Automotive-grade Aluminum Nitride Substrate in Europe — Technical Specifications, Applications, and Supplier Selection

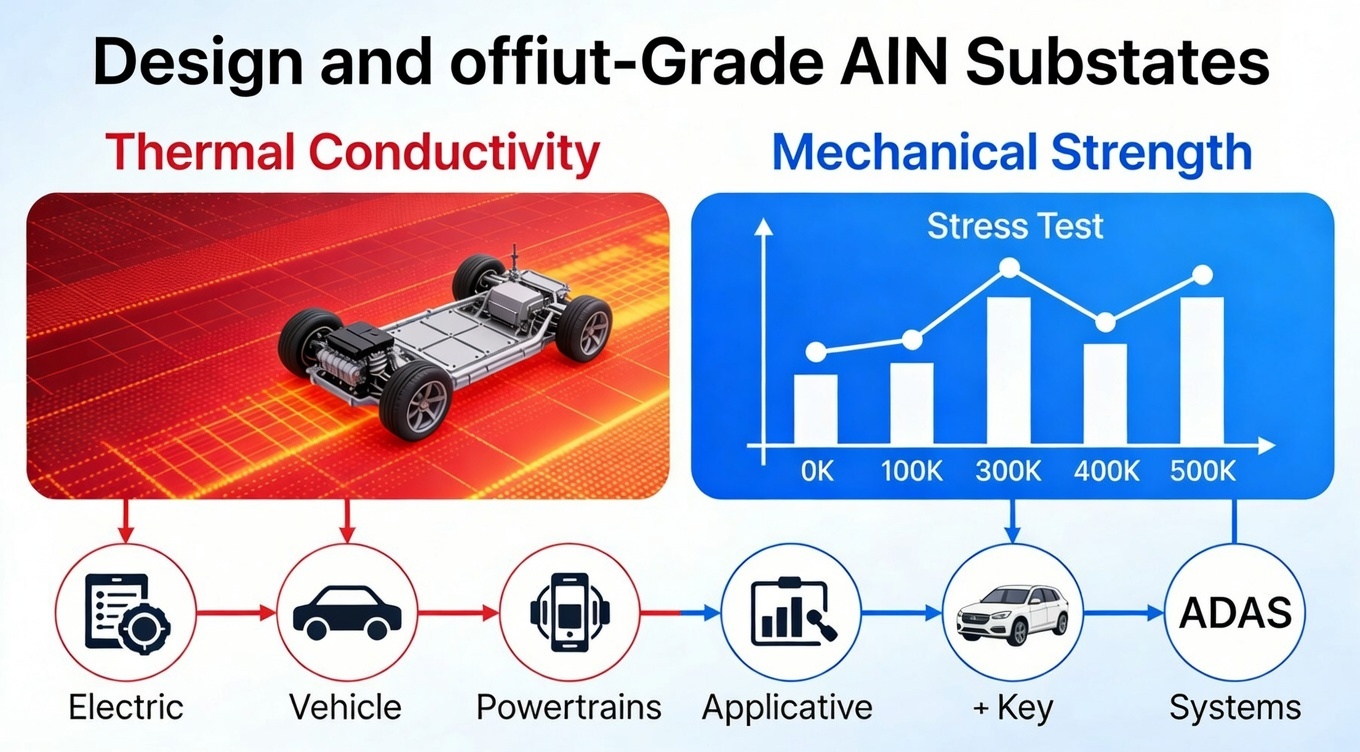

As Europe accelerates toward vehicle electrification, advanced driver-assistance systems (ADAS), and high-power automotive electronics, automotive-grade aluminum nitride (AlN) substrate has become a critical material in next-generation ceramic PCB solutions. Compared with conventional substrates, AlN delivers unmatched thermal conductivity, electrical insulation, and long-term reliability—attributes that align precisely with Europe’s stringent automotive standards and performance expectations.

