High Thermal Conductivity Ceramic PCB for Photovoltaic Applications

Table of Contents

- What Is a High Thermal Conductivity Ceramic PCB?

- Why Thermal Management Matters in Photovoltaic Systems

- Ceramic PCB Materials for High Heat Dissipation

- Flexible PCB and Rigid-Flex PCB Integration in Solar Applications

- Manufacturing Process and Quality Control Standards

- Typical Applications in Colombia’s Solar Energy Market

- How to Choose the Right Ceramic PCB Supplier

What Is a High Thermal Conductivity Ceramic PCB?

A high thermal conductivity ceramic PCB is a circuit board that uses a ceramic substrate instead of traditional FR4. Ceramic materials offer significantly higher heat dissipation, electrical insulation, and mechanical stability under extreme operating conditions.

Compared with metal-core PCBs or standard fiberglass boards, ceramic PCBs are designed to:

- Transfer heat efficiently from power components

- Maintain stable electrical performance

- Operate reliably in high-voltage and outdoor environments

Typical thermal conductivity values range from 24 W/m·K to over 170 W/m·K, depending on the ceramic material used.

Why High Thermal Conductivity Ceramic PCBs Are Critical for Photovoltaic Systems

Photovoltaic systems operate under continuous thermal stress. Solar inverters, IGBT modules, MOSFETs, and rectifiers generate substantial heat during power conversion.

Thermal Challenges in Solar Applications

- Continuous high current operation

- Outdoor temperature fluctuations

- UV exposure and humidity

- Long-term reliability requirements (10–25 years)

Without effective heat dissipation, traditional PCB materials can lead to:

- Component failure

- Delamination

- Reduced conversion efficiency

- Shortened system lifespan

High thermal conductivity ceramic PCBs address these issues by creating a direct thermal path from heat-generating components to heat sinks or cooling systems.

