High-Temperature Resistant Ceramic PCB Solutions for Industrial LTCC and HTCC Applications

Quick Navigation

- What Is a High-Temperature Resistant Ceramic PCB?

- Why LTCC and HTCC PCBs Dominate High-Temperature Industrial Applications

- Key Industrial Applications of High-Temperature Ceramic PCBs

- LTCC vs HTCC PCB: Performance Comparison in Harsh Environments

- Material Choices: Alumina, Aluminum Nitride, and Beyond

- Manufacturing Challenges and Design Considerations

- Why High-Temperature Ceramic PCBs Matter for Ukraine’s Industrial Market

- BST Ceramic PCB: Proven Expertise in LTCC & HTCC Manufacturing

- How to Select the Right High-Temperature Ceramic PCB Supplier

As industrial electronics continue to operate under harsher conditions, the demand for high-temperature resistant ceramic PCB solutions has grown significantly. In sectors such as energy infrastructure, industrial automation, automotive electronics, and defense systems, conventional organic PCBs struggle to deliver long-term reliability.

Ceramic PCB technologies—especially LTCC PCB and HTCC PCB—have become the preferred choice for applications requiring stable electrical performance at elevated temperatures.

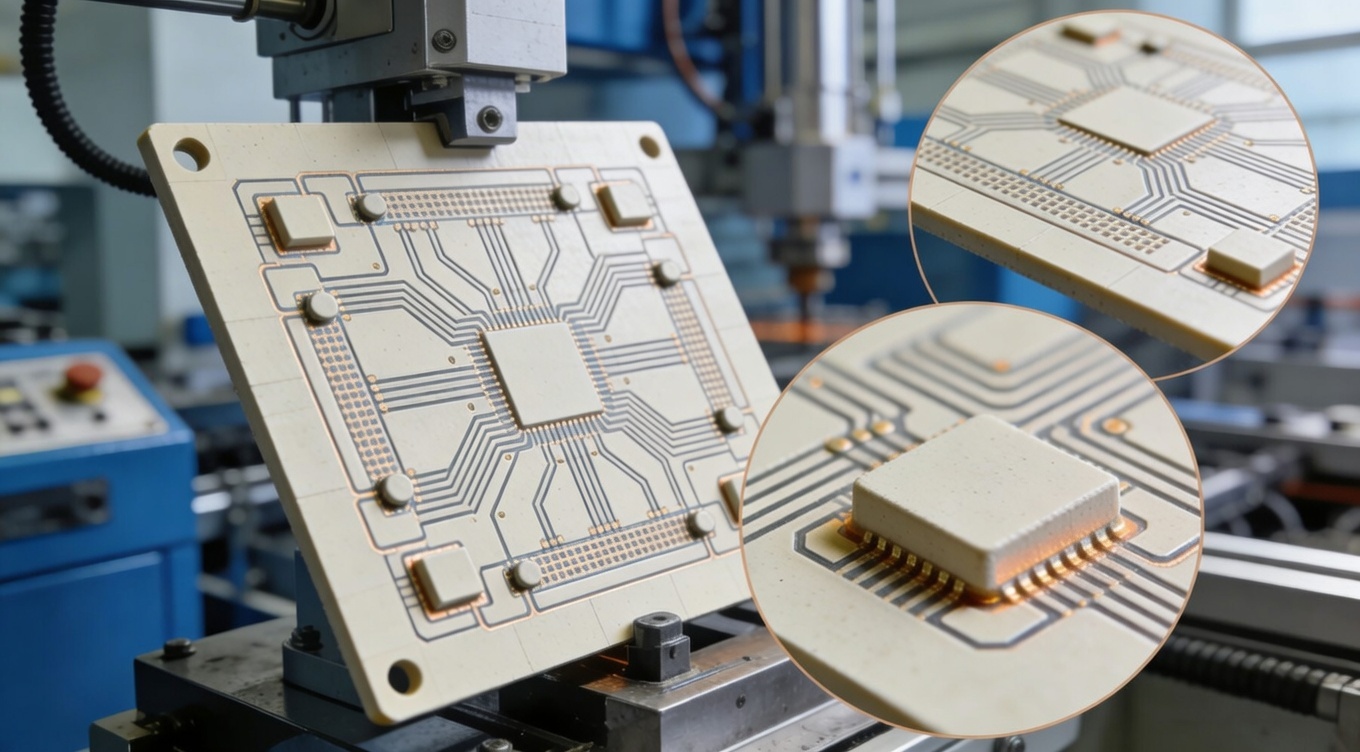

What Is a High-Temperature Resistant Ceramic PCB?

A high-temperature resistant ceramic PCB is a circuit board manufactured using ceramic substrates such as alumina or aluminum nitride. Unlike traditional FR4 materials, ceramic substrates maintain structural integrity, electrical insulation, and thermal performance when exposed to temperatures exceeding 200°C.

Why Standard FR4 PCBs Fail at High Temperatures

FR4 materials degrade rapidly under thermal stress. Delamination, dielectric breakdown, and copper trace failure are common issues in industrial environments. Ceramic PCBs eliminate these risks by offering low thermal expansion and excellent heat dissipation.

