Ceramic Substrate or Aluminum PCB for High-Power LEDs

You want your high-power LEDs to work well. High-power LED ceramic substrate PCB gives you great heat transfer and is very reliable. This choice is good for tough places but costs more money. Aluminum PCBs are cheaper and still spread heat well. You should think about your budget, how long you need the LEDs to last, and where you will use them.

Key Takeaways

- Pick aluminum PCBs if you want to save money. They help control heat well and cost less.

- Use ceramic substrates if you need strong heat resistance. They work well in tough places and last a long time.

- Think about what your project needs. Look at heat, environment, and cost before you choose a PCB.

- Ceramic PCBs cost more at first, but they last longer. They need less fixing, so they are worth it over time.

- Check the comparison tables to help you decide. The tables show differences in heat control, insulation, and how long they last.

High-Power LED Ceramic Substrate PCB vs. Aluminum Substrate

Key Differences

It is important to know how a high-power led ceramic substrate pcb and an aluminum PCB are not the same. They are made from different materials. Each one has its own good points. The table below helps you see the differences:

| Property | Aluminum Substrates | Ceramic Substrates |

|---|---|---|

| Thermal Conductivity | 200 to 250 W/m·K | 20 to 200 W/m·K (up to 170 W/m·K for aluminum nitride) |

| Cost | Generally more cost-effective | Higher cost, but justifiable for demanding applications |

| Mechanical Durability | Good mechanical durability | Exceptional heat resistance and insulation properties |

| Suitability | Ideal for LED lighting and power electronics | Suitable for high-frequency applications and thermal stress environments |

Aluminum PCBs move heat away fast and are strong. They are a good pick for most LED lights. A high-power led ceramic substrate pcb keeps heat steady and gives great insulation. These boards are best for places with lots of heat or strong electricity. Ceramic boards can handle heat better than aluminum ones.

Application Scenarios

Pick the board that fits your project best. Each board works well for different jobs:

- Aluminum PCBs are good for LED lights, street lamps, and power electronics. They spread heat well and do not cost much.

- A high-power led ceramic substrate pcb is better for car headlights, underwater lights, and high-frequency circuits. These boards are best for tough jobs.

- If you need strong insulation and heat safety, use a high-power led ceramic substrate pcb.

- For outdoor lights or places that shake a lot, aluminum PCBs are strong and last long.

- If your project needs to last a long time and work steady, a high-power led ceramic substrate pcb is a good choice.

Tip: Always pick the board that matches your project. This helps your LEDs work their best and saves money.

