Ceramic Circuit Board Design for the UK Electronics Industry

Table of Contents

- Introduction: Why Ceramic Circuit Board Design Matters

- Understanding Ceramic Circuit Boards

- Key Ceramic Materials Used in the UK Market

- Ceramic Circuit Board Design Principles

- Thermal Management & Reliability Considerations

- Manufacturing Process & DFM for Ceramic PCBs

- Applications Driving Demand in the UK

- Why Choose BST Ceramic PCB

- Conclusion & Next Steps

Ceramic circuit board design has become a critical foundation for high‑reliability electronics in the UK, particularly in sectors such as aerospace, electric vehicles, renewable energy, and industrial automation. Compared with traditional FR‑4 PCBs, ceramic circuit boards offer superior thermal conductivity, electrical insulation, and long‑term stability, making them ideal for harsh operating environments.

For UK engineers and procurement teams, selecting the right ceramic PCB design partner is no longer just about cost—it is about performance, compliance, and lifecycle reliability. This article provides a comprehensive, EEAT‑aligned overview of ceramic circuit board design, integrating best practices from top‑ranking Google results and real manufacturing experience from BST Ceramic PCB.

What Is a Ceramic Circuit Board?

A ceramic circuit board is a type of PCB that uses ceramic materials—rather than epoxy glass—as the substrate. The most common ceramic PCB technologies include:

