Ceramic PCB Linewidth and Line Spacing

Technical Standards, Industry Requirements and Precision Manufacturing Solutions Introduction

As Germany continues to lead Europe in advanced manufacturing, automotive electronics, industrial automation, and high-reliability power systems, ceramic PCBs are playing an increasingly critical role. Compared with traditional FR-4 boards, ceramic substrates such as alumina (Al₂O₃) and aluminum nitride (AlN) offer superior thermal conductivity, electrical insulation, and dimensional stability.

Within ceramic PCB design and fabrication, linewidth and line spacing are among the most decisive technical parameters. They directly influence electrical performance, thermal behavior, reliability, and manufacturability. For German OEMs and Tier-1 suppliers, where compliance, repeatability, and process transparency are essential, understanding and controlling these parameters is not optional—it is a baseline requirement.

This article provides an in-depth analysis of ceramic PCB linewidth and line spacing requirements for the German market, integrating European and German standards, industry-specific expectations, and proven manufacturing strategies. It also explains how BSTCERAMICPCB supports German customers with precision ceramic PCB solutions from design to mass production.

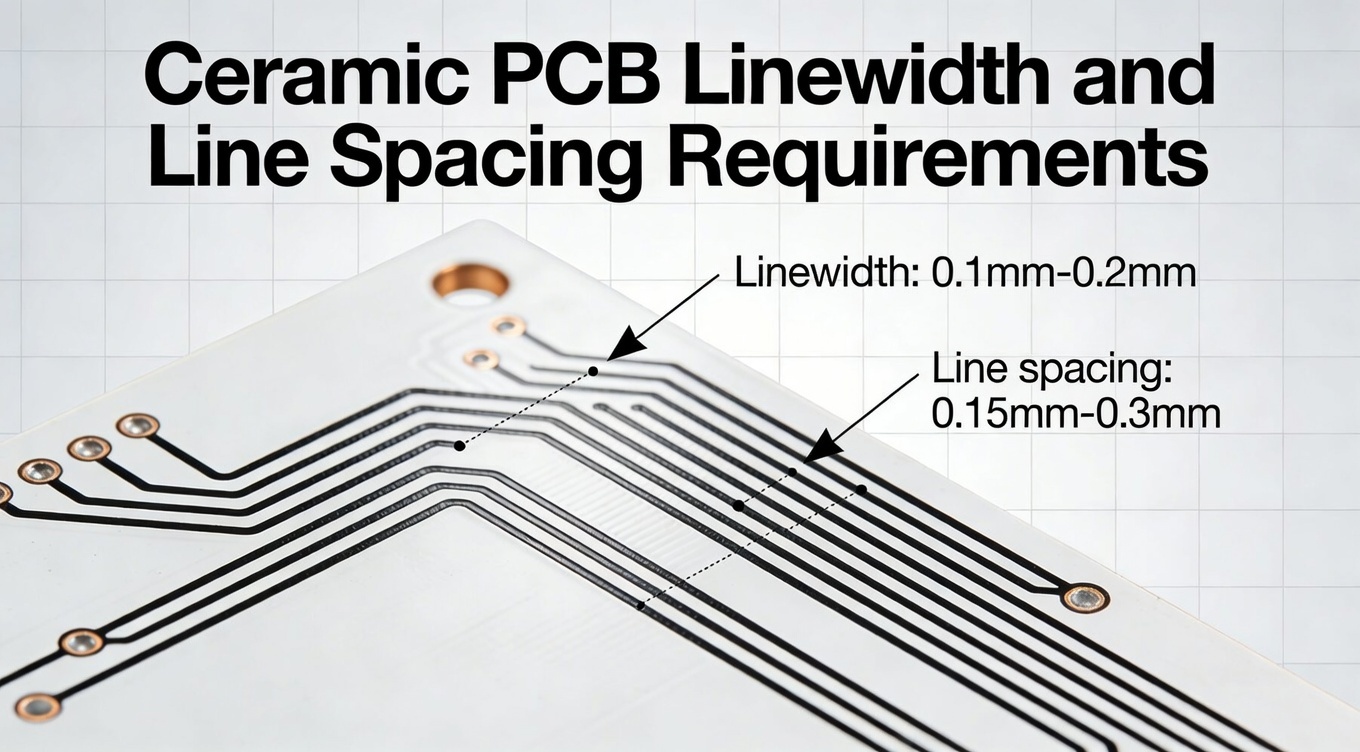

Understanding Linewidth and Line Spacing in Ceramic PCB Design

In ceramic PCB technology, linewidth refers to the width of the conductive trace deposited on the ceramic substrate, while line spacing defines the minimum distance between adjacent conductive features. Although these concepts are familiar to PCB engineers, their implications are fundamentally different when applied to ceramic materials.

Unlike organic laminates, ceramic substrates are rigid, brittle, and processed using metallization techniques such as thick-film printing, DBC (Direct Bonded Copper), or AMB (Active Metal Brazing). Each process imposes specific limits on how fine or wide traces can be produced consistently. In Germany’s high-precision electronics environment, these limits must be clearly understood during the design phase.