Thermal Conductivity and Heat Dissipation

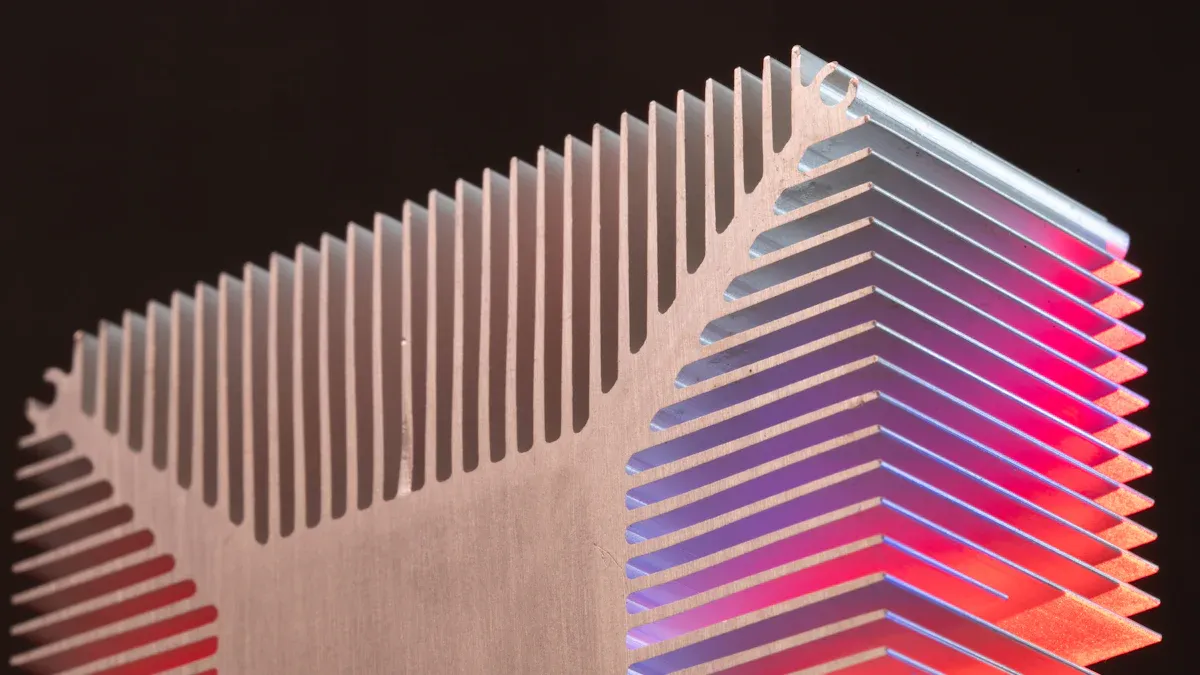

Ceramic Substrate PCB Thermal Performance

When you pick a PCB for high-power LEDs, you should think about how well it moves heat. Ceramic substrate PCBs are very good at getting rid of heat. Some materials, like aluminum nitride (AlN), can move heat really well, between 150 and 180 W/m·K. This means the board takes heat away from the LED chip very fast. Your LEDs can stay cool even when they are on for a long time. Ceramic substrates also keep the whole board at an even temperature. This stops hot spots and keeps your LEDs safe from getting too hot. You can count on ceramic PCBs to get rid of heat in hard jobs. These boards are used in car headlights, underwater lights, and other places where you need good heat control.