Why LTCC and HTCC PCBs Dominate High-Temperature Industrial Applications

LTCC PCB Technology

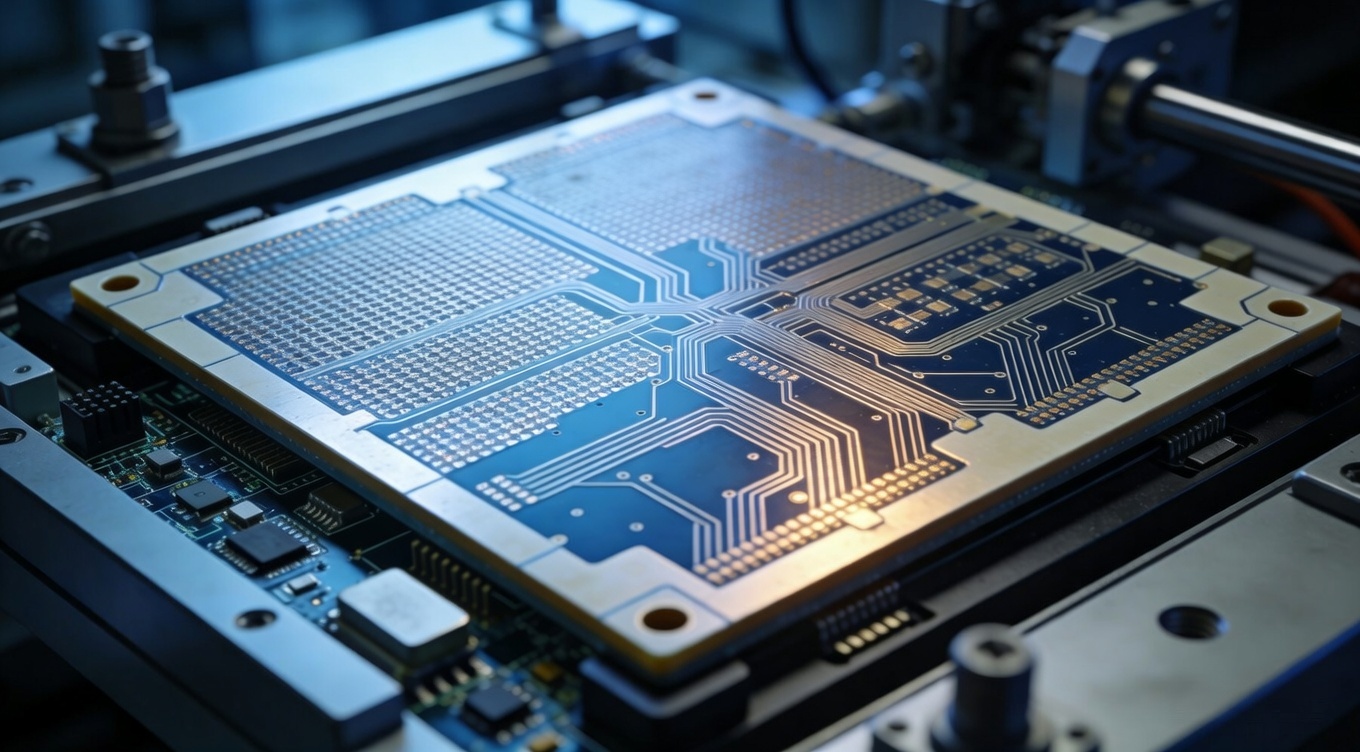

Low Temperature Cofired Ceramic (LTCC) PCBs are manufactured at approximately 850°C, allowing the integration of conductive materials such as silver and copper. LTCC PCBs are ideal for multilayer designs, compact modules, and applications requiring embedded passive components.

HTCC PCB Technology

High Temperature Cofired Ceramic (HTCC) PCBs are fired above 1600°C and typically use tungsten or molybdenum conductors. HTCC PCBs deliver superior mechanical strength and are suitable for extremely harsh environments, including high-voltage and high-power applications.

Key Industrial Applications of High-Temperature Ceramic PCBs

Industrial Automation and Power Control

Ceramic PCBs are widely used in motor drives, power converters, and industrial sensors, where temperature fluctuations and long operating cycles are unavoidable.

Energy and Power Infrastructure

In renewable energy systems, ceramic PCBs ensure stable performance in inverters, power modules, and grid-control electronics.

Automotive and Heavy Transportation

Electric vehicles, rail systems, and heavy machinery rely on LTCC and HTCC PCBs for control units exposed to continuous thermal stress.

Defense and Aerospace

Mission-critical electronics demand materials that can withstand extreme temperatures, vibration, and long service life—conditions where ceramic PCBs outperform organic alternatives.

LTCC vs HTCC PCB: Performance Comparison

| Feature | LTCC PCB | HTCC PCB |

|---|---|---|

| Firing Temperature | ~850°C | >1600°C |

| Typical Conductors | Ag, Cu | W, Mo |

| Mechanical Strength | Medium | Very High |