For European OEMs and Tier-1 suppliers, selecting an automotive-grade AlN substrate is no longer a material decision alone. It is a system-level engineering choice that directly impacts thermal management, safety compliance, lifetime cost, and vehicle reliability.

This article provides a comprehensive, engineering-focused analysis of automotive-grade aluminum nitride substrates for the European market, including technical requirements, industry applications, selection criteria, and why BSTCERAMICPCB is a trusted partner for European automotive ceramic PCB projects.

Introduction to Automotive-grade Aluminum Nitride Substrate and European Market Dynamics

Europe’s automotive electronics ecosystem is evolving rapidly. Electrified drivetrains, high-voltage power modules, and compact electronic control units are driving unprecedented thermal and reliability challenges. Under these conditions, traditional organic substrates and even standard ceramic materials increasingly fall short.

Automotive-grade aluminum nitride substrate stands out because it addresses three core European priorities simultaneously: thermal efficiency, safety compliance, and durability over extended lifecycles.

With thermal conductivity typically exceeding 170 W/m·K, AlN substrates enable efficient heat dissipation from high-power semiconductor devices such as SiC MOSFETs and IGBTs. This is especially relevant for European EV platforms, where compact packaging and long driving ranges require optimal thermal performance without increasing system size or cooling complexity.

From a market perspective, Europe’s demand is driven by:

- EV power electronics (inverters, onboard chargers, DC-DC converters)

- ADAS and autonomous driving modules

- Power-dense auxiliary automotive electronics

European OEMs also impose stricter requirements on process consistency, traceability, and supplier accountability. Automotive-grade AlN substrates must not only meet performance targets but also demonstrate stable quality under IATF 16949-aligned manufacturing systems.

BSTCERAMICPCB supports this evolving landscape by supplying automotive-grade aluminum nitride ceramic substrates and AlN-based ceramic PCBs specifically engineered for European automotive applications, ensuring performance alignment from prototype to mass production.

Technical Requirements and Standards for Automotive-grade AlN Substrates in Europe

European automotive applications impose some of the most demanding technical requirements globally. An automotive-grade aluminum nitride substrate must perform consistently under electrical, thermal, and mechanical stress for more than a decade of operation.

Thermal Performance and Heat Dissipation

Thermal management is the primary reason AlN is adopted in automotive systems. European EV and hybrid platforms require substrates that:

- Rapidly transfer heat from power devices

- Maintain thermal stability across −40°C to +150°C (and beyond)

- Prevent hot spots that reduce semiconductor lifetime

AlN’s thermal conductivity, combined with its low coefficient of thermal expansion (CTE), enables reliable integration with silicon and silicon carbide devices. This minimizes thermo-mechanical stress during thermal cycling, a critical factor in meeting European reliability expectations.

Electrical Insulation and Dielectric Strength

In high-voltage automotive systems, electrical isolation is non-negotiable. Automotive-grade AlN substrates provide:

- High dielectric strength

- Low dielectric loss at elevated temperatures

- Stable insulation under long-term voltage bias

These properties are essential for EV traction inverters, onboard chargers, and high-voltage DC-DC converters used throughout Europe.

Mechanical Strength and Environmental Resistance

European automotive electronics must withstand:

- Continuous vibration

- Mechanical shock

- Thermal cycling and humidity exposure

Automotive-grade AlN substrates manufactured with controlled sintering and surface finishing offer superior mechanical stability compared to lower-grade ceramics.

Compliance with European Automotive Standards

European customers expect alignment with:

- IATF 16949 quality management principles

- EU RoHS and REACH regulations

- Automotive PPAP-style documentation and traceability

BSTCERAMICPCB integrates these compliance requirements into its manufacturing workflow, providing European automotive customers with process transparency, lot traceability, and stable long-term supply assurance.

Application-specific Considerations in European Automotive Electronics

The adoption of automotive-grade aluminum nitride substrates in Europe is application-driven rather than generic. Each automotive system places unique demands on substrate design and processing.