Thick Film Ceramic PCBs

- Printed conductive pastes on ceramic substrates

- Cost‑effective for medium‑volume production

- Common in power modules and sensors

Thin Film Ceramic PCBs

- High‑precision photolithography

- Excellent line resolution and signal integrity

- Used in RF and microwave applications

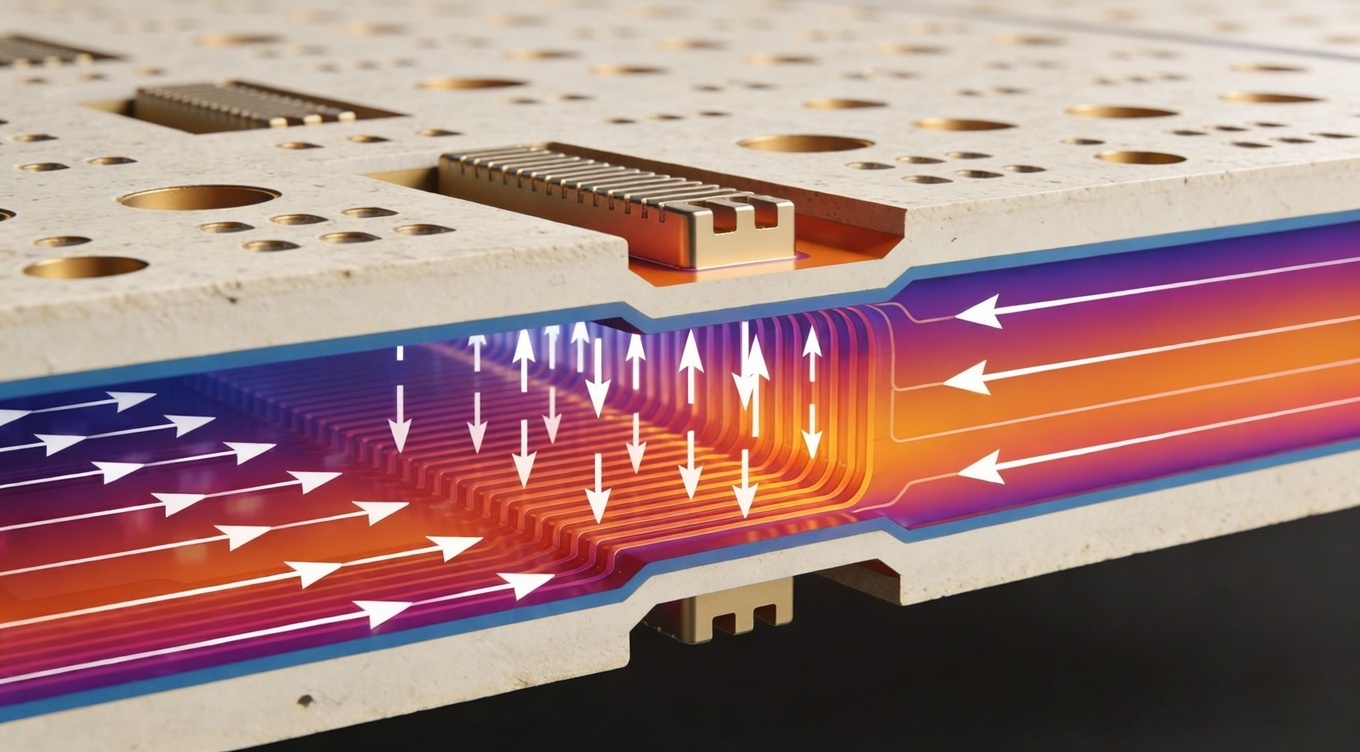

DBC (Direct Bonded Copper) Ceramic PCBs

- Copper bonded directly to ceramic

- Outstanding current‑carrying capacity

- Ideal for power electronics and EV systems

Core Ceramic Materials for UK Applications

Material selection is the cornerstone of ceramic circuit board design. UK customers typically prioritize thermal performance, reliability, and RoHS compliance.

Alumina (Al₂O₃)

- Thermal conductivity: 20–25 W/m·K

- Excellent cost‑performance ratio

- Widely used in industrial and automotive electronics

Aluminum Nitride (AlN)

- Thermal conductivity: up to 170 W/m·K

- Ideal for high‑power and high‑frequency devices

- Popular in aerospace and semiconductor equipment

Silicon Nitride (Si₃N₄)

- High mechanical strength

- Excellent thermal shock resistance

- Emerging choice for next‑generation power modules

Essential Ceramic Circuit Board Design Principles

Designing ceramic circuit boards requires a different mindset compared with standard FR‑4 PCBs.

Layout Optimization

- Minimize thermal resistance paths

- Balance copper distribution to reduce stress

- Avoid sharp corners to prevent crack initiation

Electrical Performance

- Lower dielectric loss for high‑frequency signals

- Stable impedance over temperature

- Suitable for RF and power electronics

Mechanical Reliability

- Match CTE between components and substrate

- Consider solder joint fatigue

- Design for vibration resistance (important for UK rail and aerospace sectors)

Thermal Management & Long‑Term Reliability

Thermal performance is one of the main reasons UK engineers choose ceramic circuit board design. Ceramic substrates dissipate heat more efficiently, reducing junction temperatures and extending component lifespan.

Heat Dissipation Strategies

- Use DBC structures for power density

- Optimize copper thickness and trace width

- Integrate thermal vias and heat spreaders

Reliability Testing

- Thermal cycling

- High‑temperature storage

- Power cycling for automotive compliance

Manufacturing Process & DFM Considerations

A successful ceramic circuit board design must align with manufacturability. At BST Ceramic PCB, design‑for‑manufacturing (DFM) is integrated from the earliest stage.

Process Overview

- Ceramic substrate preparation

- Copper bonding or metallization

- Circuit patterning

- Surface finishing (ENIG, Ag, Au)

- Electrical and reliability testing

Common DFM Challenges

- Micro‑crack prevention

- Copper‑ceramic adhesion control

- Tight tolerance management

Internal Link Suggestion: Link to Ceramic PCB Manufacturing Process page.

Key Applications Driving UK Demand

Ceramic circuit board design is rapidly expanding across multiple UK industries:

Aerospace & Defence

- Radar systems

- Power control units

- Extreme temperature environments

Electric Vehicles & Charging Infrastructure

- Power modules

- Inverters

- On‑board chargers

Industrial & Renewable Energy

- IGBT modules

- Solar inverters

- Wind power control systems

Why UK Customers Choose BST Ceramic PCB

BST Ceramic PCB combines engineering expertise, advanced manufacturing, and export experience to support UK clients from concept to mass production.

Our Strengths

- In‑house ceramic PCB design support

- ISO‑compliant quality management

- Fast prototyping and scalable production

- Proven export experience to the UK and EU

Engineering Collaboration

Our team works closely with UK engineers to optimize ceramic circuit board design for performance, cost, and reliability.

Internal Link Suggestion: Link to Contact Us or Request a Quote page (high‑conversion form).

Conclusion – Start Your Ceramic Circuit Board Design Project

Ceramic circuit board design is no longer a niche technology—it is a strategic enabler for high‑performance electronics in the UK. By choosing the right materials, following proven design principles, and working with an experienced manufacturer like BST Ceramic PCB, UK companies can achieve higher reliability, better thermal performance, and longer product lifecycles.

HOME

HOME