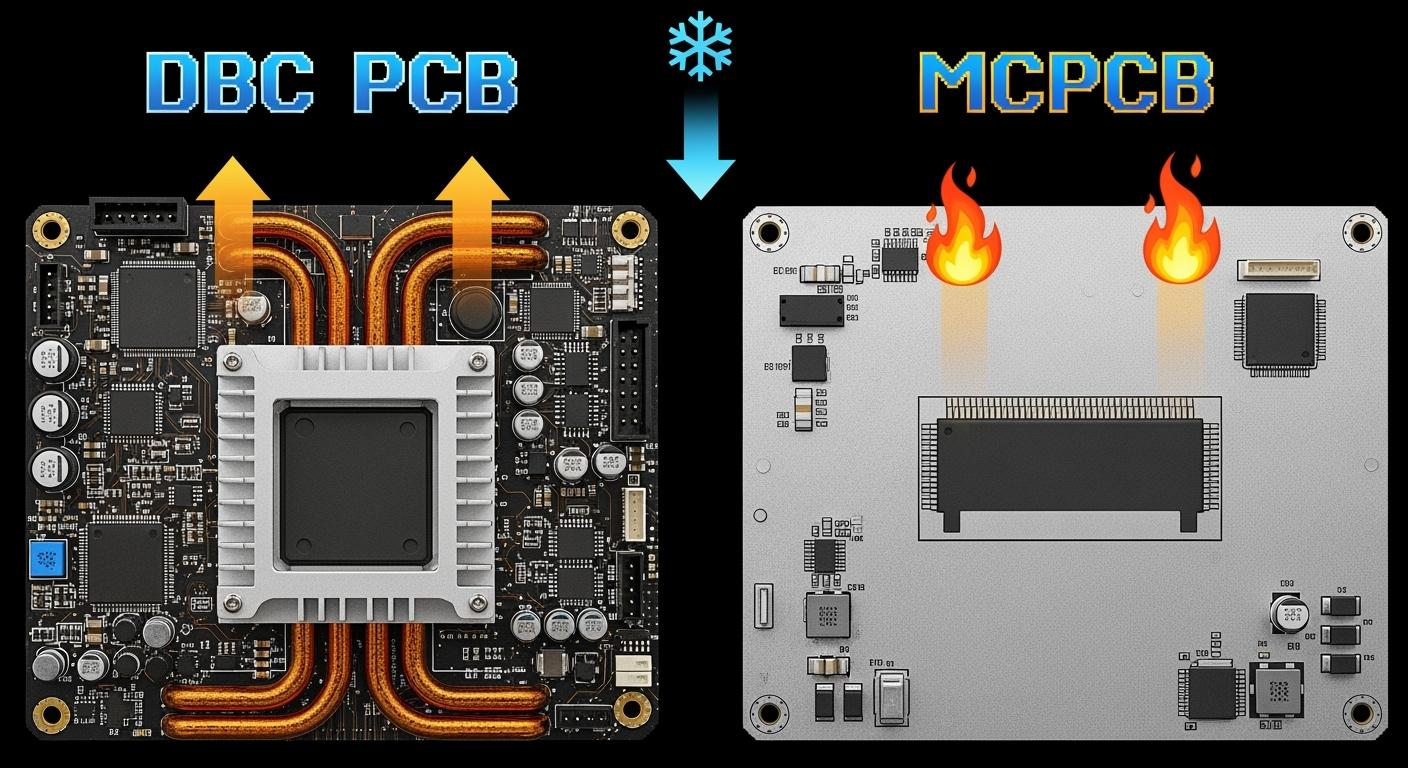

Comparison of DBC PCBs and MCPCBs for Cooling Performance

Good cooling is important in high-power electronics. DBC PCBs for cooler applications often cool better than MCPCBs. This is because DBC PCBs have high thermal conductivity. The direct bonding in DBC PCBs allows heat to move quickly to the substrate. While MCPCBs also help dissipate heat, their metal core is not as effective as a DBC PCB for cooler performance. Choosing the right PCB ensures that devices remain safe and operate efficiently.

Key Takeaways

- DBC PCBs cool better because they move heat fast. Their ceramic base helps with cooling. This makes them great for high-power uses.

- MCPCBs cost less and work well for low-power devices. They are good for things like regular LED lights. These devices do not need much cooling.

- Picking the best PCB depends on how much cooling you need. It also depends on your budget and how reliable the device must be.

- DBC PCBs last longer in tough places. MCPCBs are better for simple designs. They are good for projects with less money to spend.

DBC PCB and MCPCB Overview

DBC PCB Structure

A DBC PCB has a ceramic base. This base is usually aluminum oxide or aluminum nitride. Makers attach a thin copper layer to the ceramic. They use high heat to bond the copper. The copper sticks tightly to the ceramic. The ceramic helps heat move away fast. DBC PCB For Cooler devices use this design for good cooling.

MCPCB Structure

An MCPCB has a metal core. The core is often aluminum or copper. There is an insulating layer on top of the metal. Then, a copper circuit layer goes above the insulation. The metal core spreads heat from the parts. The insulation keeps the copper and metal apart. This stops electrical problems. MCPCBs work well when some heat needs to be removed.

Heat Management Methods

Both DBC PCBs and MCPCBs handle heat in special ways:

- DBC PCBs move heat from copper to ceramic. The ceramic spreads the heat well.

- MCPCBs use the metal core to take in heat. The insulation stops electrical shorts.

Note: DBC PCBs work better in high-power places. Their ceramic base moves heat faster than the metal core in MCPCBs. This makes DBC PCB For Cooler choices great for tough cooling jobs.

