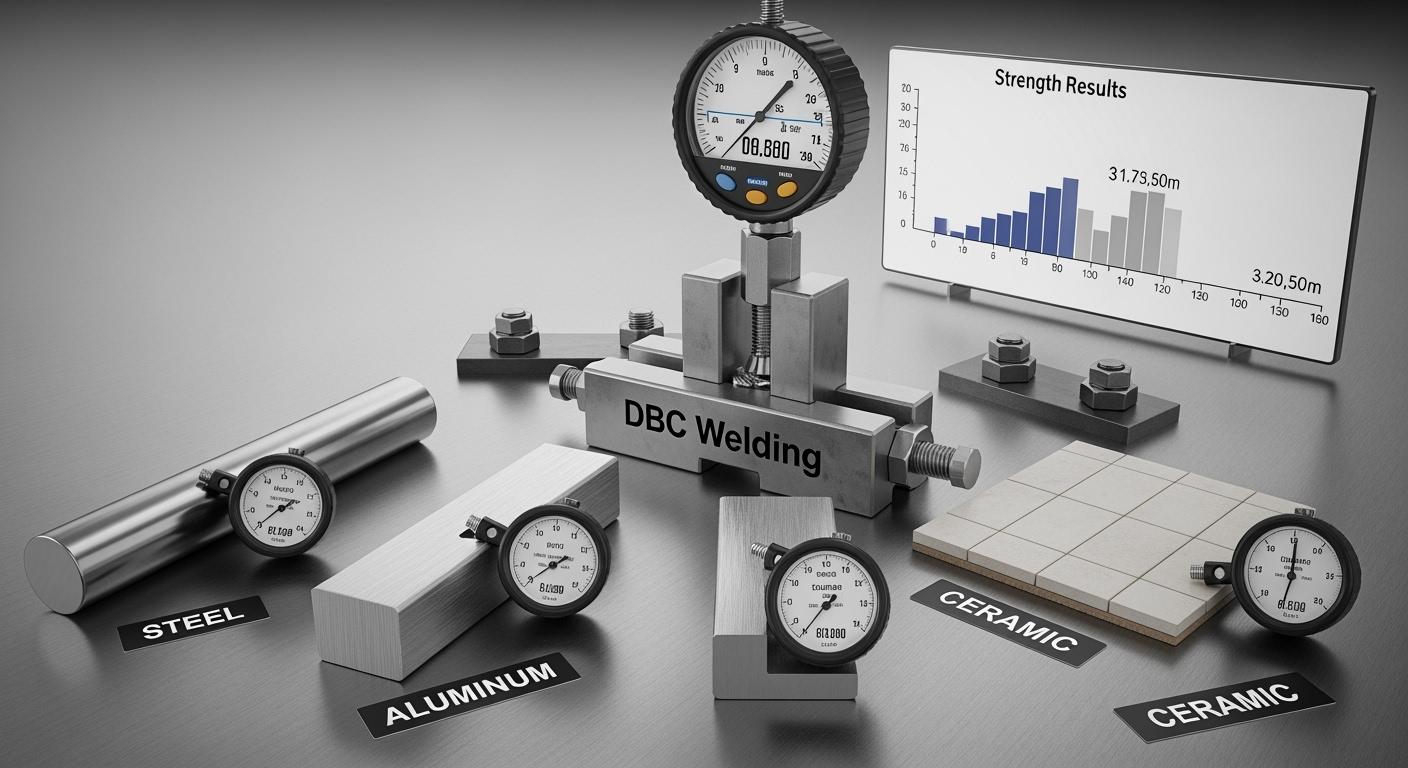

DBC Welding Strength Compared to Other Materials

When you look at DBC Welding Strength and other materials, you can see they work differently. Welding strength is important because it shows if a joint will stay strong or break when used. Sometimes, if you use the best filler metal and welding way, the weld can be even stronger than the first material. You should always think about these things before you choose a material for your project.

Key Takeaways

- DBC Welding Strength uses copper and ceramic together. This makes a strong joint that can handle heat. People use it in electronics and power modules.

- DBC is better than regular copper for heat and cracks. It works well when things get stressed.

- Aluminum is light but can break when stressed. Pick DBC for strong joints in places with lots of heat.

