ENEPIG vs ENIG: Which One is Best for Ceramic PCB Surface Finishing?

Surface finish selection plays a decisive role in modern PCB fabrication and assembly. It influences solder joint reliability, component compatibility, long-term corrosion resistance, and even product lifespan. Among the most discussed finishes today, ENEPIG and ENIG are frequently compared because both deliver flat surfaces and strong assembly performance. However, their metallurgical structures and application scenarios are not identical.

This extended guide explores ENEPIG vs ENIG from an engineering perspective. Instead of simply defining each finish, we will examine plating chemistry, assembly behavior, thickness control, reliability risks, and real-world selection strategies.

What Is ENIG Surface Finish and Why Is It Widely Used?

ENIG stands for Electroless Nickel Immersion Gold. It is a chemical deposition process where nickel forms the main barrier layer and gold protects the surface from oxidation.

Typical structure:

- Electroless Nickel: 3–6 µm

- Immersion Gold: 0.05–0.10 µm

The nickel layer provides mechanical strength and prevents copper diffusion into solder joints. The gold layer ensures excellent solderability and protects the nickel during storage.

Advantages of ENIG

ENIG became a mainstream finish because it balances performance and manufacturing cost. Engineers often choose it for HDI boards and fine-pitch assembly because:

- The surface is extremely flat. This helps prevent coplanarity issues in BGA packages.

- It offers consistent solder wetting during reflow.

- Shelf life is longer compared with organic surface finishes.

- The process is mature and widely available globally.

In standard SMT applications, ENIG continues to be one of the most stable and predictable finishes.

What Is ENEPIG and Why Is It Called a “Universal Finish”?

ENEPIG refers to Electroless Nickel Electroless Palladium Immersion Gold. It adds a thin palladium layer between nickel and gold, which significantly changes metallurgical behavior during assembly.

Typical layer structure:

- Nickel: 3–6 µm

- Palladium: 0.05–0.15 µm

- Gold: 0.03–0.05 µm

Although the added palladium thickness is very small, it acts as a diffusion barrier that protects nickel from corrosion and controls intermetallic compound formation during soldering.

Why Choose ENEPIG Surface Treatment?

ENEPIG is often selected when reliability requirements exceed standard SMT needs. It supports multiple assembly technologies, including:

- Gold wire bonding

- Aluminum wire bonding

- Fine-pitch BGA soldering

- Multi-reflow processes

Because of this versatility, ENEPIG is sometimes described as a universal surface finish for high-reliability electronics.

ENEPIG vs ENIG: Key Differences

The main distinction between ENEPIG and ENIG lies in how solder interacts with the nickel layer during reflow.

|

Property |

ENIG |

ENEPIG |

|

Structure |

Nickel + Gold |

Nickel + Palladium + Gold |

|

Nickel Exposure During Reflow |

Direct |

Protected by Palladium |

|

Wire Bond Capability |

Limited |

Excellent |

|

Corrosion Resistance |

Moderate |

High |

|

Black Pad Risk |

Possible |

Significantly Reduced |

When solder melts during reflow, the thin gold layer dissolves rapidly. In ENIG, nickel becomes directly exposed to molten solder. If nickel surface quality is inconsistent, brittle intermetallic layers may form.

In ENEPIG, palladium slows this reaction. The result is smoother IMC growth and more stable solder joints.

ENEPIG vs ENIG Plating Thickness

Thickness directly affects reliability. Too thin gold may reduce shelf life, while excessive nickel can influence stress and warpage.

|

Layer |

ENIG Standard |

ENEPIG Standard |

|

Nickel |

3–6 µm |

3–6 µm |

|

Palladium |

— |

0.05–0.15 µm |

|

Gold |

0.05–0.10 µm |

0.03–0.05 µm |

Because palladium protects the nickel layer, ENEPIG can use less gold while still maintaining oxidation resistance. This sometimes offsets material costs.

ENEPIG vs ENIG Reliability Under Thermal Stress

Thermal cycling is a common reliability challenge, especially for AI servers and automotive electronics.

ENIG Behavior During Thermal Cycling

Repeated heating and cooling can accelerate nickel corrosion if plating quality is inconsistent. Over time, brittle fractures may appear at the solder interface.

ENEPIG Behavior

Palladium stabilizes the nickel layer, reducing corrosion risk. This leads to:

- Better drop shock resistance

- Improved thermal fatigue performance

- More stable solder joint morphology

These benefits explain why ENEPIG is frequently used in aerospace, medical electronics, and high-power modules.

Cost Comparison: ENEPIG vs ENIG in Real Production

|

Cost Factor |

ENIG |

ENEPIG |

|

Process Complexity |

Medium |

Higher |

|

Gold Usage |

Higher |

Lower |

|

Assembly Yield |

Standard |

Often Improved |

|

Suitability for Advanced Packages |

Moderate |

Excellent |

While ENEPIG requires more process steps, it may reduce assembly defects in advanced designs. For high-value products, this can improve overall cost efficiency.

Typical Applications of ENIG Surface Finish

ENIG remains a preferred choice for many mainstream electronics because it offers stable performance.

Common ENIG applications:

- Consumer electronics PCBs

- Communication equipment

- Industrial control boards

- Standard HDI designs

If the design relies only on soldering without wire bonding, ENIG often delivers excellent results.