Here is a table that shows the differences:

| Feature | DBC PCB | MCPCB |

|---|---|---|

| Substrate Material | Ceramic | Metal (Aluminum/Copper) |

| Thermal Conductivity | Very High | Moderate |

| Bonding Method | Direct Copper Bonding | Lamination |

| Typical Applications | Power Modules, Inverters | LEDs, Power Supplies |

Cooling Performance

Thermal Conductivity

Thermal conductivity shows how well something moves heat. DBC PCBs have a ceramic base like aluminum nitride. This ceramic moves heat very well. Copper is bonded directly to the ceramic. This bond is strong and helps heat move fast. Heat goes from the copper to the ceramic quickly. MCPCBs have a metal core, usually aluminum. There is an insulating layer on top. The insulation slows down the heat. So, DBC PCB For Cooler designs move heat better than MCPCBs. Good thermal conductivity keeps electronics safe and cool.

| PCB Type | Base Material | Thermal Conductivity (W/mK) |

|---|---|---|

| DBC PCB | Ceramic (AlN, Al2O3) | 24-180 |

| MCPCB | Aluminum/Copper | 1-5 (with insulation) |

Note: DBC PCB For Cooler uses ceramic to move heat away fast. This is much quicker than metal core boards.

Heat Dissipation

Heat dissipation means how well a PCB spreads heat. DBC PCBs use ceramic to spread heat evenly. The copper and ceramic are bonded directly. This makes it easy for heat to flow. Less heat gets stuck in the board. MCPCBs use a metal core to take in heat. The insulation between copper and metal slows this down. DBC PCB For Cooler moves heat away better in high-power places.

- DBC PCBs: Spread heat fast across the ceramic base.

- MCPCBs: Use metal core, but insulation slows heat.

Temperature Management

Good temperature management keeps devices safe. DBC PCBs move heat away from important parts. The ceramic base does not change much when hot. This keeps the board steady. MCPCBs can handle some heat, but insulation may cause hot spots. DBC PCB For Cooler keeps temperatures lower and steady. This helps stop damage and makes devices last longer.

Engineers pick DBC PCBs for systems needing tight temperature control and long life.

DBC PCB For Cooler Applications

Many industries use DBC PCB For Cooler when strong cooling is needed. Power electronics, electric cars, and machines need boards that handle lots of heat. DBC PCBs cool best because they move and spread heat well. MCPCBs work for things like LED lights where less cooling is fine. When choosing, engineers look at how much heat the device makes and how important cooling is.

- DBC PCB For Cooler fits high-power modules and inverters.

- MCPCBs work for lower-power devices with less heat.

DBC PCB For Cooler is the best choice for tough cooling jobs.

Application Suitability

High-Power Electronics

High-power electronics need good cooling to stay safe. Devices like power inverters and motor drives use DBC PCB For Cooler. The ceramic base in DBC PCBs moves heat away fast. This keeps important parts cool. MCPCBs can handle some heat, but not as much as DBC PCBs.

Engineers pick DBC PCBs for high-power modules. They help devices work well and last longer.

LED and Lighting

LED lights make heat that can lower brightness and life. MCPCBs work well for most LED lights. Their metal core spreads heat from the LEDs. This helps keep lights cool and bright. MCPCBs cost less and fit many lighting designs. DBC PCBs are used for high-power LED arrays. Most regular lights use MCPCBs because they balance cooling and price.

- MCPCBs: Good for most LED lights and displays.

- DBC PCBs: Used for special, high-power LED systems.

Automotive and Industrial

Cars and factories need strong cooling. Electric vehicles and robots use DBC PCB For Cooler. The ceramic base resists heat and shaking. This makes DBC PCBs great for car power modules and factory drives. MCPCBs are used in easier jobs, like dashboard lights or small controls.

| Application Area | Preferred PCB Type | Reason |

|---|---|---|

| Power Electronics | DBC PCB | Best at moving heat |

| Standard LED Lighting | MCPCB | Cheap and cools well |

| Automotive Power Units | DBC PCB | Reliable and cools strongly |

For tough cooling jobs, DBC PCB For Cooler works best. MCPCBs are good for easier uses.

Readers can ask the team for help picking the right PCB.

Practical Considerations

Cost Factors

Cost is important when picking DBC PCBs or MCPCBs. DBC PCBs use ceramic and direct copper bonding. These steps make DBC PCBs cost more to make. MCPCBs use metal cores and simple lamination. This keeps MCPCBs cheaper. MCPCBs are good for projects with small budgets. DBC PCBs cool better and can stop devices from breaking. This can save money later.

| PCB Type | Material Cost | Manufacturing Cost | Total Cost Level |

|---|---|---|---|

| DBC PCB | High | High | $$$ |

| MCPCB | Moderate | Low | $ |

Tip: Teams should think about saving money now or later with better cooling.

Reliability

Reliability is very important for strong systems. DBC PCBs use ceramic bases that fight heat and stress. These boards last longer in tough places. MCPCBs work well for medium heat but may not last as long. DBC PCBs handle changes in heat better. This means fewer cracks and problems over time.

- DBC PCBs: Very reliable and strong.

- MCPCBs: Good for lighter jobs.

Design Flexibility

Design flexibility helps engineers meet project needs. DBC PCBs can have complex layouts and many parts. Their ceramic base lets parts be close and shapes be special. MCPCBs are less flexible because of their metal core and insulation. They work best for simple and flat designs.

Note: DBC PCBs are better for special shapes or lots of parts.

Picking the right PCB depends on cost, reliability, and design. Readers can ask the team for help with custom designs or cooling questions.

Picking DBC PCBs or MCPCBs depends on what you need. You should think about how much cooling is needed, how much money you have, and how long you want the board to last.

- DBC PCBs are good for strong electronics and places that get rough.

- MCPCBs are better if you want to save money or use them in normal lights.

If you want help, you can ask the team for advice or send your questions on the website.

HOME

HOME