- Steel is very strong and holds heavy things. DBC works best for electrical jobs. Choose the right material for your project.

- Always pick the best filler metal and welding way. This helps make welds strong and safe. Check your work to make sure it is good.

DBC Welding Strength Overview

Definition and Key Properties

You might hear about DBC Welding Strength when working with special materials. DBC means Direct Bonded Copper. This material has a copper layer stuck to a ceramic base. It makes a joint that is strong and does not break easily. The joint can handle high heat and lots of electricity. DBC Welding Strength tells us how well the copper stays on when things get hot or stressed.

Here are some important properties you should know:

- High thermal conductivity

- Strong electrical performance

- Good resistance to cracking

- Stable under high temperatures

These properties help DBC Welding Strength work well in electronics, power modules, and car parts.

Why Welding Strength Matters

You need to trust your welds to keep things safe. If a weld breaks, your whole project might stop working. DBC Welding Strength helps you feel sure your joints will last, even when things get hard. You do not want weak spots that could crack or cause electrical problems.

Tip: Always check the welding strength before picking a material for tough jobs.

A strong weld lets you use less material but still get good results. That means you save money and make things lighter. Your products also last longer and are safer. When you look at DBC Welding Strength and other materials, you see why engineers like to use it for hard jobs.

Sometimes, people write DBC weld strength or DBC Welding Strength. Both mean the same thing, so do not worry.

DBC Welding Strength vs. Copper

Strength Comparison

You need to know how DBC Welding Strength compares to regular copper. Copper is a soft metal. It bends easily and carries electricity well. When you weld copper, the joint can become a weak spot. The heat from welding can change the copper’s structure. This makes the weld less strong than the rest of the copper sheet.

DBC Welding Strength gives you a stronger bond. The copper in DBC bonds to a ceramic base. This bond does not break as easily as a regular copper weld. You can trust DBC to hold up under high heat and stress. The ceramic base helps the copper stay in place. You get a joint that resists cracking and does not melt as fast.

Here is a quick look at how they compare:

| Property | DBC Welding Strength | Regular Copper Weld |

|---|---|---|

| Heat Resistance | High | Medium |

| Crack Resistance | Strong | Weak |

| Electrical Conductivity | High | High |

| Durability | Excellent | Good |

Note: If you need a joint that will not fail under stress, DBC Welding Strength is a better choice than plain copper.

Typical Applications

You see copper used in many places. People use it for wires, pipes, and electrical contacts. These jobs need good conductivity, but not always high strength. When you need a joint that will not break, you should look at DBC.

You find DBC Welding Strength in power modules, electric cars, and high-power LED lights. These products get hot and need strong joints. DBC works well because it keeps the copper stuck to the ceramic, even when things heat up. You can use DBC in places where regular copper would fail.

- Power electronics

- Automotive inverters

- Industrial machines

- High-frequency circuits

Tip: Choose DBC when you need both strength and electrical performance. For simple wiring, regular copper is enough.

If you want your project to last longer and work better, you should think about DBC Welding Strength. It gives you more options and better results than just using copper alone.

DBC Welding Strength vs. Aluminum

Durability and Use Cases

When you compare DBC Welding Strength to aluminum, you notice big differences in how each material performs. Aluminum feels light and easy to shape. Many people use it for parts that need to be lightweight, like airplane wings or bike frames. However, aluminum welds can weaken under stress or heat. The joints may crack or lose strength if you push them too hard.

DBC Welding Strength gives you a tougher bond. The copper layer in DBC sticks to ceramic, making the joint resist heat and stress much better than aluminum. You can rely on DBC for jobs that need strong, long-lasting connections. The ceramic base keeps the copper from moving or breaking, even when temperatures rise.

Here’s a quick table to help you see the difference:

| Property | DBC Welding Strength | Aluminum Weld |

|---|---|---|

| Heat Resistance | Excellent | Fair |

| Crack Resistance | High | Medium |

| Weight | Heavy | Light |

| Durability | Superior | Good |

Note: If you need a weld that lasts in tough conditions, DBC works better than aluminum.

You find aluminum in car bodies, window frames, and soda cans. These products need to be light and easy to make. DBC fits best in electronics, power modules, and places where heat and stress are high. You should pick DBC when you want your welds to stay strong for a long time.