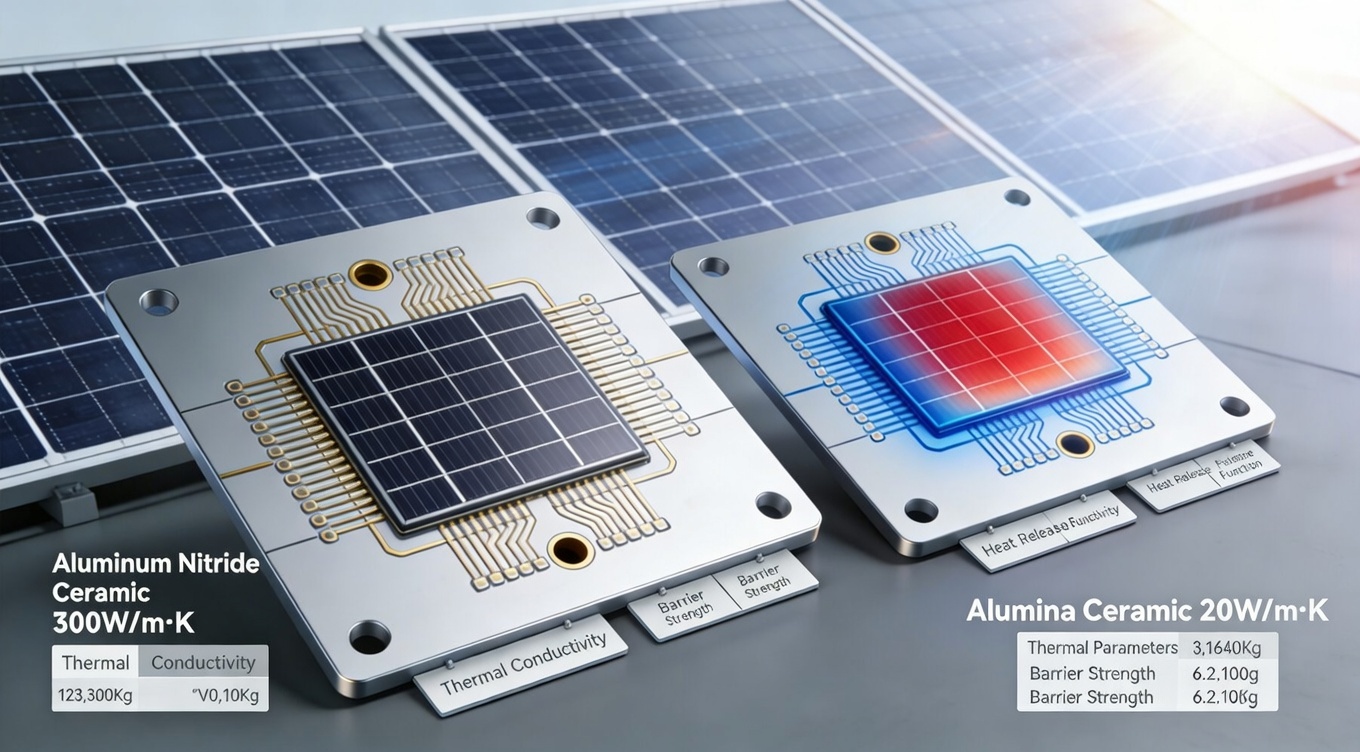

Material Selection: Ceramic PCB Substrates for Solar Power Applications

Choosing the right ceramic material is essential for photovoltaic systems.

Aluminum Oxide (Al₂O₃) Ceramic PCB

- Thermal conductivity: ~24 W/m·K

- Cost-effective

- Suitable for medium-power PV applications

Aluminum Nitride (AlN) Ceramic PCB

- Thermal conductivity: 150–170 W/m·K

- Ideal for high-power solar inverters

- Excellent thermal expansion match with copper

Silicon Nitride (Si₃N₄) Ceramic PCB

- High mechanical strength

- Superior thermal shock resistance

- Used in demanding outdoor solar installations

Flexible PCB and Rigid-Flex PCB Solutions in High-Power Photovoltaic Designs

Modern photovoltaic systems increasingly require compact, lightweight, and complex interconnections. This is where flexible PCB and rigid-flex PCB solutions complement ceramic substrates.

Flexible PCB in Solar Applications

Flexible PCBs are commonly used for:

- Sensor connections

- Control signal transmission

- Compact module interconnections

Their ability to bend and fold allows designers to optimize internal layouts without sacrificing reliability.

Rigid-Flex PCB Integration

Rigid-flex PCBs combine ceramic rigid sections with flexible interconnects, offering:

- Reduced connectors and solder joints

- Improved vibration resistance

- Higher assembly reliability

In photovoltaic inverters and power control units, rigid-flex ceramic PCB assemblies help maintain electrical stability while simplifying system architecture.

Manufacturing Process and Quality Control Standards

High thermal conductivity ceramic PCB manufacturing requires precise control at every stage.

Key Manufacturing Steps

- Ceramic substrate preparation

- Thick-film or DBC (Direct Bonded Copper) processing

- Precision etching and drilling

- Surface finishing (ENIG, silver, gold plating)

Quality and Reliability Testing

- Thermal cycling tests

- Dielectric withstand voltage testing

- Peel strength and solderability evaluation

- X-ray and AOI inspection

Compliance with ISO, IPC, and RoHS standards is essential for photovoltaic applications targeting international markets, including Colombia.

Typical Applications in Colombia’s Solar Energy Market

Colombia’s renewable energy sector has experienced steady growth in recent years, particularly in:

- Utility-scale solar farms

- Commercial rooftop systems

- Off-grid solar solutions

High thermal conductivity ceramic PCBs are widely used in:

- Solar inverters

- Power conversion modules

- Battery energy storage systems (BESS)

- DC-DC converters

Their durability and thermal performance make them suitable for Colombia’s diverse climate conditions.

How to Choose the Right Ceramic PCB Supplier

When sourcing ceramic PCBs for photovoltaic applications, buyers should consider:

- Proven experience in ceramic PCB manufacturing

- Material options and thermal performance data

- Flexible PCB and rigid-flex integration capability

- Engineering support and DFM review

- Consistent quality and lead-time control

Working with a manufacturer that understands both thermal management and solar industry requirements ensures long-term system reliability.

HOME

HOME