EV Power Modules and Inverters

In traction inverters and power modules, AlN substrates enable:

- Higher power density without overheating

- Reduced cooling system size and complexity

- Improved overall system efficiency

European EV platforms benefit directly from AlN’s ability to manage high switching frequencies and elevated junction temperatures.

On-Board Chargers and DC-DC Converters

Compact onboard chargers require substrates that combine:

- High thermal conductivity

- Strong electrical insulation

- Long-term stability under continuous operation

AlN substrates allow European designers to meet packaging constraints while maintaining performance and safety margins.

ADAS, Radar, and Automotive Sensors

Advanced driver-assistance systems rely on stable electronic performance across wide temperature ranges. Automotive-grade AlN substrates provide:

- Consistent electrical behavior

- Low thermal drift

- Mechanical reliability for sensor modules

This makes AlN an increasingly preferred material for European ADAS and sensor platforms.

Design Constraints and Integration Challenges

European automotive engineers must balance:

- Performance vs. cost

- Size vs. thermal capability

- Reliability vs. manufacturability

BSTCERAMICPCB supports this process by offering engineering consultation, ensuring that AlN substrate thickness, metallization, and layout are optimized for each specific automotive application.

Design Trade-offs and Selection Criteria for Automotive-grade AlN Substrates

Selecting an automotive-grade aluminum nitride substrate involves evaluating multiple trade-offs rather than choosing the highest specification material blindly.

AlN vs Alumina and Other Ceramic Substrates

While alumina remains suitable for lower-power automotive electronics, it cannot match AlN in:

- Thermal conductivity

- Power density capability

- Advanced EV and high-voltage applications

For European platforms focused on electrification and performance, AlN increasingly represents the optimal balance of performance and reliability.

Metallization and Process Options

Automotive-grade AlN substrates are typically combined with:

- DBC (Direct Bonded Copper) for high-current applications

- DPC (Direct Plated Copper) for fine-line, high-precision circuits

Each process affects thermal resistance, current handling, and long-term reliability. BSTCERAMICPCB offers both DBC and DPC solutions, enabling European customers to select the most appropriate configuration.

Reliability vs Cost Considerations

European automotive programs prioritize total lifecycle cost, not lowest unit price. An automotive-grade AlN substrate reduces:

- Failure rates

- Warranty risk

- System redesign costs

BSTCERAMICPCB helps customers evaluate these trade-offs with data-driven recommendations rather than generic sales claims.

Why European Automotive Customers Choose BSTCERAMICPCB

For European automotive projects, supplier selection is as critical as material selection. BSTCERAMICPCB is chosen because it aligns with European engineering expectations, not just pricing targets.

Engineering-led Collaboration

BSTCERAMICPCB supports European customers with:

- Material selection guidance

- Process feasibility reviews

- Rapid prototyping for validation

This reduces development risk and shortens time-to-market.

Automotive-grade Manufacturing and Quality Control

BSTCERAMICPCB applies:

- Controlled AlN substrate sourcing

- Stable sintering and metallization processes

- Full inspection and traceability

This ensures consistency across pilot and volume production.

Long-term Partnership Approach

European automotive customers value suppliers that support:

- Multi-year programs

- Design revisions

- Volume scaling

BSTCERAMICPCB positions itself as a long-term ceramic PCB partner, not a transactional vendor.

Start Your Automotive-grade AlN Substrate Project with BSTCERAMICPCB

Choosing an automotive-grade aluminum nitride substrate is a strategic engineering decision that affects performance, safety, and lifecycle cost. For European automotive applications, success depends on material expertise, process control, and supplier accountability.

BSTCERAMICPCB delivers:

- Automotive-grade AlN substrates

- DBC and DPC ceramic PCB solutions

- Engineering support aligned with European standards

Contact BSTCERAMICPCB today to discuss your automotive project and receive an engineering-based recommendation tailored to European requirements.

HOME

HOME