-

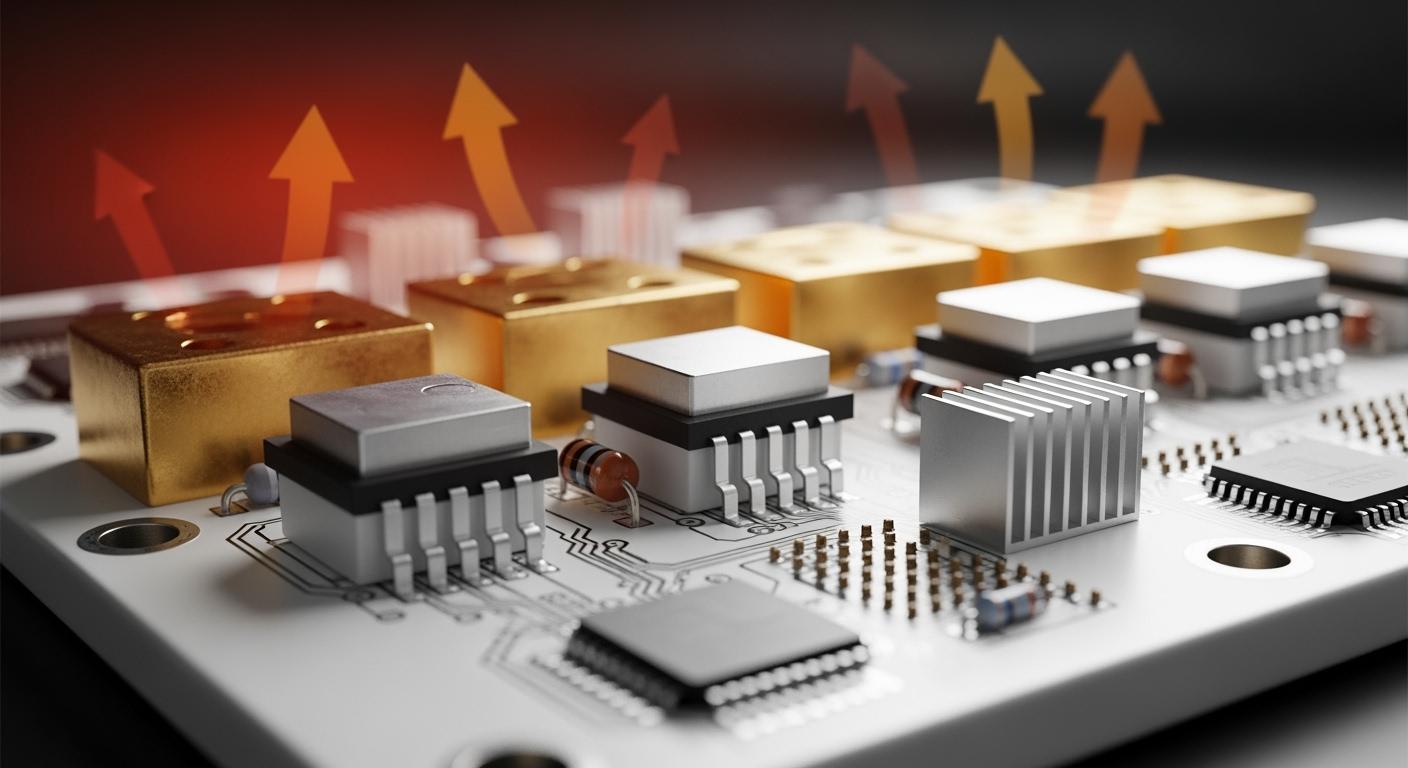

Ceramic Circuit Board Design for the UK Electronics Industry

Explore professional ceramic circuit board design for the UK market. Learn materials, DFM, thermal performance, and how BST Ceramic PCB supports aerospace, EV, and industrial electronics. 2026-01-13 -

High Thermal Conductivity Ceramic PCB for Photovoltaic Applications

High thermal conductivity ceramic PCB solutions for photovoltaic and solar applications. Flexible PCB and rigid-flex designs for high-power, reliable energy systems. 2026-01-12 -

High-Thermal Beryllium Oxide (BeO) Circuit Boards: Powering Germany’s Photovoltaic Future

Leading BeO circuit board solutions for German PV inverters and concentrated solar power. Explore high-conductivity BeO ceramic PCBs, Rigid-Flex, and FPC designs. 2026-01-10 -