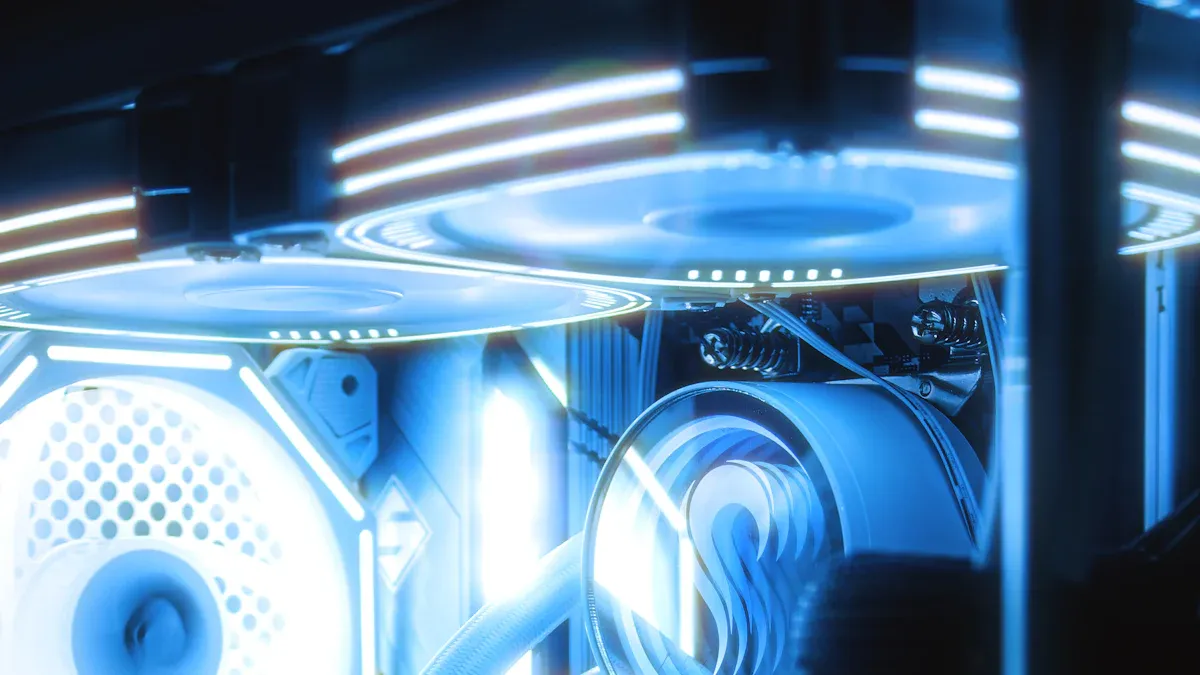

Aluminum Substrate Heat Management

Aluminum PCBs also help with heat, but they do not move heat as well as ceramic. Most aluminum foil PCBs for high-power LEDs have a thermal conductivity of about 2 W/(m*K). Here is a simple table:

| Material Type | Thickness | Thermal Conductivity |

|---|---|---|

| Aluminum foil PCB | 1.5mm | 2 W/(m*K) |

This means aluminum PCBs can still get rid of heat for many LED uses. You get good heat control for street lights, indoor panels, and regular lights. Aluminum substrates spread heat well enough for most jobs, especially if you want to save money and still control heat. You should use aluminum PCBs if your project does not need super high heat movement but still needs to get rid of heat.

Note: Always pick a PCB that matches how much power your LED uses. This helps your LEDs last longer and stay safe.

Performance Comparison and Reliability

Lifespan and Stability

You want your high-power LEDs to last a long time. Ceramic substrate PCBs help your LEDs stay cool. This keeps them working well for years. Ceramic boards do not bend or change shape when hot. The board stays strong and does not shrink or grow. You get steady performance because the board does not break easily. Aluminum PCBs are also tough and handle heat and bumps. But they do not keep heat away as well as ceramic. If you want the best choice for long life, ceramic substrates are better. They wear out less and break down less often. This makes ceramic a smart pick for important projects.

Suitability for Harsh Environments

Sometimes your LEDs need to work in hard places. Ceramic substrate PCBs do well in high heat, wet spots, and places that shake. Their thermal stability keeps your LEDs safe from quick heat changes. Ceramic boards are strong and do not rust or let water in. They also block chemicals. Aluminum PCBs work well outside or in factories. They are strong and do not rust fast. But they do not handle very high heat as well as ceramic. For tough jobs, ceramic substrates work better. Pick ceramic if you need your LEDs to work in cars, underwater, or outside.

Tip: Always choose the PCB that fits your environment. This helps your LEDs last longer and stay cool.

| Feature | Aluminum PCB | Ceramic Substrate PCB |

|---|---|---|

| Thermal Stability | Good | Excellent |

| Durability | High | Very High |

| Corrosion Resistance | Moderate | Excellent |

| Reliable Performance | Yes | Yes |

Ceramic substrates give you the best performance. They are great when you need your LEDs to stay strong and cool in hard jobs.

Cost and Value Analysis

Initial Cost

When you look at the cost comparison between ceramic and aluminum PCBs, you see a clear difference. Aluminum PCBs usually cost less. You can buy them for most high-power LED projects without spending too much. Manufacturers make aluminum boards in large numbers, so you get a lower price. If you need to keep your budget tight, aluminum PCBs give you a good balance between price and performance.

Ceramic PCBs cost more at the start. You pay a higher price because the materials and production process are more advanced. For high-power LED systems that need top-level heat control, you may find the extra cost worth it. If your project does not need extreme heat resistance, you can save money with aluminum.

Note: Always check your project needs before you decide. The right choice depends on your budget and how much heat your high-power LEDs produce.