- Use aluminum for lightweight jobs.

- Choose DBC for high-power electronics and heat-heavy environments.

Sometimes, people forget that aluminum welds can fail if you use them in the wrong place. DBC Welding Strength helps you avoid these problems. If you want reliability, DBC is the way to go. (Oops, forgot to mention: DBC is a bit heavier than aluminum, so keep that in mind for weight-sensitive projects.)

DBC Welding Strength vs. Steel

High-Stress Performance

You often see steel used in places where strength matters most. Steel stands up to heavy loads, impacts, and tough conditions. You might find it in bridges, car frames, or building supports. When you weld steel, you get a joint that can handle a lot of force. The welds usually match the strength of the steel itself, especially if you use the right filler rod and technique.

DBC Welding Strength gives you a different kind of performance. The copper layer bonds to a ceramic base, which helps the joint resist heat and cracking. You get a strong connection, but it works best in electrical and thermal settings. DBC does not match steel for raw strength in heavy construction, but it shines in high-stress electronic environments.

Here’s a quick table to help you compare:

| Property | DBC Welding Strength | Steel Weld |

|---|---|---|

| Tensile Strength | Moderate | Very High |

| Heat Resistance | Excellent | Good |

| Crack Resistance | High | High |

| Electrical Conductivity | High | Low |

| Weight | Heavy | Heavy |

Note: If you need a weld for carrying electricity and handling heat, DBC works better. For holding up a building or a car, steel is the clear winner.

You should pick steel when you need to support weight or resist bending. Use DBC when your project needs to move electricity and stay cool under stress. Both materials have their place, but you must match the material to the job.

- Use steel for bridges, frames, and tools.

- Choose DBC for power modules, circuit boards, and high-heat electronics.

If you try to use DBC where steel belongs, you might see the joint fail. Always check the demands of your project before you decide.

DBC Welding Strength vs. Ceramics

Bonding and Practical Use

When you look at DBC welding strength and regular ceramics, you notice they act differently under stress and heat. Ceramics are good at stopping electricity and can handle high temperatures. But ceramics might crack or break if you push them too much. People use ceramics when they need to block electricity, like in insulators or circuit boards.

DBC means Direct Bonded Copper. It mixes copper and ceramic together in one piece. This gives you both strength and insulation. The copper sticks tightly to the ceramic base. This makes the joint strong and less likely to crack. DBC can handle heat better than just ceramics alone. You can trust DBC to stay strong when things get hot or stressed.

Here’s a simple table to show the differences:

| Property | DBC Welding Strength | Ceramic Only |

|---|---|---|

| Crack Resistance | High | Low |

| Heat Resistance | Excellent | Excellent |

| Electrical Conduct. | High | Very Low |

| Bonding Strength | Superior | Weak |

Tip: If you want insulation and strong joints, DBC works better than only ceramics.

Ceramics are used in spark plugs, tiles, and some electronics. These work fine until you need a joint that can take force or shaking. DBC is better when you want insulation from ceramic and strength from copper.

- Use ceramics for jobs that only need insulation.

- Pick DBC for power modules, LED boards, and places with lots of heat and stress.

Sometimes, you may think ceramics are enough, but they can break under heavy loads. DBC welding strength helps stop cracks and keeps your project working longer. If you want your project to last and work well, DBC is a good choice. (Oops, remember: DBC costs more than plain ceramics, so check your budget before you choose.)

Factors Affecting Welding Strength

Filler Metals and Welding Processes

You need to pay close attention to the filler metals you choose. The right filler metal can make your weld even stronger than the base material. For example, if you use a 7018 rod, you get a weld that resists cracking and holds up under stress. A 6010 rod gives you deep penetration, which helps when you need a strong root pass. Each filler metal has its own strengths and weaknesses. You should always match the filler metal to the job and the materials you work with.

The welding process also plays a big role in how strong your weld turns out. Stick welding, MIG, and TIG all create different weld profiles. TIG welding gives you clean, precise welds, which work well for thin materials. MIG welding lets you work faster and cover more area, but you might not get as much penetration. Stick welding works well outdoors and on dirty surfaces, but it can leave slag that you need to clean up.