Aluminum Nitride (AlN) Circuit Boards: Revolutionizing Thermal Management in UK Energy Storage Systems

Discover BST Ceramic PCB’s Aluminum Nitride (AlN) solutions for UK energy storage. High thermal conductivity for power modules, FPC, and Rigid-Flex integration. 2026-01-10 -

Thermal Shock Resistance of Ceramic Circuit Boards: The Ultimate Guide for Kiwi Innovators

Discover the secrets of thermal shock resistance of ceramic circuit boards. Essential guide for NZ AgriTech & Aerospace engineers. Upgrade with BST Ceramic. 2026-01-07 -

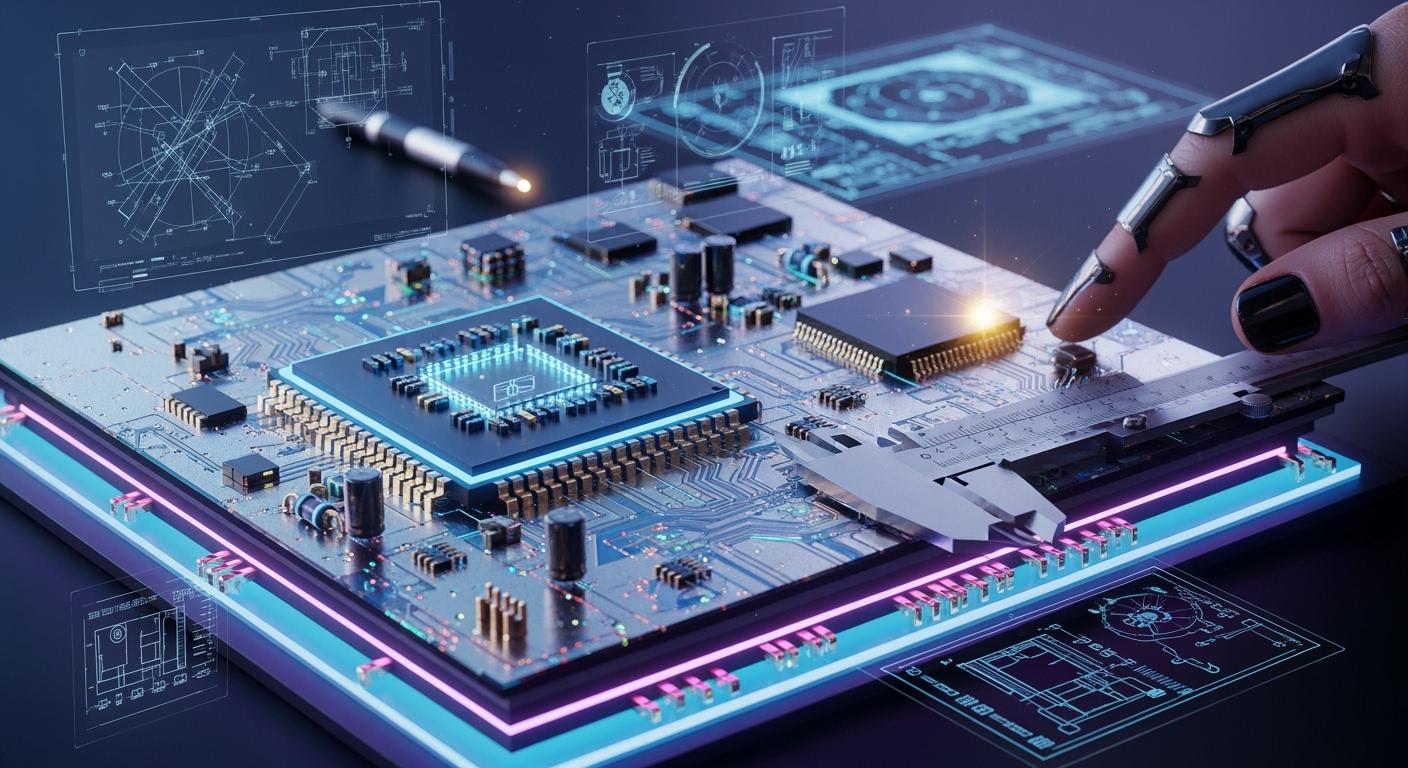

Top Tips for Advanced Semiconductor Packaging Substrate Design

Materials with high adhesion and robust thermal properties help you achieve reliable performance. Recent industry reports highlight how emerging technologies in semiconductor packaging enhance device integration and system-level performance. 2026-01-05 -

