Ceramic PCB for Power Modules (IGBT) in Australia — Technical Standards, Thermal Solutions, and Supplier Strategy

As Australia accelerates investment in renewable energy, industrial electrification, and high-efficiency power conversion systems, IGBT-based power modules have become a core component across multiple sectors. From solar inverters and industrial motor drives to EV charging infrastructure, these systems operate under high current, high voltage, and continuous thermal stress.

In this context, ceramic PCB for power modules (IGBT) is no longer a niche solution. It is a critical enabling technology that directly determines system reliability, thermal performance, and service life — especially under Australia’s demanding operating environments.

This article provides an in-depth, engineering-driven analysis of ceramic PCBs used in IGBT power modules for the Australian market, covering technical requirements, material and process choices, application scenarios, and why BSTCERAMICPCB is a reliable partner for Australian power electronics projects.

Understanding Ceramic PCBs in IGBT Power Modules — Why They Matter in Australia

IGBT power modules generate significant heat during switching and continuous operation. In Australia, where many power electronics systems operate in high ambient temperatures, outdoor installations, or remote industrial sites, thermal management becomes a first-order design constraint rather than an afterthought.

Traditional organic substrates such as FR-4 or metal-core PCBs struggle to meet these requirements due to limited thermal conductivity and long-term reliability issues. Ceramic PCBs, particularly those based on alumina or aluminum nitride with thick copper metallization, address these limitations directly.

What Makes Ceramic PCB Essential for IGBT Power Modules

A ceramic PCB used in an IGBT module must simultaneously provide:

- Efficient heat dissipation from the semiconductor junction

- High electrical insulation at elevated voltages

- Mechanical stability under thermal cycling and vibration

Ceramic substrates inherently offer superior dielectric strength and thermal stability compared to organic materials. When combined with processes such as Direct Bonded Copper (DBC) or Active Metal Brazing (AMB), they enable thick copper layers capable of handling high current without excessive resistive loss.

Thermal and Electrical Challenges in Australian Power Electronics

Australian power electronics applications often face:

- Elevated ambient temperatures

- Long duty cycles with minimal downtime

- Exposure to dust, humidity, and vibration

These conditions accelerate material fatigue and thermal degradation. Ceramic PCBs mitigate these risks by maintaining stable thermal performance over long service periods, making them particularly suitable for solar inverters, mining equipment, and industrial drives widely used across Australia.

High-Power Module Reliability Under Harsh Conditions

For Australian system integrators, reliability is closely tied to maintenance cost and system uptime. A ceramic PCB designed specifically for IGBT power modules reduces:

- Solder joint fatigue

- Delamination risk

- Thermal runaway scenarios

This is why ceramic PCB adoption in Australian IGBT modules continues to increase across both utility-scale and industrial applications.

