Ceramic Substrate Linewidth and Line Spacing for Power Electronics

Ceramic Substrate Linewidth and Line Spacing: Design Limits and Manufacturing Reality

As power electronics continue to evolve toward higher efficiency, higher power density, and greater reliability, ceramic substrates have become a critical foundation for modern electronic systems. In particular, ceramic substrate linewidth and line spacing play a decisive role in determining electrical performance, thermal stability, and long-term reliability.

For engineers and purchasing teams in Germany—especially in automotive, industrial automation, and renewable energy sectors—understanding the practical limits of ceramic linewidth and spacing is essential. This article provides a realistic, manufacturing-driven perspective on what is achievable today, how design decisions affect production yield, and how to balance performance with cost.

Understanding Linewidth and Line Spacing in Ceramic Substrates

Definition of Linewidth and Line Spacing

Linewidth refers to the width of a conductive trace on a ceramic substrate, while line spacing describes the distance between adjacent traces. Unlike standard FR4 PCBs, ceramic substrates operate under much higher temperatures, voltages, and mechanical stress.

In ceramic PCB manufacturing, linewidth and spacing are influenced not only by design files but also by:

- Metallization method

- Ceramic material properties

- Etching and sintering processes

Why Precision Matters in Power and Automotive Electronics

In high-power applications such as IGBT modules or SiC-based converters, insufficient line spacing can lead to:

-

Electrical breakdown

-

Partial discharge

-

Long-term insulation degradation

German automotive and industrial standards demand consistent electrical clearance, especially for systems operating above 600V or under continuous thermal cycling.