From a functional perspective, linewidth and line spacing affect:

- Current-carrying capacity, especially in power and automotive applications

- Electrical insulation and creepage distance, critical for safety compliance

- Signal integrity, particularly in high-frequency and control circuits

- Thermal distribution, as copper geometry influences heat spreading

German manufacturers typically demand predictable, repeatable results rather than aggressive minimum features. Therefore, optimal ceramic PCB design often balances electrical requirements with process robustness and yield stability, rather than pushing theoretical limits.

Technical Requirements and Industry Standards in Germany

Germany follows a combination of international IPC standards, European norms, and industry-specific regulations when defining acceptable linewidth and line spacing for ceramic PCBs.

From a general perspective, IPC-6012 and IPC-2221 provide baseline guidance for conductor geometry, spacing, and insulation. However, in ceramic PCB applications, these guidelines are often adapted to account for ceramic-specific properties such as thermal expansion mismatch and metallization adhesion strength.

German standards and practices typically emphasize:

- Electrical clearance and creepage under high voltage

- Long-term reliability under thermal cycling

- Dimensional stability over extended operating lifetimes

In many German industrial and automotive projects, conservative spacing rules are preferred. For example, while a ceramic PCB process may technically support very fine spacing, German OEMs often specify larger margins to ensure compliance with VDE, IEC, or customer-specific reliability requirements.

Material selection also directly impacts achievable geometry. Alumina substrates generally allow stable, medium-fine linewidths suitable for industrial control and sensor electronics. Aluminum nitride, with its higher thermal conductivity, is often used in power electronics but requires stricter process control to maintain consistent line definition.

At BSTCERAMICPCB, linewidth and spacing capabilities are clearly defined during DFM review, ensuring that German customers receive realistic, production-proven design rules rather than laboratory-only values.

Ceramic PCB Linewidth and Line Spacing Requirements by Industry in Germany

Automotive Electronics

Germany’s automotive sector places extremely high demands on ceramic PCB reliability. In applications such as power modules, sensors, and control units, linewidth and line spacing must support:

- High current density

- Long-term vibration resistance

- Compliance with ISO 26262 functional safety requirements

Automotive ceramic PCBs typically prioritize robust copper geometry over ultra-fine features. Wider traces and sufficient spacing reduce the risk of micro-cracking, delamination, or insulation degradation during thermal cycling.

Industrial Automation and Power Electronics

Industrial drives, inverters, and control systems often operate continuously under elevated temperatures. In these cases, linewidth is closely linked to thermal dissipation, while line spacing ensures safe operation under high voltage.

German industrial customers frequently request conservative spacing values combined with thick copper layers to achieve stable performance over decades of service life.

Telecommunications and High-Frequency Modules

For RF and communication equipment, signal integrity becomes a dominant factor. Controlled impedance traces, consistent linewidth, and precise spacing are essential to minimize signal loss and interference.

Ceramic substrates offer excellent dielectric stability, but achieving tight tolerances requires close collaboration between design engineers and manufacturers. BSTCERAMICPCB supports this process through early-stage design consultation and prototype validation.

Medical and Precision Electronics

Medical devices in Germany are governed by strict regulatory frameworks. Ceramic PCBs used in imaging, diagnostics, or monitoring equipment must demonstrate both electrical precision and manufacturing repeatability.

Here, linewidth and spacing decisions are driven by reliability and certification readiness rather than cost optimization.

Design Tradeoffs and Best Practices for High-Precision Ceramic PCBs

Designing ceramic PCBs for the German market requires careful tradeoffs. Narrow linewidths may enable compact layouts, but they also increase process sensitivity. Similarly, minimal spacing can improve density but may compromise insulation reliability under high voltage or humidity.

Best practices include:

- Selecting linewidths that align with proven manufacturing windows

- Allowing sufficient spacing for voltage and environmental conditions

- Considering metallization thickness and surface finish effects

- Performing DFM reviews before finalizing layouts

German customers increasingly value design for manufacturability (DFM) as part of supplier evaluation. A ceramic PCB supplier is expected not only to fabricate boards but also to provide engineering feedback that improves yield and reliability.

BSTCERAMICPCB integrates DFM analysis into every project, helping German clients optimize linewidth and spacing based on real production data rather than assumptions.

Why German Customers Choose BSTCERAMICPCB

For German OEMs and EMS providers, supplier selection is based on technical credibility, transparency, and long-term stability. BSTCERAMICPCB has built its ceramic PCB manufacturing process to align with these expectations.

Key advantages include:

- Clearly defined linewidth and line spacing capabilities for different ceramic processes

- Engineering-led communication with detailed DFM feedback

- Stable production processes for alumina and aluminum nitride substrates

- Quality inspection systems designed to meet European reliability expectations

By combining material expertise, process control, and application-level understanding, BSTCERAMICPCB supports German customers from prototype development to volume production.

For companies seeking reliable ceramic PCB linewidth and line spacing solutions tailored to German industry standards, partnering with an experienced manufacturer reduces risk, shortens development cycles, and improves long-term product performance.

Conclusion and Next Steps

As Germany continues to demand higher reliability, precision, and compliance in electronic systems, ceramic PCB linewidth and line spacing will remain a critical design and manufacturing focus. Understanding how these parameters interact with materials, processes, and industry standards is essential for successful projects.

BSTCERAMICPCB offers German customers a proven path to precision ceramic PCB manufacturing, combining technical depth with practical production experience.

HOME

HOME