The Ultimate Guide to Alumina Circuit Board (Al2O3): High-Performance Ceramic PCB Solutions for Global Electronics

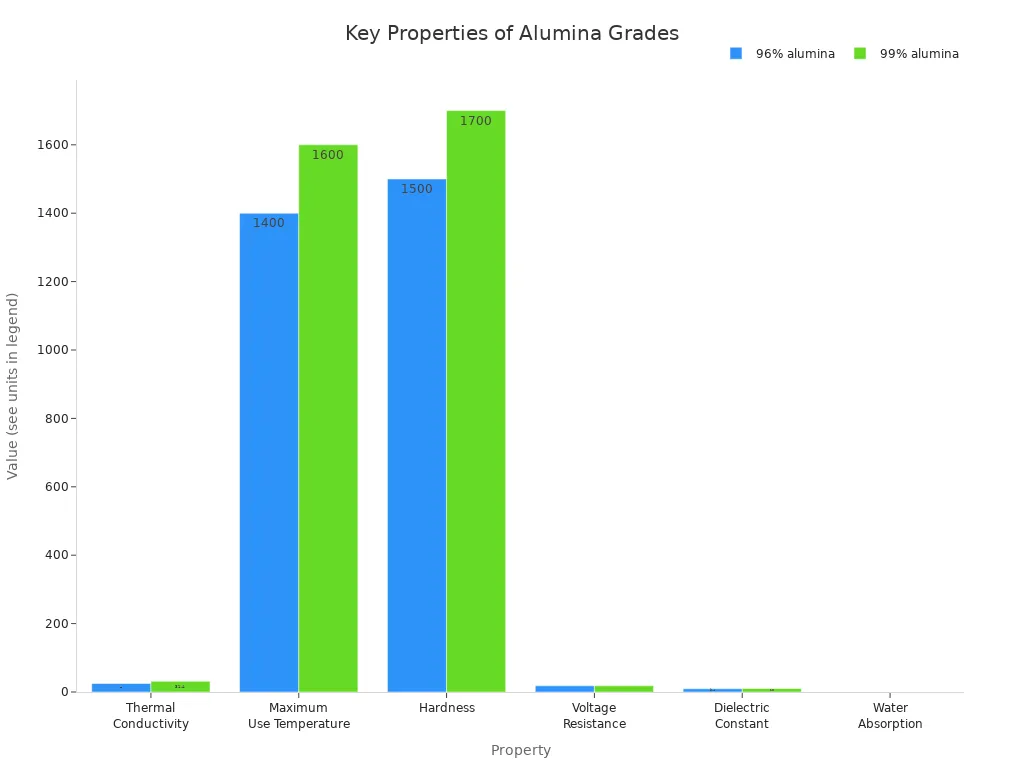

You want your electronics to work well under stress. Alumina Circuit Board technology helps you a lot. Pick alumina ($Al_2O_3$) because it moves heat fast, is very hard, and does not rust. These features help your devices deal with high heat, strong force, and tough places. Purity levels change how well it works:

| Property | 96% alumina | 99% alumina |

|---|---|---|

| Thermal Conductivity | 25W/(m·K) | 31.4W/(m·K) |

| Maximum Use Temperature | 1400°C | 1600°C |

| Hardness | 1500HV | 1700HV |

| Voltage Resistance | 18KV | 18KV |

| Dielectric Constant | 9.4 | 10 |

| Water Absorption | 0% | 0% |

Trust alumina PCBs to make your systems last longer and work better.

Key Takeaways

- Alumina circuit boards work well in places with a lot of heat and stress. This makes them great for power electronics.

- If you pick high-purity alumina (99%), it helps heat move better. It also makes the board stronger, so devices last longer.

- Alumina is better than regular FR4 boards because it handles heat better. It is also tougher and lasts longer.

- Special ways to make these boards, like DPC and DBC, help metal parts stick well. This makes the circuits work better and break less often.

