Ceramic PCB Thermal Conductivity: LTCC & HTCC Solutions for Aerospace Applications

Table of Contents

- Introduction: Why Ceramic PCB Thermal Conductivity Matters

- What Is Ceramic PCB Thermal Conductivity?

- Key Materials Affecting Thermal Performance

- LTCC vs HTCC: Thermal Conductivity Comparison

- Aerospace Applications of LTCC and HTCC Ceramic PCBs

- Why Aerospace Industry Demands High Thermal Conductivity

- Ceramic PCB Thermal Solutions for Brazilian Aerospace Market

- Manufacturing Capability & Quality Control (EEAT核心)

- How to Choose the Right Ceramic PCB for Aerospace Projects

- Conclusion & Engineering Support

Introduction: Why Ceramic PCB Thermal Conductivity Matters

In aerospace electronics, thermal management is not an option—it is a critical design requirement. As electronic systems become more compact and power densities continue to increase, traditional PCB materials struggle to dissipate heat efficiently. This is where ceramic PCB thermal conductivity becomes a decisive factor.

Ceramic printed circuit boards, especially LTCC (Low Temperature Co-fired Ceramic) and HTCC (High Temperature Co-fired Ceramic) technologies, offer superior thermal performance, long-term reliability, and stability under extreme operating conditions. These advantages make ceramic PCBs an essential solution for aerospace applications such as avionics, satellite systems, and high-frequency communication modules.

What Is Ceramic PCB Thermal Conductivity?

Thermal conductivity refers to a material’s ability to transfer heat from heat-generating components to the surrounding environment. In ceramic PCBs, heat is dissipated through the ceramic substrate itself rather than relying solely on copper layers or external heat sinks.

Compared with conventional FR4 materials, ceramic substrates provide:

- Significantly higher thermal conductivity

- Lower thermal expansion mismatch with semiconductor devices

- Improved mechanical stability under temperature cycling

These characteristics are especially important for aerospace electronics, where failure caused by thermal stress is unacceptable.

Key Materials Affecting Thermal Performance

Alumina (Al₂O₃) Ceramic Substrates

Alumina ceramic PCBs are widely used due to their balanced performance and cost efficiency. Typical thermal conductivity ranges from 20–30 W/m·K, making them suitable for many aerospace control and monitoring circuits.

Aluminum Nitride (AlN) High Thermal Conductivity Ceramic

For high-power aerospace applications, aluminum nitride ceramic PCBs offer exceptional thermal conductivity, typically 140–180 W/m·K. AlN is ideal for RF modules, power electronics, and mission-critical systems where heat dissipation directly impacts reliability.

Copper & Metallization Influence on Heat Transfer

Beyond the ceramic material itself, metallization layers such as thick copper, DBC, or active metal brazing significantly affect overall thermal performance. Optimized circuit design ensures efficient heat spreading across the ceramic substrate.

LTCC vs HTCC: Thermal Conductivity Comparison

LTCC Thermal Conductivity Characteristics

LTCC technology allows multilayer integration with embedded passive components. Thermal conductivity typically ranges between 3–7 W/m·K, but advanced designs compensate through multilayer heat spreading and compact layouts.

LTCC is especially suitable for:

- RF and microwave aerospace modules

- Miniaturized satellite communication systems

HTCC Thermal Conductivity Characteristics

HTCC ceramic PCBs, often based on alumina or AlN, provide higher thermal conductivity and stronger mechanical properties. HTCC substrates withstand extreme temperatures and harsh aerospace environments.

LTCC vs HTCC: Which Is Better for Aerospace?

The choice between LTCC and HTCC depends on:

- Operating temperature range

- Power density

- Frequency performance requirements

In many aerospace projects, LTCC is preferred for high-frequency integration, while HTCC is selected for high-power thermal management.