Long-Term Value

You should not look at only the initial price. Think about how long your high-power LED system will last. Ceramic PCBs often give you better long-term value. They handle heat better and last longer in tough places. You may pay more at first, but you save money over time because you replace parts less often.

Here is a simple table for cost comparison:

| Substrate Type | Initial Cost | Lifespan | Maintenance Needs |

|---|---|---|---|

| Aluminum PCB | Low | Medium | Moderate |

| Ceramic PCB | High | Long | Low |

If you use your high-power LEDs in places with lots of heat or stress, ceramic PCBs can lower your total costs over time. You avoid frequent repairs and downtime. For regular lighting, aluminum PCBs work well and keep costs down.

Tip: Choose ceramic PCBs for high-power LED projects that need long life and top performance. Pick aluminum PCBs for standard jobs where you want to save money up front.

Practical PCB Selection Guide

Decision Factors

You need to pick the right pcb for your project. First, think about what your project needs. Ask yourself how much heat your LEDs will make. Look at your environment for water, shaking, or chemicals. Decide how long you want your printed circuit boards to last. Make sure you know your budget before you choose a pcb.

Here are some easy steps to help you:

- Write down how much power and heat your project uses.

- Think if you need strong electrical insulation for safety.

- See if your project will face water or shaking.

- Check if the cost of each pcb fits your budget.

- Decide how often you want to change your pcb.

White or copper substrates help move heat away and last longer. Thin foil substrates can get too hot and not last as long. For high-power jobs, you need a pcb that can handle heat and give good insulation. If you want the best performance, ceramic substrates are great for heat and insulation. Aluminum substrates work for most projects and cost less money.

Tip: Always pick a pcb that fits your project’s needs. This helps your LEDs last longer and work better.

Summary Table: Ceramic vs. Aluminum

Here is a simple table to help you compare:

| Feature | Aluminum PCB | Ceramic Substrate PCB |

|---|---|---|

| Thermal Management | Good | Excellent |

| Electrical Insulation | Moderate | Superior |

| Service Life | Medium | Long |

| Cost | Low | High |

| Best Use | General lighting, outdoor | High-power applications, harsh environments |

You can use this table to help you pick the right pcb. Look at heat control, insulation, and how long it lasts to get the best results.

You have learned how ceramic and aluminum substrates are different for led lighting. Aluminum PCBs work well for most high-power led lights. They spread heat and cost less money. Ceramic substrates are better if you need strong heat resistance or must use them in tough places. Pick aluminum for regular led lighting jobs. Use ceramic for jobs with high frequency or high temperature. Always choose the right one for your project. If your project is hard, ask an expert for help.

- Pick aluminum substrates when you need good heat control.

- Use ceramic substrates for power electronics or strong heat resistance.

- Think about your project, where you use it, and your budget before you choose.

FAQ

What makes aluminum substrate a popular choice for LED applications?

Many people pick aluminum substrate for LED projects. It saves money and works well for most lights. Aluminum substrate moves heat away from LEDs quickly. You can trust it to work and it is easy to make.

When should you select ceramic substrate over aluminum substrate for high-power LEDs?

Choose ceramic substrate if your LED project gets very hot or is in a tough place. Ceramic substrate gives better insulation and stays stable. It lasts longer and works better when you need top performance.

How does conductivity affect LED performance on different substrates?

Conductivity shows how fast heat leaves your LED. Aluminum substrate moves heat well for most jobs. Ceramic substrate moves heat even faster in hard jobs. Picking the right substrate keeps your LED from getting too hot.

What are the main differences in material properties comparison between ceramic and aluminum substrate?

Ceramic substrate has stronger insulation and better conductivity for tough jobs. Aluminum substrate is strong and costs less money. Comparing materials helps you pick what your LED needs.

Can you use aluminum substrate for underwater or automotive LED lighting?

Aluminum substrate works for many LED lights. Ceramic substrate is better for underwater or car lights. Ceramic substrate does not rust and handles big temperature changes. Your LEDs last longer in hard places with ceramic.

HOME

HOME