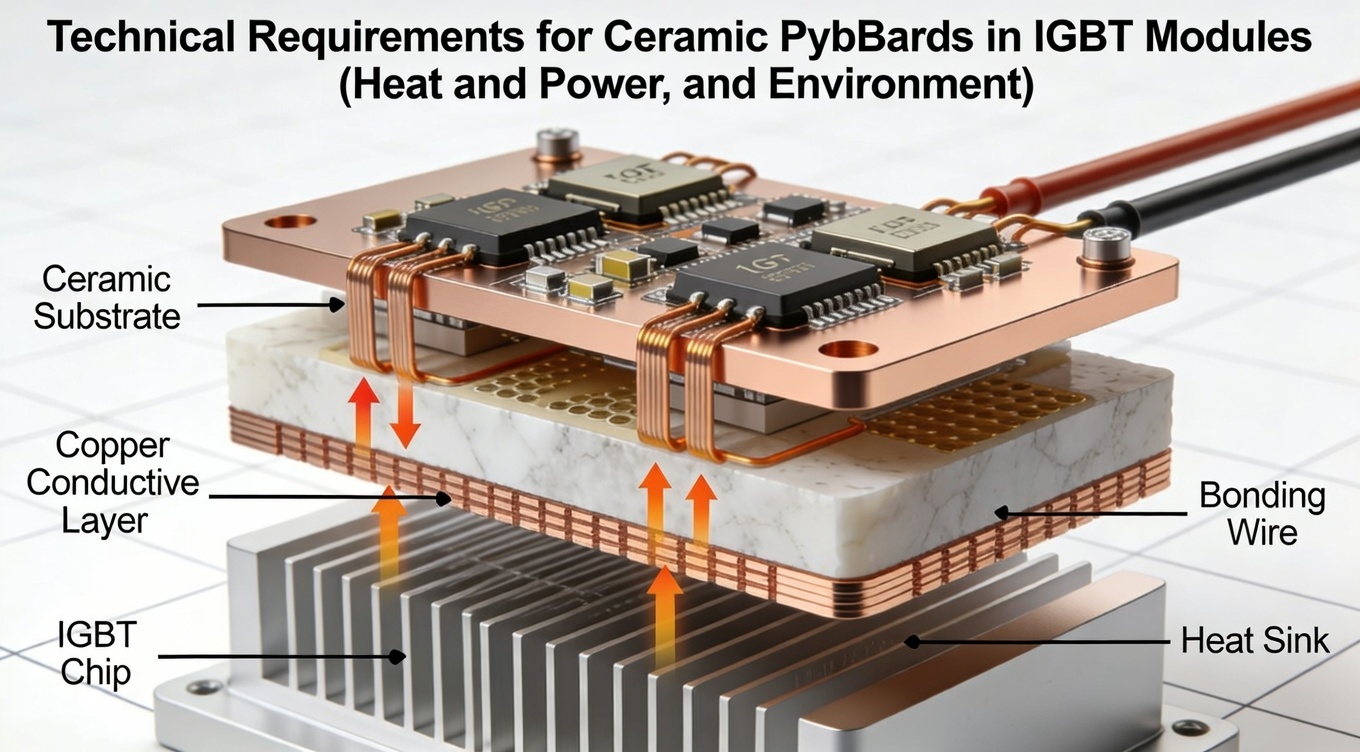

Technical Requirements for Ceramic PCBs in IGBT Modules (Heat, Power, and Environment)

Designing a ceramic PCB for IGBT power modules requires meeting a set of non-negotiable technical requirements, particularly for the Australian market where systems are often expected to operate continuously for years.

Thermal Dissipation and High Current Handling

Thermal performance is the primary driver behind ceramic PCB selection. Key requirements include:

- Low thermal resistance from IGBT junction to heatsink

- Capability to support thick copper layers (≥300 μm)

- Stable heat spreading under pulsed and continuous loads

Ceramic substrates such as alumina and aluminum nitride provide a solid thermal pathway, while DBC or AMB copper layers enable efficient current conduction without excessive Joule heating.

Electrical Insulation and Dielectric Performance

IGBT modules often operate at hundreds or thousands of volts. Ceramic PCBs must ensure:

- High dielectric strength

- Low leakage current

- Stable insulation even at elevated temperatures

These properties are critical for compliance with Australian electrical safety expectations and for preventing premature system failure.

CTE Matching, Mechanical Stability, and Vibration Resistance

Mismatch in coefficient of thermal expansion (CTE) between substrate, copper, and semiconductor devices can lead to mechanical stress. Ceramic PCBs reduce this risk by offering:

- Better CTE compatibility with IGBT chips

- High stiffness and dimensional stability

This is especially important for Australian mining and industrial applications where vibration and mechanical shock are common.

Quality and Compliance Expectations in Australia

While Australia does not impose a single automotive-style certification for power electronics, customers typically expect:

- Consistent manufacturing quality

- Material traceability

- Documented process control

BSTCERAMICPCB integrates these requirements into its ceramic PCB manufacturing process, ensuring suitability for Australian industrial and energy projects.

Core Ceramic PCB Technologies for IGBT Power Modules

Not all ceramic PCBs are equal. The choice of manufacturing technology significantly influences thermal performance, reliability, and cost.

Direct Bonded Copper (DBC) vs Active Metal Brazing (AMB)

DBC ceramic PCBs are widely used in IGBT modules due to:

- Strong copper-to-ceramic bonding

- Excellent thermal conductivity

- Proven long-term reliability

AMB ceramic PCBs provide enhanced bonding strength and are often selected for:

- High-power density designs

- Modules exposed to extreme thermal cycling

BSTCERAMICPCB supports both DBC and AMB processes, allowing Australian customers to select the most appropriate solution based on power level, environment, and cost structure.

Thick Copper and Heavy-Current Design Considerations

IGBT power modules demand copper layers capable of handling high current without excessive loss. Ceramic PCBs enable:

- Thick copper traces

- Optimized current paths

- Reduced parasitic resistance

These characteristics directly improve system efficiency and reduce thermal stress on power devices.

Process Control and Long-Term Reliability

Ceramic PCB reliability depends heavily on process stability:

- Uniform copper thickness

- Controlled bonding interfaces

- Consistent ceramic substrate quality

BSTCERAMICPCB applies strict process controls and inspection protocols to ensure that ceramic PCBs used in Australian IGBT applications meet long-term performance expectations.

Key Australian IGBT Applications and Industry-specific Solutions

The demand for ceramic PCB for power modules (IGBT) in Australia is driven by several high-growth sectors.

Renewable Energy and Solar Inverters

Australia’s large-scale solar installations rely heavily on IGBT-based inverters. Ceramic PCBs enable:

- Efficient heat dissipation in high-power inverter stages

- Compact module design

- Long service life under outdoor conditions

Industrial Drives and Motor Control Systems

In mining, manufacturing, and water infrastructure, IGBT modules are used in:

- Variable frequency drives

- Motor control units

- High-power converters

Ceramic PCBs ensure stable operation despite high loads and harsh environments.

EV Chargers and Electrified Transport

As EV infrastructure expands across Australia, ceramic PCBs support:

- Fast-charging systems

- High-voltage power stages

- Compact, thermally efficient charger designs

Harsh Environment Performance Expectations

Across all these sectors, Australian customers prioritize:

- Durability

- Minimal maintenance

- Predictable long-term performance

Ceramic PCBs address these priorities more effectively than organic alternatives.