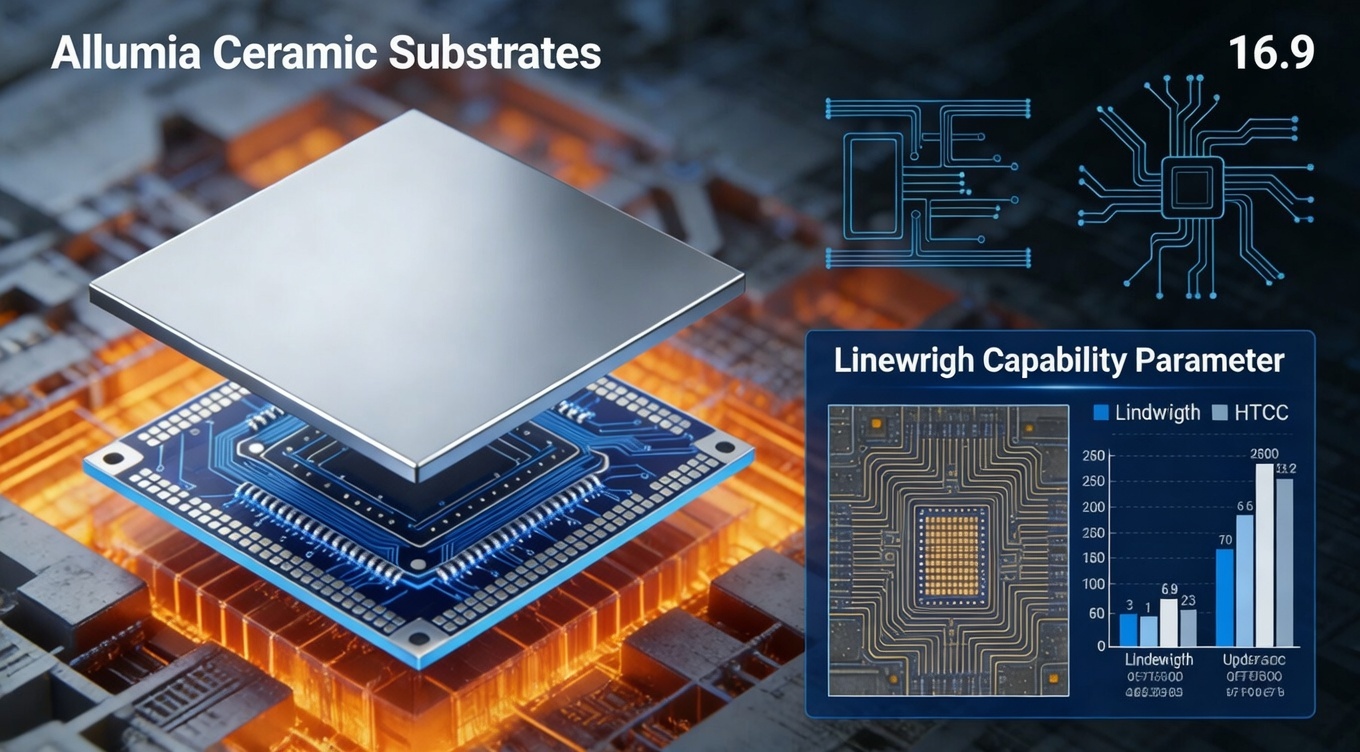

Types of Ceramic Substrates and Their Linewidth Capabilities

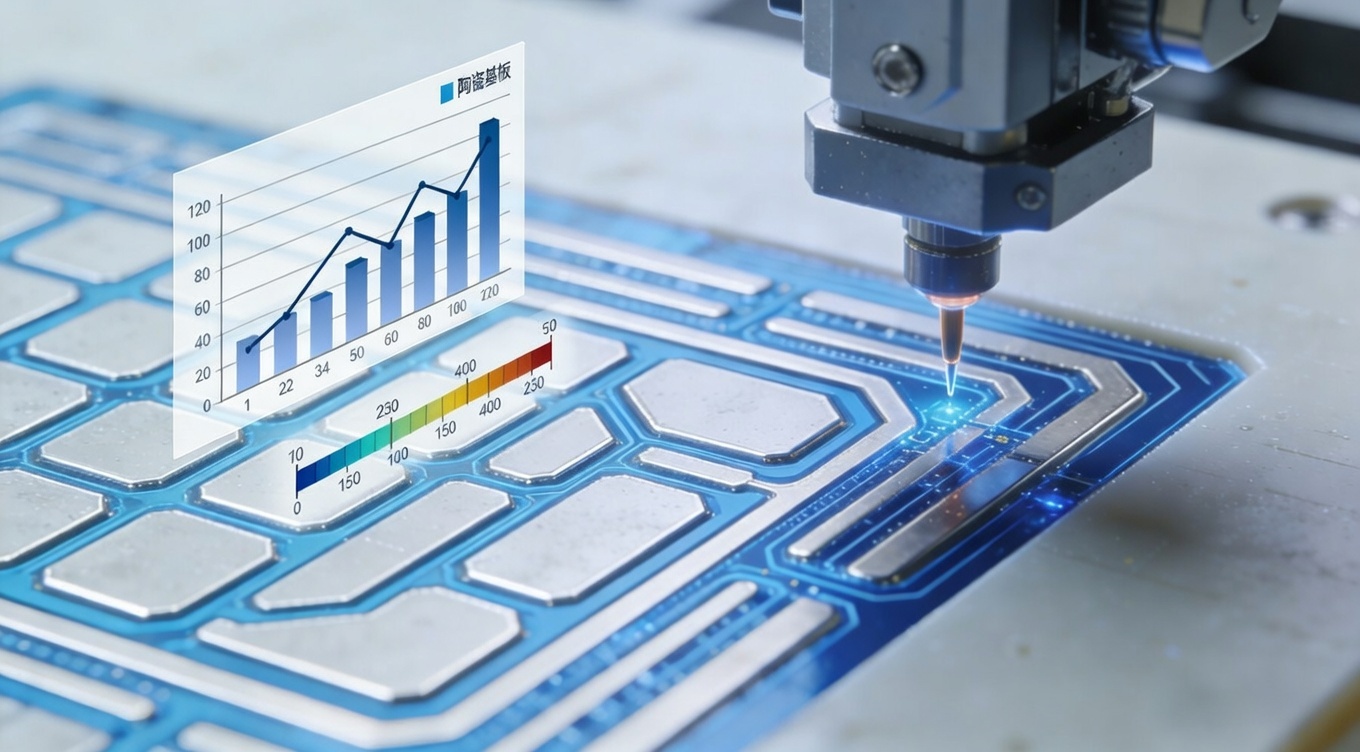

Alumina (Al₂O₃) Ceramic Substrates

Alumina remains the most widely used ceramic substrate due to its cost-effectiveness and stable mechanical properties.