Automotive electronic ceramic circuits make cars smarter and safer

Imagine you are driving a car that reacts very fast to road changes. Your car uses automotive electronic ceramic circuits with LTCC technology. These circuits take in data from sensors. They help you stay away from danger. These circuits also make smart features work, like adaptive headlights and collision alerts. You get better safety and trust your car more each time you drive. 2026-01-05 -

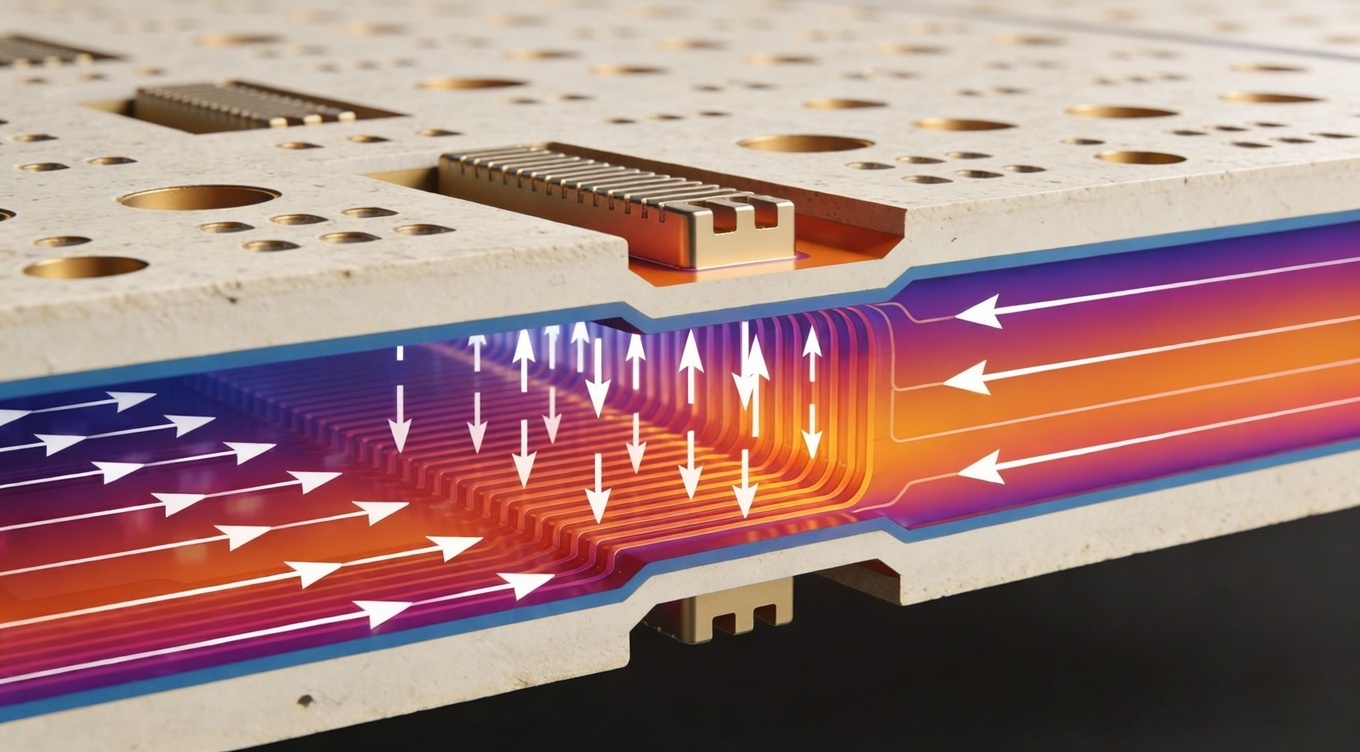

Ceramic PCB for Power Modules (IGBT): The Ultimate High-Thermal Management Guide

BST Ceramic PCB offers high-performance ceramic substrates for IGBT power modules. Specializing in AlN and Al2O3 with DBC/AMB technology for German automotive and renewable energy sectors. IATF 16949 certified. Get high thermal conductivity solutions today. 2025-12-27 -

Ceramic Substrate or Aluminum PCB for High-Power LEDs

You want your high-power LEDs to work well. High-power LED ceramic substrate PCB gives you great heat transfer and is very reliable. This choice is good for tough places but costs more money. Aluminum PCBs are cheaper and still spread heat well. You should think about your budget, how long you need the LEDs to last, and where you will use them. 2025-12-24

HOME

HOME