- BST gives fast price quotes and ships all over the world. This makes it simple to get good alumina PCBs for your projects.

Why Alumina Circuit Board (Al2O3) is Dominating Modern Power Electronics

Understanding the Material Excellence of $96%$ to $99.6%$ Alumina

You want your electronics to work well and last long. Alumina Circuit Board technology helps you do this. When you pick alumina with 96% to 99.6% purity, you get many good things. High-purity alumina handles heat well. It does not crack easily. It keeps your circuits safe from water and chemicals.

You can count on alumina in hard places. It stays strong when it gets hot. It does not soak up water. This means your devices keep working, even if it is hot or wet. Many engineers use alumina for power electronics. It does not break when under stress.

Tip: If you want your circuit boards to last in tough places, pick high-purity alumina. It helps your products manage heat better and last longer.

Alumina vs. Traditional FR4: Breaking the Thermal Barrier

Most people know FR4 is used for many circuit boards. FR4 is fine for simple jobs. But it cannot handle a lot of heat. If you use FR4 in power electronics, it might get too hot and stop working. Alumina Circuit Board technology is different. It moves heat away from parts much faster than FR4.

Here is how alumina and FR4 are different:

| Feature | Alumina Circuit Board | FR4 Circuit Board |

|---|---|---|

| Thermal Conductivity | 25-31.4 W/(m·K) | 0.3 W/(m·K) |

| Max Use Temperature | Up to 1600°C | Up to 130°C |

| Mechanical Strength | Very High | Moderate |

| Water Absorption | 0% | Up to 0.2% |

You can see the difference. Alumina keeps electronics cool and safe. It works well in high-power systems. FR4 cannot do this.

More companies now use alumina in power electronics. Here are some trends:

- The aluminum organic polymer capacitance market is growing fast. It may reach $4.12 billion by 2032.

- North America has the biggest share at 35%.

- Asia-Pacific is growing fast because more electronics are made there.

- These new materials are important in power supply circuits and voltage regulation modules.

You want your products to be the best. Alumina Circuit Board solutions help you beat the heat and work better. Try them and see the change in your next project.

Precision Manufacturing of Alumina Circuit Boards: The BST Ceramic Perspective

You want your electronics to work their best. You need a circuit board that can handle heat and stress. It should also work in tough places. Alumina gives you three big benefits:

- High thermal conductivity keeps devices cool.

- Low thermal expansion stops cracks and warping.

- Strong mechanical durability protects circuits from damage.

If you pick 99% purity alumina, you get even better results. This material works well in very hot and harsh places. Your products stay reliable, even when things get tough.

Thick Film vs. Thin Film Technology on Al2O3 Substrates

You have two main ways to build circuits on alumina. These are thick film and thin film technology. Each way has its own good points.

| Feature | Thick Film Technology | Thin Film Technology |

|---|---|---|

| Layer Thickness | 10-50 μm | 0.1-1 μm |

| Circuit Density | Medium | High |

| Cost | Lower | Higher |

| Application | Power modules, sensors | RF, high-frequency |

Thick film technology uses screen printing to add conductive paste. You get strong layers for power electronics. Thin film technology uses vacuum deposition. You get very precise and dense circuits for advanced uses.

Tip: Pick thin film for high-frequency needs. Pick thick film for strong power modules.

Advanced Metallization Processes: DPC and DBC Techniques

You want your Alumina Circuit Board to last a long time. You need metal layers that stick well to the ceramic. Two advanced methods help you do this:

- Direct Plated Copper (DPC): Chemical vapor deposition makes a thin copper layer. This process gives great adhesion and smooth surfaces.

- Direct Bonded Copper (DBC): Thick copper sheets bond to alumina at high heat. This method makes a strong connection for high currents and heat.

| Process | Copper Thickness | Thermal Performance | Typical Use |

|---|---|---|---|

| DPC | 10-300 μm | Excellent | LED, sensors |

| DBC | 100-500 μm | Superior | Power modules |

These metallization techniques give you reliable performance and long life. Your circuits resist rust and stress.