Typical achievable values:

- Minimum linewidth: 100–150 μm

- Minimum line spacing: 100–150 μm

Alumina is commonly used in industrial control, LED modules, and medium-power applications.

Aluminum Nitride (AlN) Ceramic Substrates

AlN offers superior thermal conductivity, making it ideal for high-power density designs.

Typical achievable values:

- Minimum linewidth: 120–150 μm

- Minimum line spacing: 120–150 μm

Due to its higher material cost and processing complexity, AlN designs often prioritize reliability over extreme miniaturization.

DBC, DPC, and AMB Technology Comparison

| Technology | Typical Linewidth | Typical Spacing | Application Focus |

|---|---|---|---|

| DBC | ≥300 μm | ≥300 μm | High current modules |

| DPC | ≥80–100 μm | ≥80–100 μm | High precision circuits |

| AMB | ≥200 μm | ≥200 μm | Automotive power modules |

Among these, DPC ceramic substrates provide the highest precision, while DBC and AMB prioritize current handling and thermal robustness.

Manufacturing Factors Affecting Ceramic Linewidth and Spacing

Metallization Methods and Etching Precision

Copper thickness, adhesion layers, and etching chemistry directly affect edge definition. In high-precision ceramic PCB manufacturing, maintaining clean trace edges is often more challenging than achieving nominal linewidth.

BST Ceramic PCB applies controlled photolithography and etching processes to ensure consistent trace geometry across production batches.

Substrate Flatness and Thermal Stability

Ceramic substrates undergo high-temperature sintering, which can introduce micro-deformation. Poor flatness may cause:

- Uneven copper thickness

- Localized spacing reduction

- Stress concentration during assembly

Proper material selection and process control are essential to maintain spacing integrity.

Yield Control and Mass Production Consistency

Designs with extremely narrow spacing may work in prototypes but suffer from low yield in volume production. For German OEMs, stable mass production often outweighs marginal gains in miniaturization.

Design Guidelines for Optimizing Linewidth and Line Spacing

Electrical Performance Considerations

When defining ceramic linewidth:

- Wider traces reduce resistive losses

- Adequate spacing prevents arcing and EMI issues

Designers should align trace geometry with actual operating voltage, not theoretical limits.

Thermal and Mechanical Reliability

Narrow traces experience higher thermal stress under current load. For power modules, slightly increasing linewidth often improves lifetime performance without significantly increasing substrate size.

Compliance with IPC and Automotive Standards

Common references include:

- IPC-2221 (Generic PCB Design)

- IPC-6012DA (High Reliability Applications)

- Automotive OEM internal standards

BST Ceramic PCB supports design reviews aligned with European and automotive compliance requirements.

Typical Applications in the German Market

Automotive Power Modules

Ceramic substrates are widely used in:

- Inverters

- On-board chargers

- DC-DC converters

Line spacing is especially critical for high-voltage isolation and long-term reliability.

Industrial Power Electronics

Applications include:

- Motor drives

- Power supplies

- Industrial automation systems

Here, robust spacing often takes priority over ultra-fine linewidth.

Renewable Energy and EV Charging Systems

Solar inverters and EV chargers require ceramic substrates capable of withstanding high voltage and outdoor thermal cycling, making conservative spacing a preferred design choice.

Why Choose BST Ceramic PCB for High-Precision Ceramic Substrates

Manufacturing Capability Overview

BST Ceramic PCB specializes in:

- Alumina and AlN ceramic substrates

- DPC, DBC, and AMB technologies

- Precision linewidth and spacing control

Our engineering team supports design-for-manufacturing (DFM) analysis to balance performance and yield.

Quality Control and Engineering Support

From prototype to mass production, BST implements:

- Process traceability

- Electrical and visual inspection

- Reliability-focused design feedback

Conclusion: Balancing Design Ambition and Manufacturing Reality

Achieving optimal ceramic substrate linewidth and line spacing is not about pushing theoretical limits, but about aligning design intent with manufacturing reality. For German manufacturers focused on reliability, safety, and long product lifecycles, a well-balanced approach delivers the best results.

By combining engineering expertise with controlled manufacturing processes, BST Ceramic PCB helps customers translate design concepts into reliable, scalable ceramic substrate solutions.

HOME

HOME