Typical Applications Where ENEPIG Excels

ENEPIG becomes more attractive as design complexity increases.

Typical ENEPIG applications include:

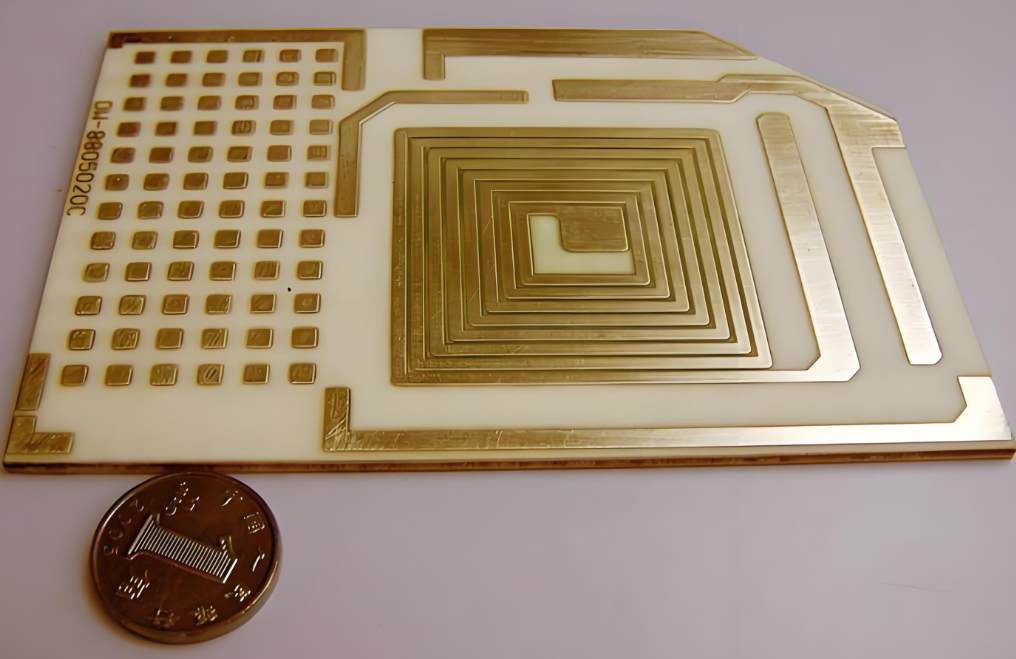

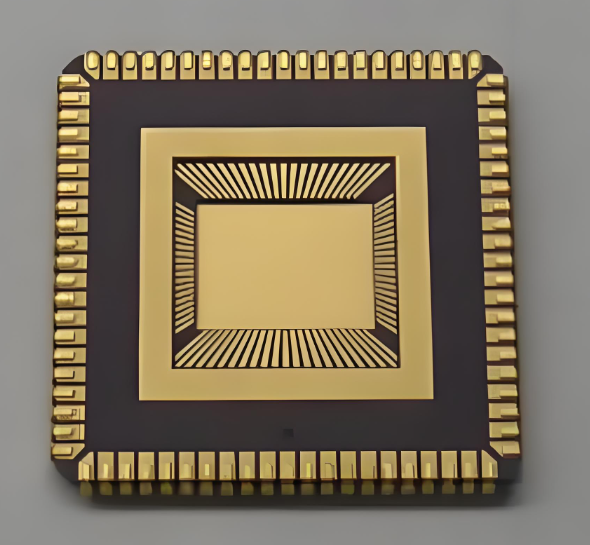

- Semiconductor packaging substrates

- RF modules

- AI server accelerator boards

- Automotive control systems

- Medical implant electronics

These environments demand high reliability and stable metallurgical behavior.

ENEPIG vs ENIG for AI Server PCB and High-Speed Designs

AI server boards often feature dense routing, fine-pitch components, and multiple reflow cycles. These conditions place stress on surface finishes.

ENEPIG’s palladium layer helps maintain solder joint integrity under these conditions. It also improves compatibility with advanced packaging technologies such as chip-on-board and high-density interconnect structures.

As AI hardware evolves toward higher power density, ENEPIG adoption continues to grow.

How to Decide Between ENEPIG and ENIG in Ceramic PCB Design?

A practical selection strategy begins with assembly requirements rather than cost alone.

Choose ENIG when:

- Assembly uses only SMT soldering

- Reliability requirements are moderate

- Production volume is large and cost-sensitive

Choose ENEPIG when:

- Wire bonding is required

- Product must survive harsh environments

- High-layer HDI or advanced packaging is involved

- Long service life is critical

Early collaboration between PCB designers and manufacturing engineers helps avoid redesign costs later.

FAQs

Is ENEPIG replacing ENIG completely?

No. ENIG remains widely used. ENEPIG is mainly adopted in advanced applications.

Does ENEPIG eliminate black pad risk?

It significantly reduces the risk because palladium protects the nickel surface.

Is ENEPIG better for fine-pitch BGA assembly?

Yes. The flat surface and stable metallurgy support high-density packages.

Can ENEPIG reduce gold consumption?

Yes. Palladium allows thinner gold layers while maintaining performance.

Does ENEPIG require different reflow profiles?

Usually not. Standard SMT profiles are compatible with ENEPIG finishes.

If you have any questions about ENIG surface finishing or ENEPIG, welcome to contact us at sales@bstceramicpcb.com.

HOME

HOME