Quality Control Protocols: Ensuring Zero-Defect Ceramic PCBs

You want every board to work perfectly. BST Ceramic uses strict quality checks to make sure there are no defects.

- Automated optical inspection checks every part.

- Electrical testing finds hidden problems.

- Thermal cycling tests show durability in tough conditions.

Note: You can trust BST Ceramic for flawless Alumina Circuit Board solutions. Every board meets top standards for safety and reliability.

You get peace of mind. Your electronics work well. Your customers stay happy.

Driving Innovation: Global Applications of Alumina (Al2O3) PCB Technology

Aerospace and Defense: Meeting Rigorous Standards in the USA and UK

You want your electronics to last in tough places. In aerospace and defense, only strong materials work. Alumina Circuit Board solutions give you strength and heat resistance. They are also very reliable. Many big companies use alumina for important systems.

- Engecer makes electron-beam position monitors with alumina. These are used in synchrotron light sources.

- Top aerospace companies in the USA and UK use alumina PCBs. They use them for radar, avionics, and satellites.

If you pick alumina, you meet strict military rules. You protect your gear from heat, shaking, and wetness.

Automotive and EV Power Modules: The Growing Demand in Italy and Turkey

You see electric cars everywhere now. Car makers in Italy and Turkey want safer power modules. They also want them to last longer. Alumina PCBs help control high currents and heat in EVs. They make charging stations and battery packs more reliable.

| Benefit | Impact on EVs |

|---|---|

| High thermal stability | Stops overheating |

| Strong insulation | Prevents short circuits |

| Zero water absorption | Makes parts last longer |

You can trust alumina to keep car electronics safe. It works well in bad weather and busy traffic.

Telecommunications and 5G Infrastructure in Brazil and Colombia

You need fast and steady connections. Telecom companies in Brazil and Colombia use alumina PCBs. They use them for 5G base stations and network hardware. These boards handle high frequencies and power without breaking.

- Alumina supports signals at high frequencies.

- It resists heat from working all the time.

- It keeps networks running in hot or wet places.

Pick alumina for your telecom projects. You get better signals and fewer problems.

High-Power LED Lighting and Industrial Sensors

You want bright lights that work well. You want sensors that last a long time. Alumina PCBs help with both. They move heat away from LEDs and sensors. Your products shine brighter and last longer.

- Use alumina for streetlights, factory lights, and smart sensors.

- You spend less on repairs and get better results.

Try alumina and see how your next project improves.

The Future of Ceramic Substrates: Partnering with BST for Your Next Project

How to Get a Rapid Quote for Your Alumina Circuit Board Design

You want to move fast in today’s electronics market. BST makes it easy for you to get a quote for your custom Alumina Circuit Board. You do not wait days for answers. You get a personal Customer Concierge who listens to your needs right away. You talk to technical experts who help you define your project. You receive your quote quickly, often on the same day.

Here is how the process works:

| Step | Description | Turnaround Time |

|---|---|---|

| Initial Contact | You connect with a Customer Concierge who gathers your order info. | Immediate engagement |

| Technical Definition | You work with experts to set your technical requirements. | Same day or up to 1 day |

| Quote Delivery | You receive your quote based on your needs. | Usually same day |

Tip: You save time and avoid delays. You get clear answers and fast support for your design.

Global Shipping and Technical Support for New Zealand to South America

You want your project to reach the world. BST ships ceramic PCBs to many countries, from New Zealand to South America. You get reliable delivery and tracking for every order. You do not worry about customs or paperwork. BST handles it for you.

You also get technical support at every step. You can ask questions about design, production, or shipping. BST’s team helps you solve problems fast. You get updates and advice, no matter where you are.

- Fast shipping to over 50 countries

HOME

HOME