Ceramic Circuit Board Material Explained: How to Choose the Right Ceramic PCB for High-Power Applications

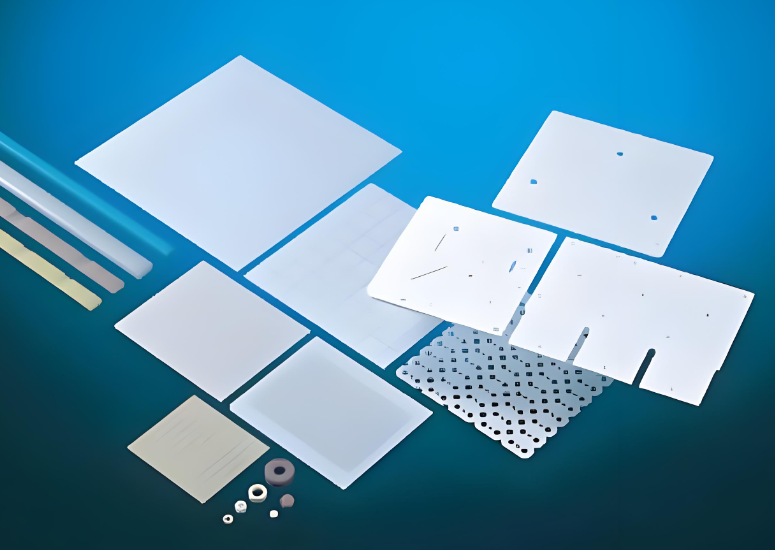

Ceramic circuit board material is the preferred substrate solution for high-power, high-temperature, and high-reliability electronics. By combining excellent thermal conductivity, electrical insulation, and long-term stability, ceramic PCB material has become essential for applications where FR4 can no longer meet thermal or reliability requirements.

As a professional ceramic circuit board material manufacturer, Bstceramic helps engineers and procurement teams select the right ceramic PCB substrate from the earliest design stage, reducing thermal risk, avoiding over-engineering, and shortening time to market.

What Is Ceramic Circuit Board Material and Why Is It Used?

A ceramic circuit board material is a ceramic-based PCB substrate designed to replace FR4 in power electronics where heat dissipation, voltage isolation, and reliability are critical. In practical engineering terms, ceramic PCB material is chosen when thermal limits, not circuit complexity, define system performance.

- High thermal conductivity for efficient heat dissipation

- Excellent dielectric strength for high-voltage applications

- Low coefficient of thermal expansion to reduce solder joint stress

- Outstanding thermal and chemical stability

Which Types of Ceramic Circuit Board Material Are Most Common?

The ceramic PCB market is mainly dominated by Alumina and Aluminum Nitride ceramic substrates.

| Ceramic PCB Material | Thermal Conductivity (W/m·K) | Cost Level | Typical Applications |

|---|---|---|---|

| Alumina (Al₂O₃) | 20–30 | Low–Medium | LED modules, power supplies |

| Aluminum Nitride (AlN) | 150–180 | High | IGBT, EV power modules |

Is Alumina (Al₂O₃) Still the Most Popular Ceramic PCB Material?

Yes. Alumina remains the most widely used ceramic circuit board material for LED and industrial power applications. Alumina ceramic PCB material offers a balanced combination of thermal performance, cost efficiency, and manufacturing maturity.

- Stable and proven manufacturing process

- Excellent electrical insulation

- Compatible with DBC and thick-film technology

When Should You Choose Aluminum Nitride (AlN) Ceramic Substrates?

Aluminum Nitride ceramic circuit board material is selected when maximum thermal conductivity is required to control junction temperature. Compared to Alumina, AlN ceramic PCB material offers significantly lower thermal resistance.

| Parameter | Alumina Ceramic PCB | AlN Ceramic PCB |

|---|---|---|

| Thermal Conductivity | Medium | Very High |

| Cost | Lower | Higher |

| Best Use Case | LED, industrial power | EV, IGBT, RF |

Ceramic Circuit Board Material vs FR4: What Are the Real Differences?

Ceramic circuit board material differs from FR4 mainly in thermal performance, operating temperature, and long-term reliability. Ceramic PCB substrates are designed for power and heat management, while FR4 is designed for signal routing.

| Feature | Ceramic PCB Material | FR4 PCB |

|---|---|---|

| Thermal Conductivity | High | Very Low |

| Max Operating Temperature | >300°C | ~130°C |

| Reliability | Excellent | Limited |

Which Applications Require High-Performance Ceramic Circuit Board Material?

Ceramic PCB material is widely used in applications where heat-related failure is unacceptable.

- High-power LED lighting modules

- Power converters and inverters

- Automotive electronics and EV systems

- Industrial motor drives

- RF and microwave devices

How to Select the Right Ceramic Circuit Board Material for Your Design?

The correct ceramic PCB material is selected through engineering analysis rather than assumptions.

- Calculate power dissipation

- Define maximum junction temperature

- Evaluate cooling conditions

- Select Alumina ceramic PCB material by default

- Upgrade to AlN ceramic PCB material only if required

Why Choosing the Right Ceramic Circuit Board Material Manufacturer Matters?

Choosing a reliable ceramic circuit board material manufacturer is critical because ceramic PCB processing requires specialized equipment and engineering expertise. An experienced ceramic PCB supplier helps reduce risk before mass production.

Why Choose Bstceramic as Your Ceramic Circuit Board Material Manufacturer?

Bstceramic is a professional ceramic circuit board material manufacturer providing reliable ceramic PCB solutions worldwide.

- Expert ceramic material selection support

- Stable Alumina and AlN PCB processes

- Design-for-manufacturing guidance

- Consistent mass-production quality

FAQ

1. What is the best ceramic circuit board material for high-power applications?

Aluminum Nitride ceramic circuit board material is the best choice for extreme high-power applications. Alumina ceramic PCB material is sufficient for most LED and industrial power designs.

2. Is ceramic PCB material better than metal core PCB?

Yes. Ceramic PCB material offers better electrical insulation, higher temperature resistance, and longer service life.

3. Can Alumina ceramic circuit board material handle high-power LEDs?

Yes. Alumina ceramic PCB material is widely used for high-power LED applications due to its balanced performance and cost.

4. How do I choose between Alumina and AlN ceramic PCB material?

Choose Alumina for cost efficiency and AlN when thermal performance is the primary constraint. Thermal simulation should guide the final decision.

Contact Bstceramic Team

If you are sourcing a reliable ceramic circuit board material supplier or manufacturer, Bstceramic is ready to support your project.

Email: sales@bstceramicpcb.com

HOME

HOME