat move better. Thick and thin film methods print lines on ceramic for custom designs.

| Manufacturing Method | Characteristics | Applications |

|---|---|---|

| LTCC | Layers pressed below 900°C, makes complex circuits | Communication electronics, car sensors |

| HTCC | Made above 1600°C, very strong | Aerospace, military electronics |

| DBC | Copper joined to ceramic with heat, cools well | Power inverters, high-power devices |

| DPC | Copper put on ceramic, moves heat well | High-power LED lights |

Tip: Engineers pick the making method based on how much heat, electricity, and strength the board needs.

Performance Impact

Ceramic pcb boards work well and last long because of their materials and how they are made. Boards with aluminum nitride and DBC or DPC methods handle lots of power and heat. LTCC and HTCC let engineers make multilayer boards for packed and tricky circuits. Ceramic pcb boards do not get ruined by chemicals or stress. This makes them good for tough places. Ceramic pcb manufacturing keeps getting better, helping new uses in power electronics, cars, and medical tools.

Ceramic pcbs are great at moving heat, stopping electricity, and staying strong. Engineers use ceramic pcb boards for hard jobs where regular pcb boards cannot work.

Limitations & Considerations

Cost Factors

Ceramic pcb boards have many good points, but they usually cost more than regular pcb boards. The price is higher because ceramic materials are expensive. Making these boards also needs more steps. Using high-purity ceramic substrates like aluminum nitride and special bonding methods makes the cost go up. Companies need to think about these costs when they want their products to last a long time and work well. For big projects, ceramic pcb boards can make the budget bigger. Engineers pick ceramic pcb boards when the need for good heat control and strength is worth the extra money.

| Factor | Impact on Cost |

|---|---|

| Ceramic material type | High-purity costs more |

| Manufacturing method | Advanced steps add cost |

| Board complexity | More layers, higher price |

Size & Layer Limits

Ceramic pcb boards cannot be too big or have too many layers. The ceramic substrate can break if the board is too large. Most ceramic pcb boards work best when they are small or medium. Multi-layer ceramic pcb boards can be made, but adding layers makes things harder and costs more. Designers need to make sure their layouts fit the limits of ceramic technology. Big or thick boards may not be as strong or last as long as smaller ones.

Fragility

Ceramic pcb boards are tough in hard places, but the ceramic material can break easily. People must be careful when handling and putting these boards together. If the protective layer cracks, the board can stop working later. Water and dirt can cause problems with electricity. Ceramic capacitors do not fix themselves like some other types. Engineers need to handle and pack ceramic pcb boards carefully to keep them strong and reliable. Fragility is important when moving and installing these boards.

Safety Notes

Ceramic pcb boards use different ceramic materials, and some need special safety steps. For example, beryllium oxide (BeO) moves heat well, but its dust is dangerous to breathe. Workers must follow safety rules when working with BeO ceramic pcb boards. Most ceramic pcb boards use safer materials like alumina and aluminum nitride. Companies should always check safety sheets and teach workers how to handle materials safely. Safety is important when making and using ceramic pcb boards.

Note: Picking the best ceramic pcb board means thinking about cost, size, strength, and safety. Good planning helps make sure the boards work well and last a long time in tough jobs.

Ceramic pcb controls heat well and keeps electricity safe. It is also very strong. Engineers use ceramic pcb in many fields. These include power electronics, cars, LED lights, planes, telecom, and medical devices. Ceramic pcb works well in tough places and in systems that need high performance. It is reliable and lasts a long time when other boards do not. Ceramic pcb is good for projects that need heat control and long life. It can cost more, but the good points are worth it. You need to handle and design ceramic pcb carefully. Ceramic pcb helps new technology work better. It helps different industries get better. Ceramic pcb makes products safer. It keeps things working without problems. Ceramic pcb gives good results. Ceramic pcbs fit what people need today. If you want a special ceramic pcb, you can ask for help by using the website’s contact form or email.

HOME

HOME