| Application Focus | Compact modules | High power & harsh environments |

Material Choices: Alumina and Aluminum Nitride

Alumina ceramic PCBs offer a cost-effective solution for most high-temperature applications, while aluminum nitride ceramic PCBs provide exceptional thermal conductivity for power electronics requiring rapid heat dissipation.

Manufacturing Challenges and Design Considerations

Precision in line width and line spacing, multilayer alignment, and thermal expansion matching is critical. Advanced ceramic PCB manufacturers perform reliability testing to ensure long-term performance in industrial conditions.

Why High-Temperature Ceramic PCBs Matter for Ukraine’s Industrial Market

Ukraine’s industrial, energy, and infrastructure sectors increasingly demand durable electronic solutions. High-temperature resistant ceramic PCBs help reduce system failures, maintenance costs, and downtime—key factors for industrial recovery and modernization.

BST Ceramic PCB: Proven Expertise in LTCC & HTCC Manufacturing

BST Ceramic PCB specializes in LTCC and HTCC PCB design, prototyping, and mass production, supporting global industrial clients with consistent quality and engineering support.

All products undergo strict quality control aligned with international standards, ensuring reliable performance in high-temperature applications.

How to Select the Right High-Temperature Ceramic PCB Supplier

Industrial buyers should evaluate suppliers based on:

- Proven LTCC and HTCC manufacturing experience

- Material traceability and testing capability

- Engineering support and design-for-manufacturing expertise

Choosing the right partner directly impacts system reliability and lifecycle cost.

HOME

HOME