Penetration matters a lot. If your weld does not go deep enough into the base material, the joint can break under load. You want a weld that fuses both pieces together all the way through. Sometimes, you might see a weld that looks good on the outside but has weak spots inside. Always check your welds for proper penetration and fusion.

Tip: Use the right filler metal and welding process for your material. Test your welds to make sure they hold up under real-world stress.

Environmental and Material Factors

The environment where you weld can change the strength of your joint. High temperatures can weaken some materials and cause the weld to lose strength. If you weld in a cold area, the metal might crack more easily. Humidity and moisture can lead to rust or contamination, which makes the weld weaker.

Material composition also affects welding strength. Some metals, like stainless steel, resist corrosion and hold up well over time. Others, like plain carbon steel, might rust or lose strength if you do not protect them. The way you bond the materials matters too. If you use a poor bonding method, the weld can fail even if the materials are strong.

DBC Welding Strength depends on both the copper and ceramic layers. The ceramic base gives you insulation and heat resistance. The copper layer provides electrical conductivity and strength. If you do not bond these layers well, the joint can crack or separate when stressed. Always check the specs for your materials and follow best practices for bonding.

Here is a quick checklist to help you get the best welding strength:

- Choose the right filler metal for your base material.

- Pick a welding process that matches your job.

- Control the temperature and keep your work area clean.

- Check the material composition and bonding method.

- Inspect your welds for cracks, weak spots, or poor penetration.

Note: Even a small mistake in your process can lead to a weak weld. Take your time and double-check your work.

If you want your project to last, you need to think about all these factors. Welding is not just about melting metal together. You must control every step to get the best results.

Choosing the Right Material

When to Use DBC

You need to choose the best material for your project. DBC Welding Strength is great when you need a joint that can take high heat and strong electricity. If you build power modules, electric car parts, or LED boards, DBC is a smart choice. The copper layer sticks to ceramic and makes a tough joint. This joint does not crack easily and keeps working when things get hot.

You should use DBC if:

- Your project gets very hot.

- You need good electrical flow.

- You want joints that last long.

- You work with electronics or power tools.

Tip: If your welds break in hard jobs, DBC could help.

Sometimes, DBC costs more than other materials. You have to think about both price and how well it works. If your project needs to be strong and last, DBC is worth the money.

Alternatives for Different Needs

You have other materials to pick if DBC is not right. Each one has its own good points. Here is a table to help you see the differences:

| Material | Best For | Weaknesses |

|---|---|---|

| Copper | Simple wiring, low cost | Soft, weak welds |

| Aluminum | Lightweight builds | Cracks under stress |

| Steel | Heavy loads, frames | Poor conductivity |

| Ceramics | Insulation, heat proof | Brittle, weak joints |

Pick copper for easy electrical work. Aluminum is good for light things like bike frames. Steel is best for heavy jobs, like bridges or car frames. Ceramics are good for insulation but can break if pushed too hard.

Note: Always pick the material that fits your project. If you need both strength and good electricity, DBC is the best.

If you want to spend less, use copper or aluminum. For the most strength, pick steel. If you need insulation, use ceramics. DBC Welding Strength gives you both toughness and good electricity, so it is great for hard electronic jobs.

You saw how DBC Welding Strength stands out against copper, aluminum, steel, and ceramics. Use DBC when you need strong, heat-resistant, and reliable joints in electronics or power modules. Always check your filler metals and welding process for the best results.

- Pick DBC for high-stress, high-heat jobs.

- Use other materials for lighter or less demanding tasks.

Remember: The right weld and enviroment make all the difference.

FAQ

What makes DBC welding strength unique?

You get a strong bond between copper and ceramic. This combo resists heat and cracking. DBC joints work well in electronics and power modules. You can trust these joints to last longer than regular metal welds.

Can DBC replace steel in heavy-duty projects?

No, you should not use DBC for heavy loads or building supports. Steel gives you higher tensile strength. DBC works best in electronics where you need heat resistance and electrical flow.

Is DBC welding strength affected by temperature changes?

Yes, but DBC handles high temps better than most metals. The ceramic base keeps the copper stable. You see less cracking or melting, even when things heat up fast.

How do I choose the right filler metal for DBC?

You need to match the filler to both copper and ceramic. Always check the specs. If you use the wrong filler, the weld might fail. Pro tip: Ask a welding expert if you feel unsure.

HOME

HOME