Aerospace Applications of LTCC and HTCC Ceramic PCBs

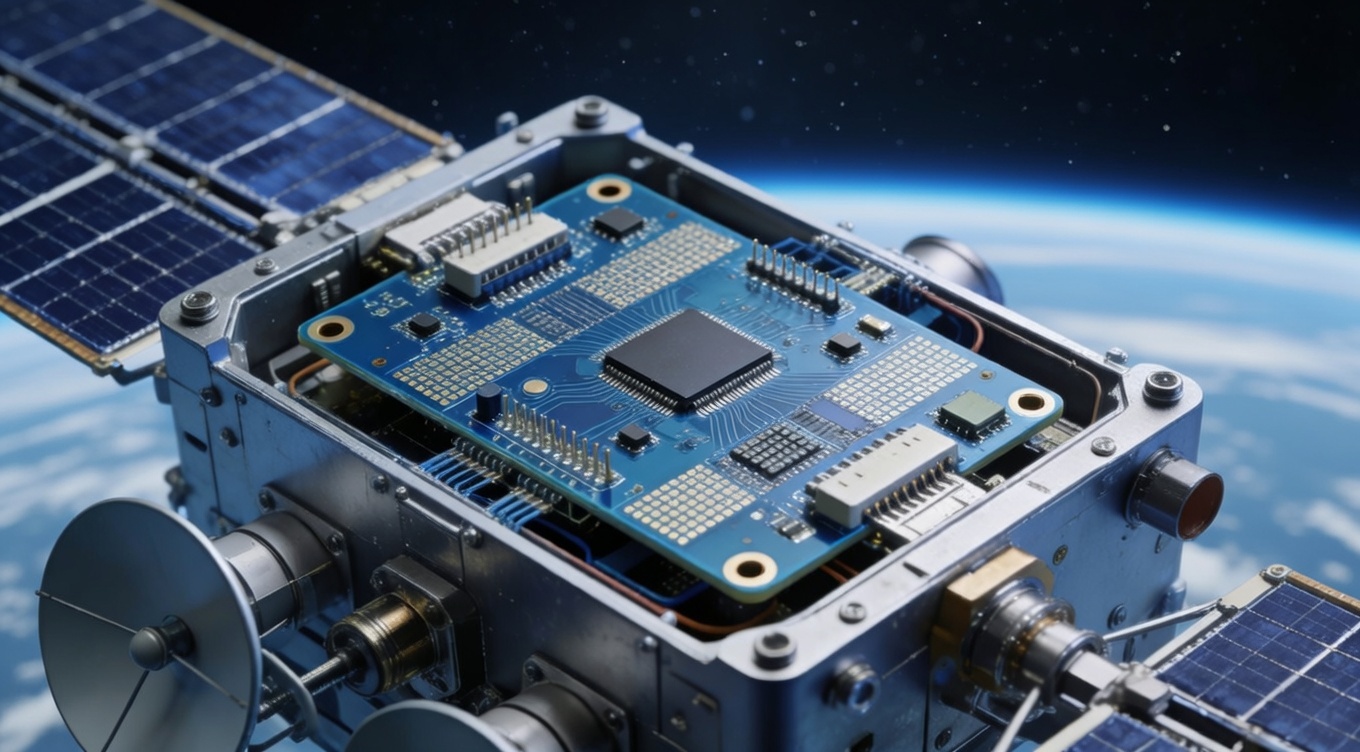

Satellite Communication Modules

Ceramic PCBs enable stable RF performance and efficient thermal dissipation in satellite transceivers and signal processing units.

Avionics Power Control Systems

HTCC ceramic PCBs support power management modules in avionics, ensuring reliability under vibration and temperature cycling.

Radar, RF & Microwave Aerospace Electronics

LTCC ceramic PCBs are widely used in radar and microwave aerospace systems due to their excellent dielectric properties and thermal stability.

Why Aerospace Industry Demands High Thermal Conductivity

Aerospace electronics must operate reliably under:

- Extreme temperature fluctuations

- High altitude and vacuum environments

- Long mission lifecycles without maintenance

High thermal conductivity ceramic PCBs reduce thermal stress, improve component lifespan, and enhance overall system reliability.

Ceramic PCB Thermal Solutions for Brazilian Aerospace Market

Brazil has a rapidly developing aerospace sector, covering aviation manufacturing, satellite programs, and defense electronics. These applications increasingly require high thermal conductivity ceramic PCBs to meet international reliability standards.

As a ceramic PCB manufacturer, BST Ceramic PCB provides customized LTCC and HTCC solutions tailored for Brazilian aerospace clients, supporting both prototype development and volume production.

Manufacturing Capability & Quality Control

Aerospace projects demand strict process control and traceability. From material selection to final inspection, ceramic PCB manufacturing must comply with aerospace-grade quality requirements.

BST Ceramic PCB integrates:

- Experienced ceramic PCB engineering teams

- Advanced firing and metallization processes

- Comprehensive electrical and thermal testing

This ensures consistent performance and long-term reliability in aerospace environments.

How to Choose the Right Ceramic PCB for Aerospace Projects

Selecting the appropriate ceramic PCB involves:

- Defining thermal conductivity requirements

- Evaluating LTCC vs HTCC advantages

- Considering operating environment and lifecycle

Early collaboration with a professional ceramic PCB manufacturer helps optimize design, reduce cost, and shorten development cycles.

Conclusion & Engineering Support

Ceramic PCB thermal conductivity plays a vital role in aerospace electronics design. LTCC and HTCC technologies provide reliable thermal solutions for high-performance aerospace applications.

If you are developing aerospace electronic systems for the Brazilian market, working with an experienced ceramic PCB supplier ensures technical success and long-term reliability.

HOME

HOME