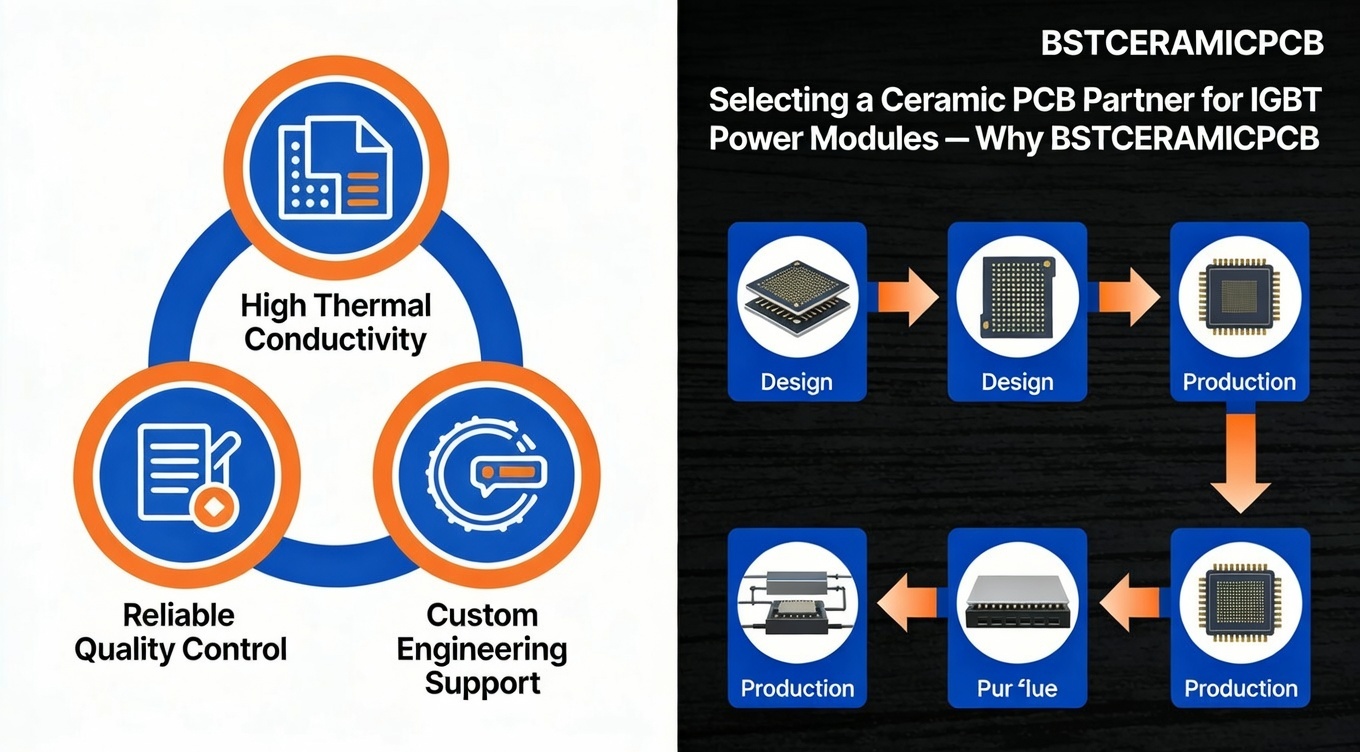

Selecting a Ceramic PCB Partner for IGBT Power Modules — Why BSTCERAMICPCB

Choosing the right supplier is as important as choosing the right technology. For Australian customers, BSTCERAMICPCB stands out through a combination of engineering expertise and manufacturing reliability.

Engineering Support and Customization

BSTCERAMICPCB provides:

- Material and process recommendations

- Design review for thermal and electrical optimization

- Prototyping support before volume production

This approach reduces risk and shortens development cycles.

Quality Control and Supply Chain Assurance

BSTCERAMICPCB implements:

- Incoming material inspection

- In-process quality control

- Final electrical and visual inspection

Ensuring consistent quality for Australian customers across pilot and production runs.

Long-term Partnership Value

Rather than acting as a transactional supplier, BSTCERAMICPCB supports:

- Design iteration

- Scaling from prototype to mass production

- Long-term project continuity

This partnership mindset aligns well with the expectations of Australian industrial and energy customers.

Start Your IGBT Ceramic PCB Project with BSTCERAMICPCB

For Australian power electronics applications, ceramic PCB for power modules (IGBT) is a strategic design choice that directly impacts system reliability, efficiency, and lifetime cost.

BSTCERAMICPCB delivers:

- DBC and AMB ceramic PCBs for IGBT modules

- Proven thermal management solutions

- Engineering-driven support from concept to production

Contact BSTCERAMICPCB today to discuss your IGBT power module requirements and receive a tailored ceramic PCB solution for the Australian market.

HOME

HOME